Pipeline transportation method for easy-condensing high-viscous crude oil after degraded by microorganism

A high-viscosity crude oil and pipeline transportation technology, which is applied in the pipeline system, petroleum industry, refined hydrocarbon oil, etc., can solve the problems of environmental pollution, unstable pour point depressing effect, etc., and achieve the effect of reducing the cost of use and the probability of pipeline blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

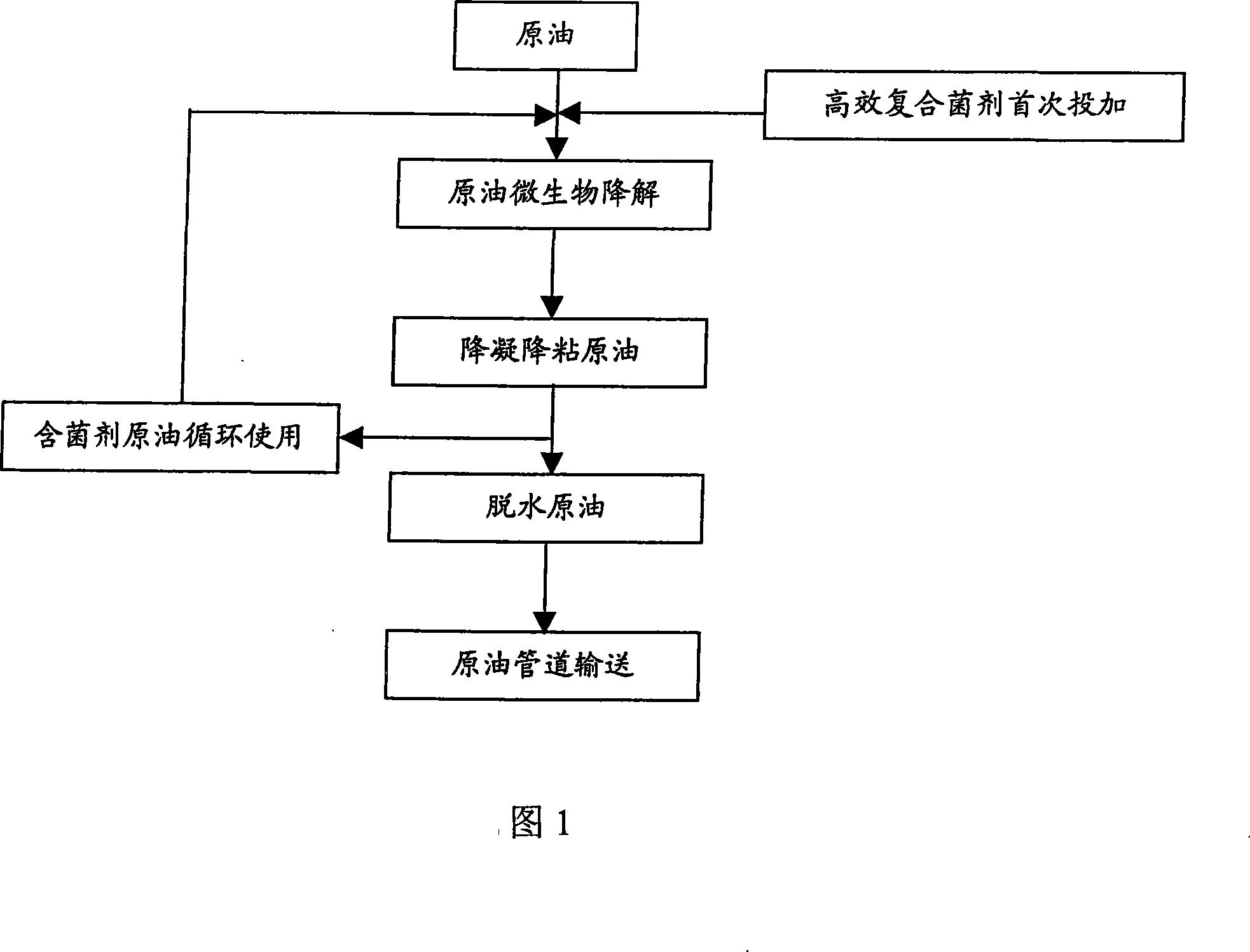

Method used

Image

Examples

Embodiment 1

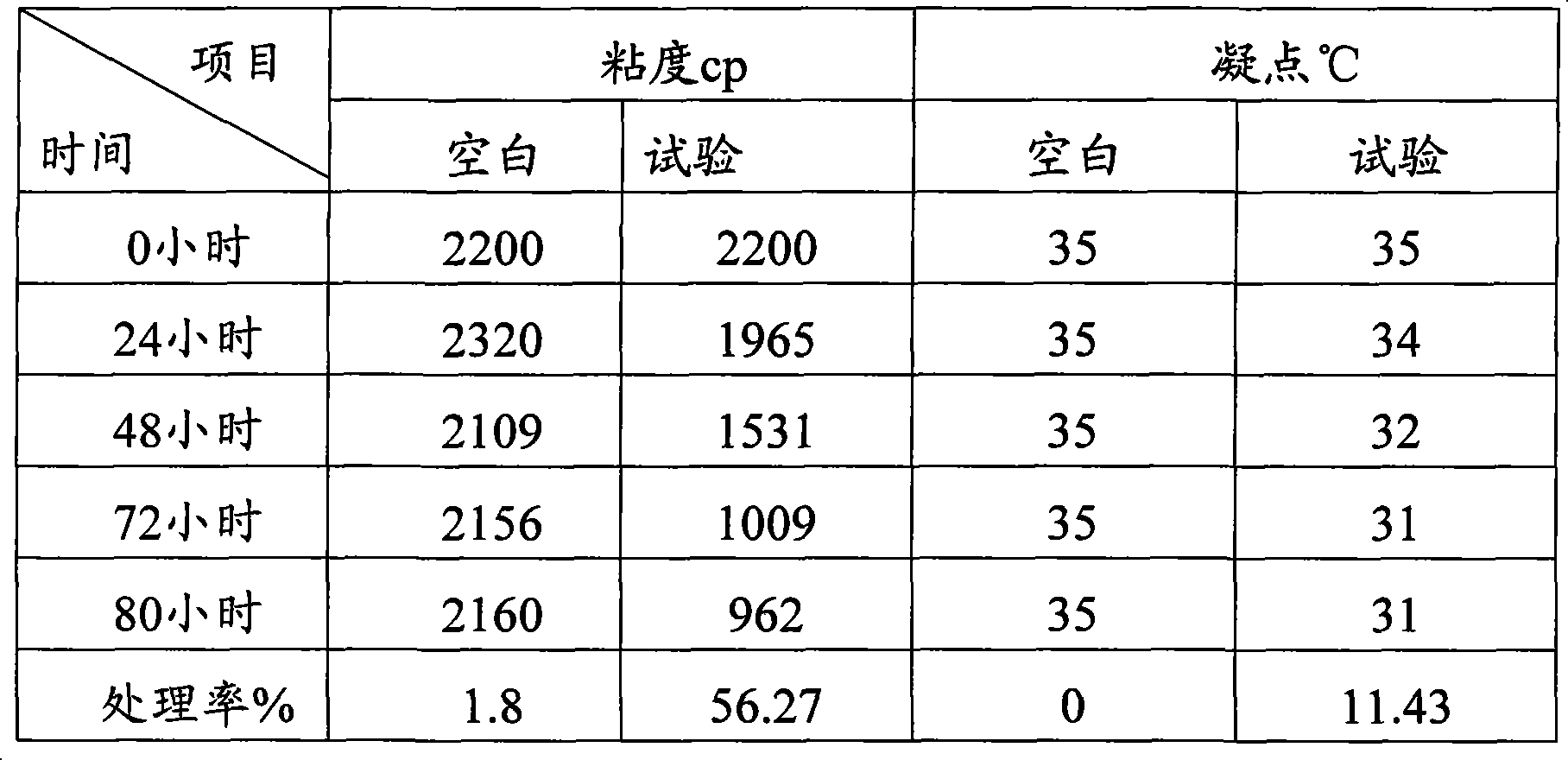

[0023] Microbial pour point and viscosity drop small test, the specific implementation steps are as follows:

[0024] (1) 300g of crude oil, mixing ratio mixed liquid: crude oil=1:1, then the weight of mixed liquid is 300g.

