Thermosetting epoxy resin coloring master batch as well as preparation process and application thereof

A technology of epoxy resin and coloring masterbatch, which is applied in the direction of epoxy resin coating, coating, powder coating, etc., can solve the problems of uneven mixing, uneven pigment dispersion, color and color difference, etc., and achieve good appearance performance and coloring Good performance and uniform coloring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

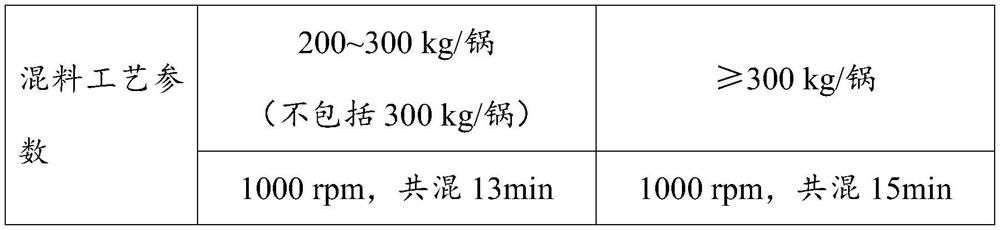

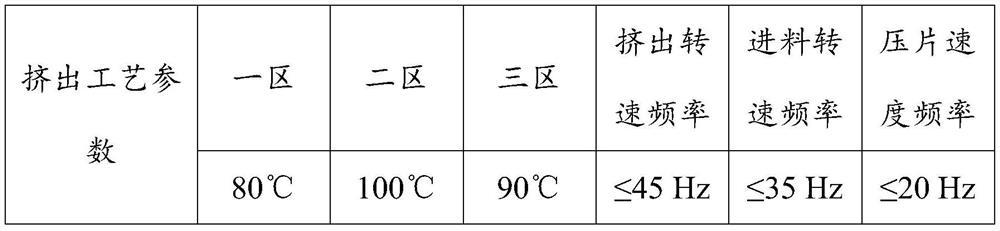

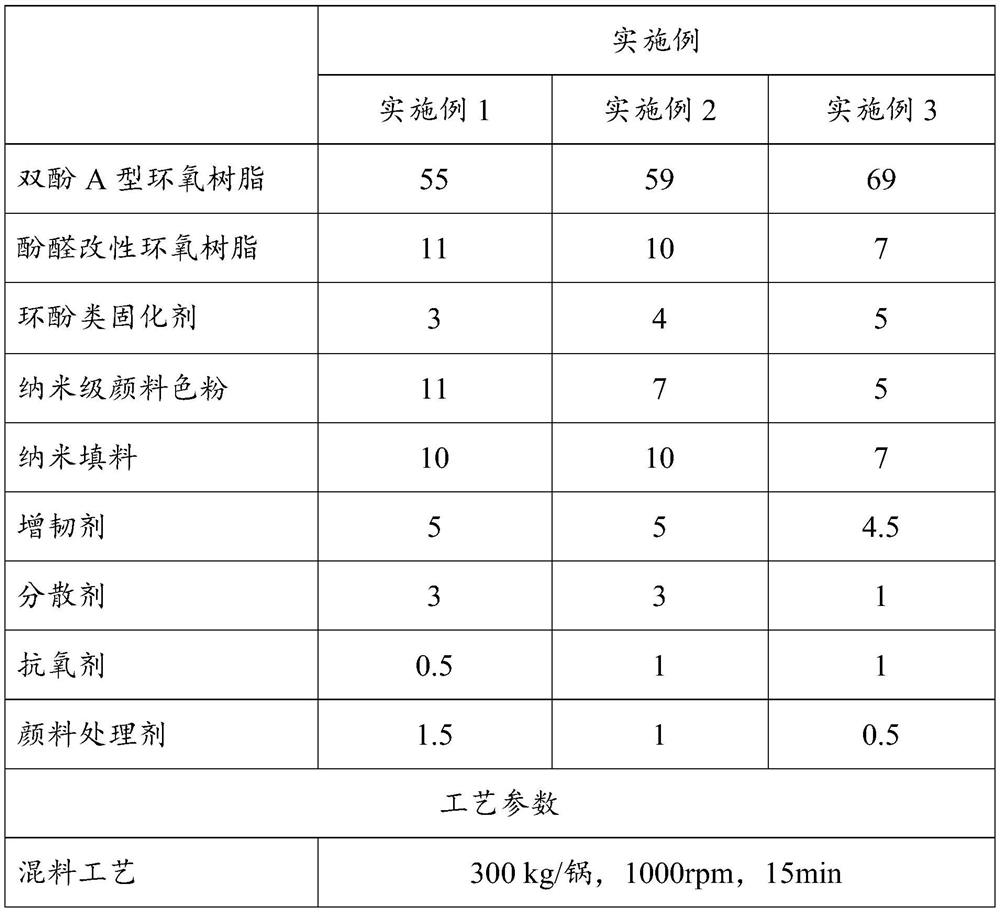

Embodiment 1

[0055] Thermosetting epoxy resin coloring masterbatch, raw materials are measured in parts by mass, 55 parts of bisphenol A epoxy resin (bisphenol A solid epoxy resin 907); 11 parts of phenolic modified epoxy resin (E-12 resin); Cyclophenolic curing agent (resin curing agent 969F02X) 3 parts; nano-scale pigment toner (Swiss Klein pigment) 11 parts; nano-filler (high light barium sulfate) 10 parts; toughening agent (toughening plasticizer TL815) 5 parts 3 parts; 3 parts of dispersant (Robotec YY-2012 bright dispersant); 0.5 parts of antioxidant (antioxidant 215); 1.5 parts of pigment treatment agent (silane coupling agent).

[0056] The process of preparing thermosetting epoxy resin coloring masterbatch is as follows: lift each raw material to the airtight feeding room by elevator, manually add each raw material in the feeding port; close the feeding port after feeding, and mix the materials. After stirring for 15 minutes, the mixed materials pass through the airtight The gravi...

Embodiment 2

