Gyration type sludge desiccation material-feeding device for sludge burning furnace

A sludge incineration and feeding device technology, which is applied to incinerators, sludge treatment through temperature control, packaging, etc., can solve the problems of many transportation links and auxiliary equipment, large heat loss, and low reliability, so as to save Auxiliary power equipment, reduced heat loss, and improved operational reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

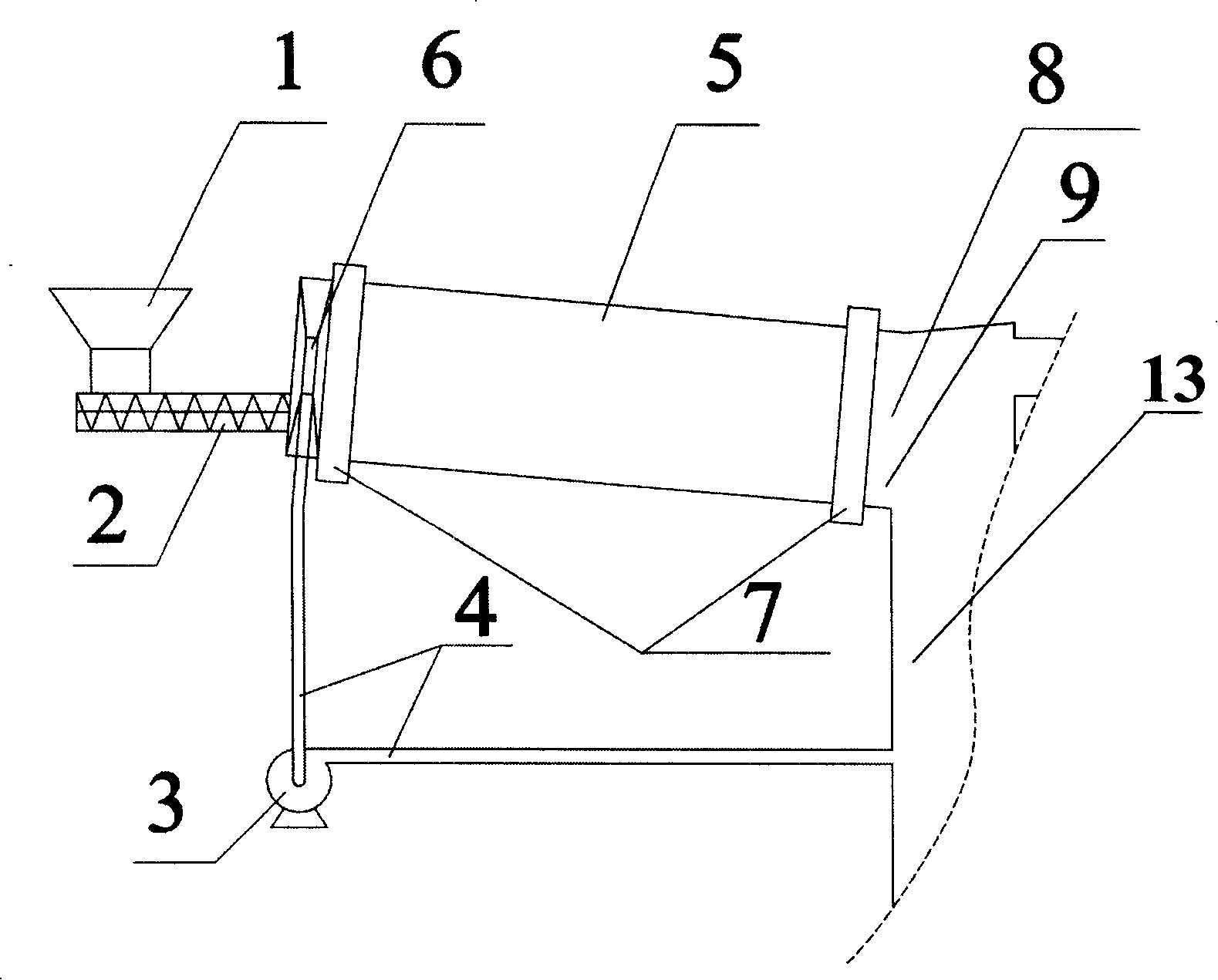

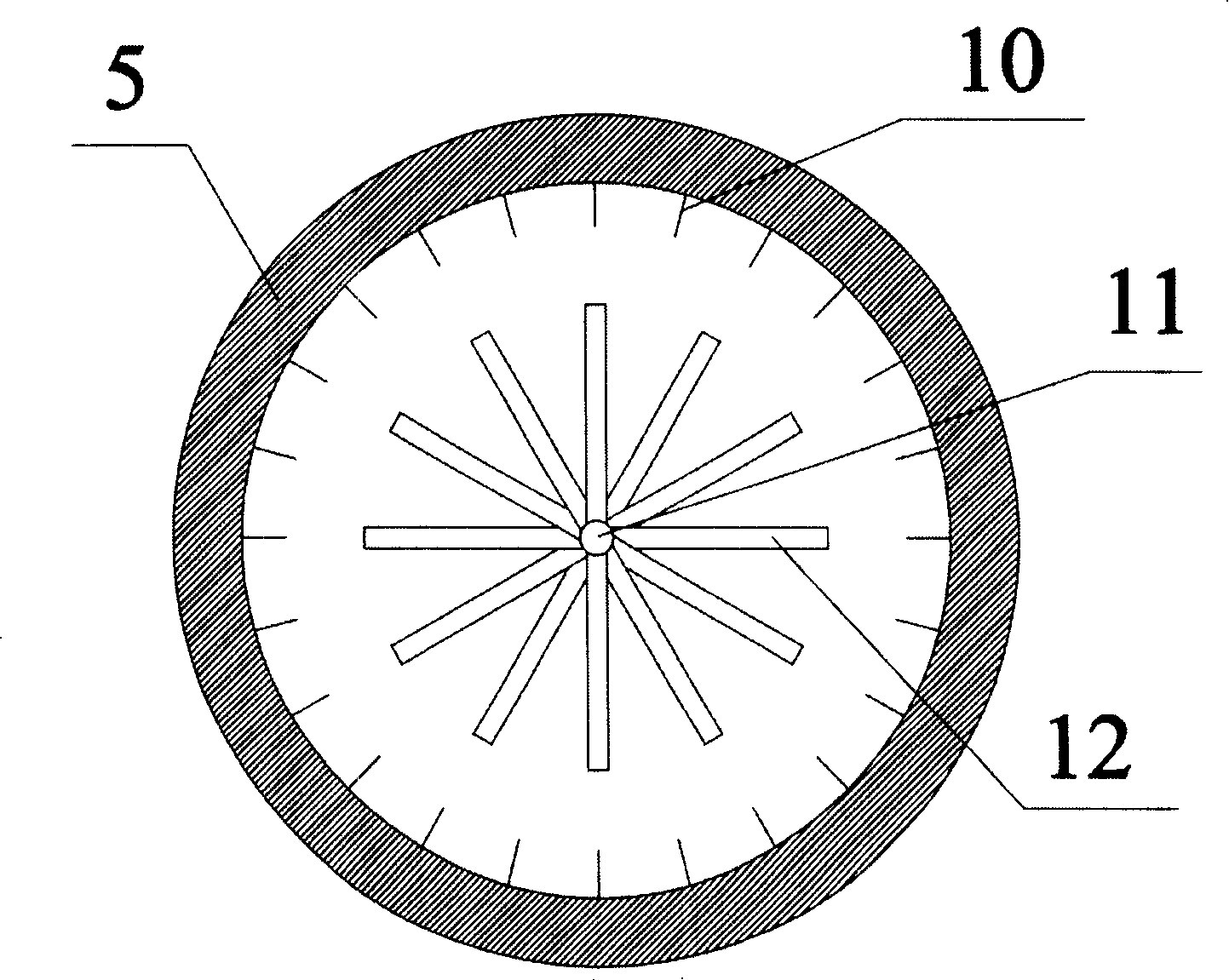

[0013] like figure 1 As shown, the rotary sludge drying feeding device for sludge incinerator of the present invention is composed of a hopper 1, a screw feeder 2, a rotary cylinder 5 and a bracket 7, and the screw feeder 2 has a feed end and a discharge end, wherein the rotary cylinder 5 is arranged in the support 7, and the front end of the rotary cylinder 5 is connected to the discharge end of the screw feeder 2, The hopper 1 is connected to the feeding end of the screw feeder 2, and the front end of the rotary cylinder 5 is provided with a flue gas outlet 6, and the flue gas outlet 6 is connected with a flue gas pipe 4, the flue gas pipe A flue gas circulation fan 3 is arranged in 4, and a flue gas inlet 8 is arranged in the rear end outlet 9 of the rotary cylinder 5 . like figure 2 As shown, a plurality of inner fins 10 are arranged at intervals on the inner wall circumference of the rotary cylinder 5, and the length direction of any one of the inner fins 10 is paralle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com