Halogen-free flame-retardant antistatic PC material and preparation method thereof

A technology of flame retardant, antistatic and antistatic agent, applied in the field of polycarbonate materials, can solve the problems of easy agglomeration of conductive fillers, single color, PC degradation, etc., and achieve excellent flame retardant effect, excellent antistatic performance and flame retardant performance. , easy to color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

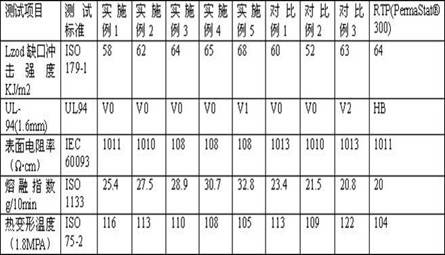

Examples

Embodiment Construction

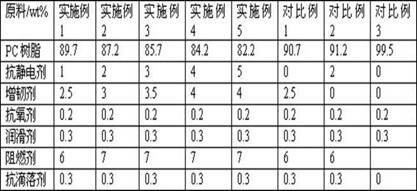

[0030] A halogen-free flame-retardant antistatic PC material and a preparation method thereof, comprising the following raw materials in mass percentage:

[0031] C resin 70%-90%

[0032] Antistatic agent 1%-5%

[0033] Flame retardant 5%-10%

[0034] Toughener 2%-4%

[0035] Antioxidant 0.2%-0.5%

[0036] Lubricant 0.2%-0.5%

[0037] Anti-dripping agent 0.1%-0.4%.

[0038] Preferably, for this halogen-free flame-retardant and antistatic PC material, the melt index of the PC resin under the condition of 300°C and 1.2kg is 10g / 10min-25g / 10min. Here we use Luxi's grade PC1920.

[0039] Preferably, in this halogen-free flame-retardant antistatic PC material, the antistatic agent is sodium alkylsulfonate.

[0040] Preferably, in this halogen-free flame-retardant antistatic PC material, the toughening agent is MBS.

[0041] Preferably, for this halogen-free flame-retardant antistatic PC material, the antioxidant is compounded with 1076 and 168 in a ratio of 1:1.

[0042] P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com