Method for preparing synthetic gas by gasifying biological oil and device thereof

A technology for synthesis gas and bio-oil, which is applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problem of no substantive research, no use of pressurized gas flow bed bio-oil gasification reaction, and no synthesis gas preparation. problems, to reduce complex problems, reduce tar and methane content, and facilitate collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

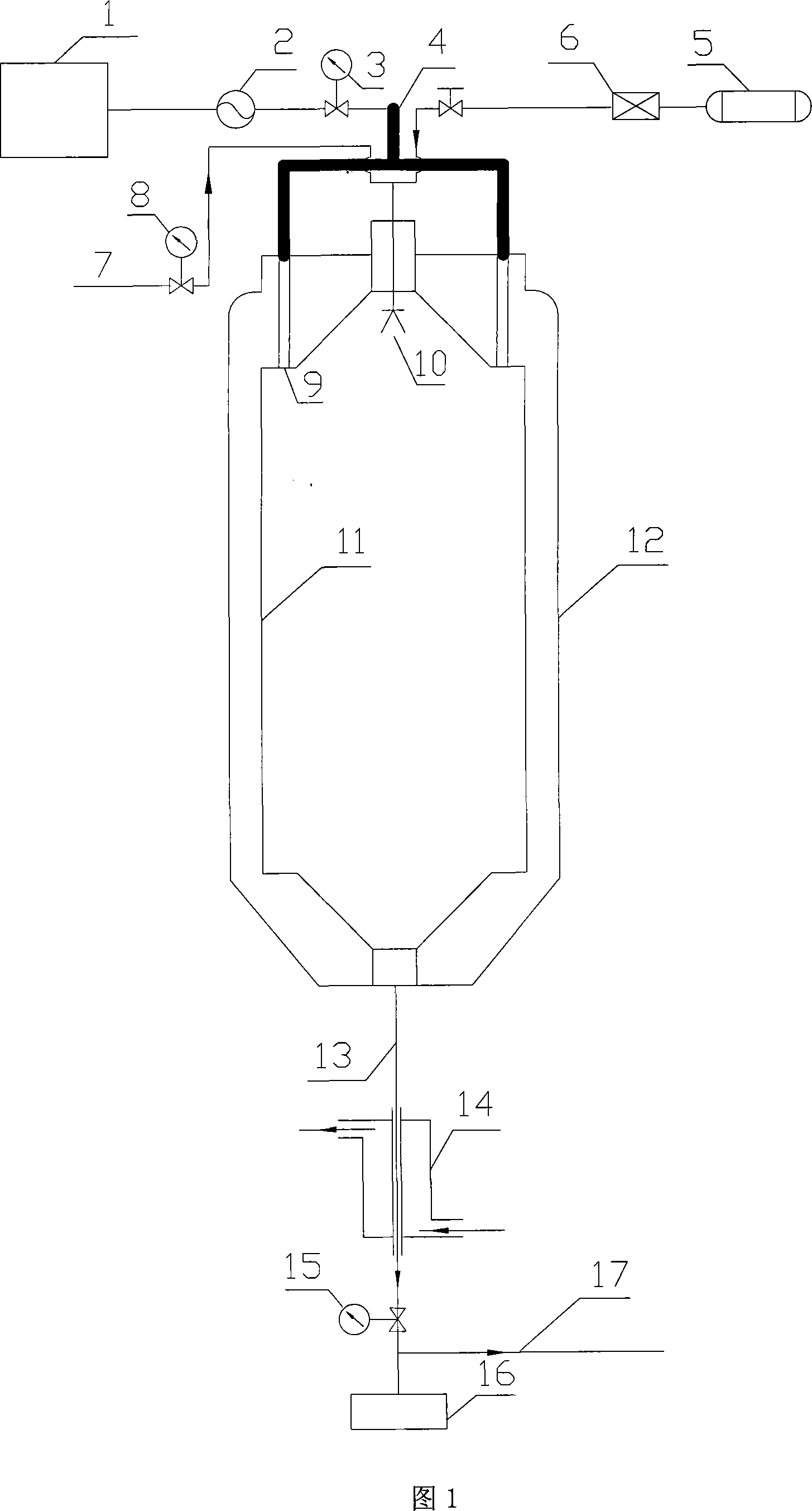

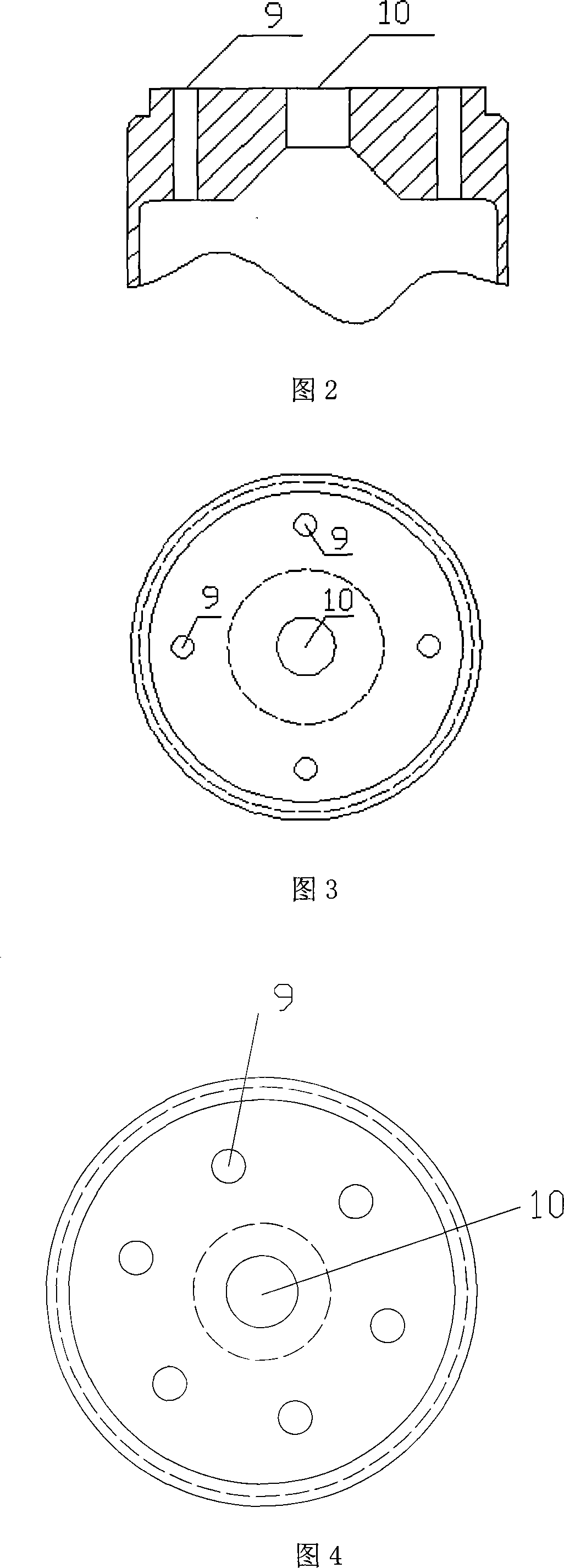

[0032] see figure 1 and figure 2 and image 3 As shown, in the gasification method provided by the present invention, after the bio-oil is preheated and heated up, under the aerodynamic action of the gasification agent, it enters the entrained bed reactor after being atomized through the atomizing nozzle, and the preheating temperature of the bio-oil is Lower than 80°C; the atomized bio-oil is partially oxidized, pyrolyzed and gasified in the entrained bed reactor to produce combustible gas, the resulting reaction product is condensed, and the residue is separated to obtain crude synthesis gas.

[0033] see figure 1 As shown, the entrained bed reactor 11 in the present invention is the core device, and a furnace shell 12 is arranged outside the reactor 11 . The bio-oil is preheated to 60-75° C. through the preheater 6, so that the viscosity of the bio-oil is reduced, which is beneficial to its atomized feed. An atomizing nozzle 10 is provided before the bio-oil enters the...

