Organic processing technique for bamboo fibre

A processing technology, bamboo fiber technology, applied in fiber treatment, fiber chemical post-treatment, textiles and papermaking, etc., can solve the problems of low wool efficiency of fabrics, resistance to strong alkali, unclean removal of cotton seed husks, etc., and achieve resilience And good wear resistance, good drapability, excellent coloring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

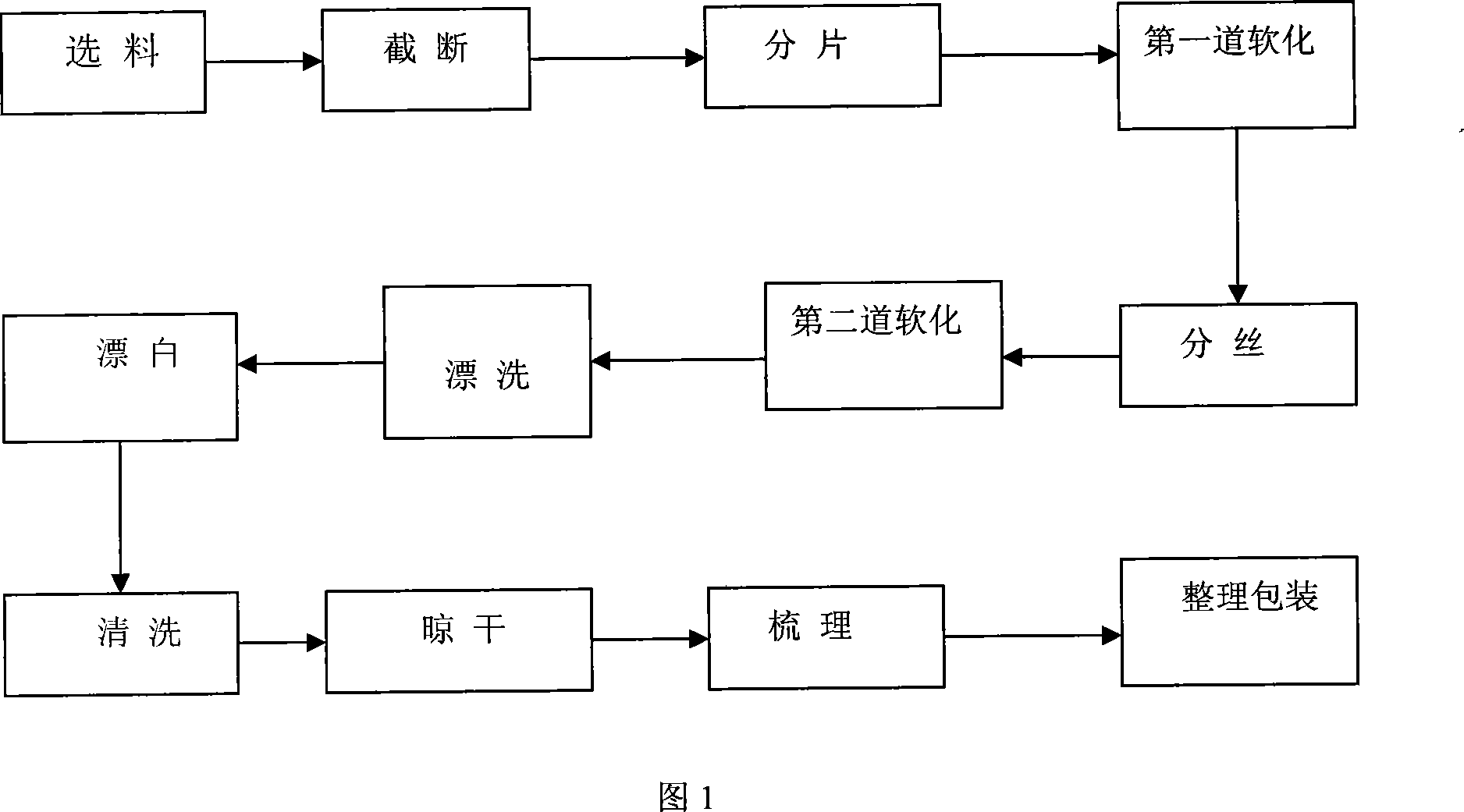

[0012] Embodiment 1: this bamboo fiber organic processing technique comprises successively that the bamboo material of bamboo forest base is classified and selected; By material selection classification, cut off respectively; Bamboo material is sliced according to bamboo yellow and bamboo green; The first step is softened; The silk machine separates the cooked bamboo green and bamboo yellow separately; the second softening; rinsing; bleaching; the bleached bamboo fiber is washed and dried in an industrial washing machine; the bleached bamboo fiber is dried outdoors Drying, so that its moisture is controlled at a humidity below 20%; the dried bamboo fibers are shaken and evenly put into a carding machine for carding; finishing and packaging processes.

[0013] The first softening process is to heat and cook the green bamboo and the yellow bamboo respectively in the softening liquid that can completely submerge the bamboo slices, wherein the green bamboo is heated and steamed f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com