[0058] Thermosetting epoxy resin coloring masterbatch, raw materials are measured in parts by mass, 59 parts of bisphenol A epoxy resin (bisphenol A solid epoxy resin 907); 10 parts of phenolic modified epoxy resin (E-12 resin); Cyclophenolic curing agent (resin curing agent 969F02X) 4 parts; nano-scale pigment toner (Swiss Klein pigment) 7 parts; nano-filler (high light barium sulfate) 10 parts; toughening agent (toughening plasticizer TL815) 5 parts 3 parts; 3 parts of dispersant (Robotec YY-2012 bright dispersant); 1 part of antioxidant (antioxidant 215); 1 part of pigment treatment agent (silane coupling agent).

[0059] The process of preparing thermosetting epoxy resin coloring masterbatch is as follows: lift each raw material to the airtight feeding room by elevator, manually add each raw material in the feeding port; close the feeding port after feeding, and mix the materials. After stirring for 15 minutes, the mixed materials pass through the airtight The gravity flow...

Embodiment 3

[0061] Thermosetting epoxy resin coloring masterbatch, raw materials are measured in parts by mass, 69 parts of bisphenol A type epoxy resin (bisphenol A solid epoxy resin 907); 7 parts of phenolic modified epoxy resin (E-12 resin); Cyclophenolic curing agent (resin curing agent 969F02X) 5 parts; nano-scale pigment toner (Swiss Klein pigment) 5 parts; nano-filler (high light barium sulfate) 7 parts; toughening agent (toughening plasticizer TL815) 4.5 1 part; 1 part of dispersant (Robotec YY-2012 bright dispersant); 1 part of antioxidant (antioxidant 215); 0.5 part of pigment treatment agent (silane coupling agent).

[0062] The process of preparing thermosetting epoxy resin coloring masterbatch is as follows: lift each raw material to the airtight feeding room by elevator, manually add each raw material in the feeding port; close the feeding port after feeding, and mix the materials. After stirring for 15 minutes, the mixed materials pass through the airtight The gravity flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com