Embodiment 2

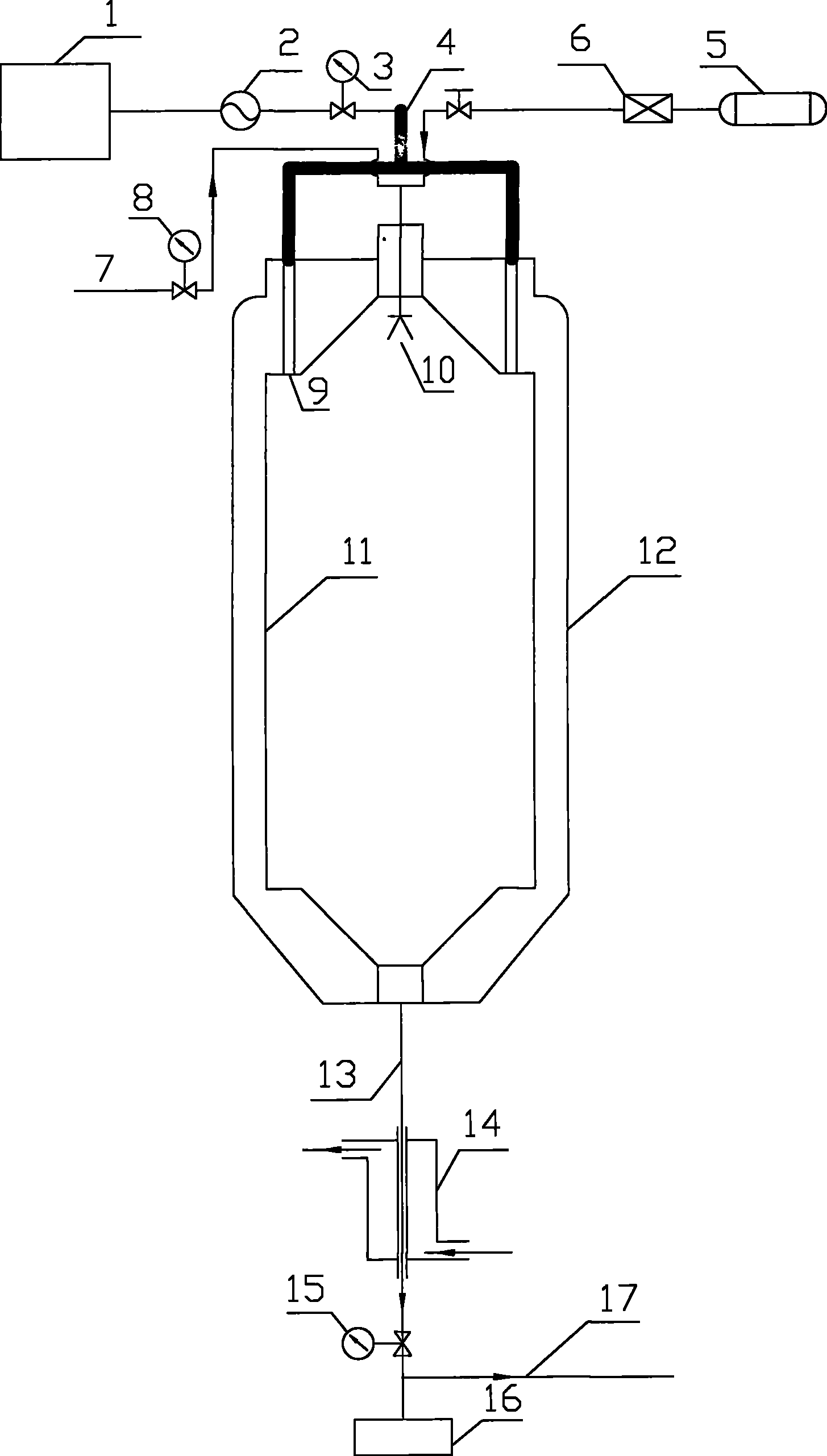

[0039] see Figure 4 As shown, in this embodiment, the superheated steam enters the entrained bed reactor 11 through the draft tube 4 and six distribution tubes separated by the draft tube, and the distribution tube is communicated with the water vapor input port 9. In this embodiment Adopt six distributing pipes in the example, therefore formed six water vapor inlets 9 on the entrained bed reactor 11, make it form the structure that takes nozzle 10 as the center of circle symmetrical distribution, like this water vapor inlet is more accurate on the horizontal distribution surface. Uniform distribution, can evenly input water vapor into the entrained bed reactor. Of course, at the relative position of the nozzle and the superheated steam inlet, the number of the steam inlets is not limited. When the cross-section at the inlet of the entrained bed reactor 11 is larger, eight or ten or more can be used. The water vapor input port 9 is to ensure that the water vapor can enter th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com