[0025] (2) In the mixed solution, compound bacterial liquid: nutrient solution = 1:4, calculated according to this ratio, the compound bacterial liquid needs 60g, and the nutrient solution needs 240g.

[0026] (3) The composite bacterial liquid includes three microbial bacterial liquids of Pseudomonas genus G3, Bacillus genus B5, and Corynebacterium genus Y2. The three bacterial liquids are mixed in a weight ratio of 4:3:2, and the calculation is based on 60 g of the composite bacterial liquid , the weight of the three kinds of bacteria liquid is: Pseudomonas G3 27g, Bacillus B5 20g, Corynebacterium Y2 13g, pH7.0, cell concentration of 10 9 individual / ml.

[0027] (4) The composition of the nutrient solution is: molasses: 1%, (NH 4 ) 2 SO 4 0.1%, Mg...

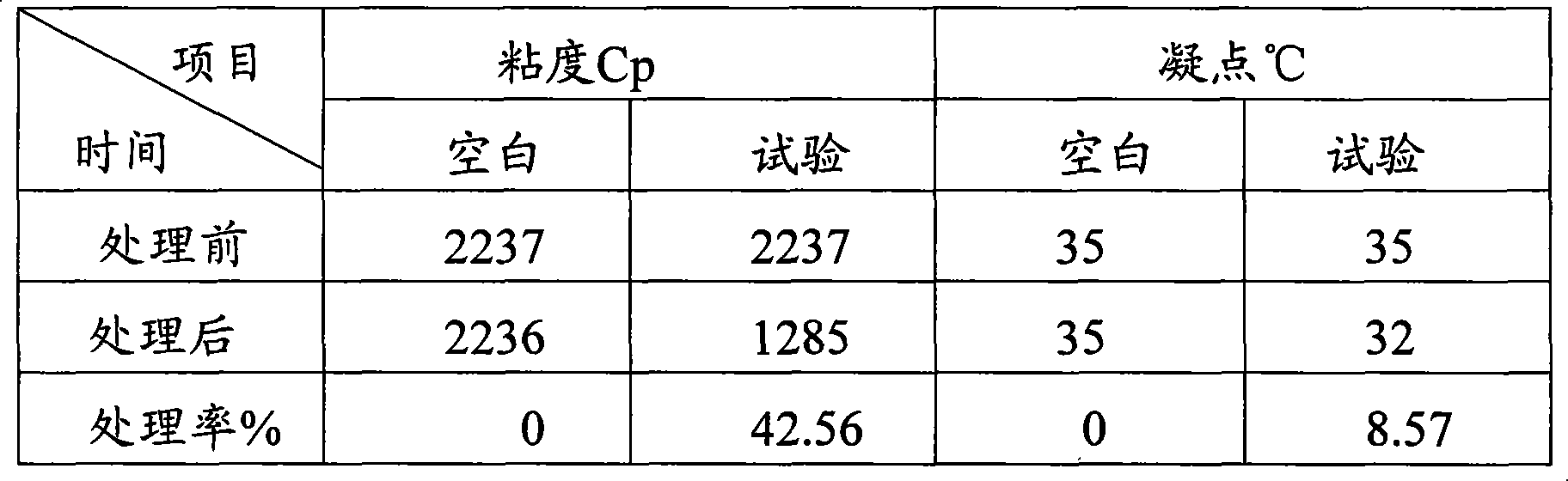

Embodiment 3

[0048] The above test can also be completed through other mixing ratios and conditions, and better delivery effects can be obtained. Calculated as 1 ton according to the transport scale, the specific calculation method of each component content is limited according to the requirements of the present invention, and the calculation results are shown in Table 3.

[0049] table 3:

[0050] Mixture: crude oil

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com