Integral treatment utilization method for sludge produced from water works

A waterworks, comprehensive treatment technology, applied in the direction of dehydration/drying/concentrated sludge treatment, sewage/sludge fertilizer, application, etc., can solve the problem of not being able to realize the sludge resource treatment well and deal with a large amount of sludge To achieve the effect of increasing air and soil humidity, increasing rainfall, and improving the ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

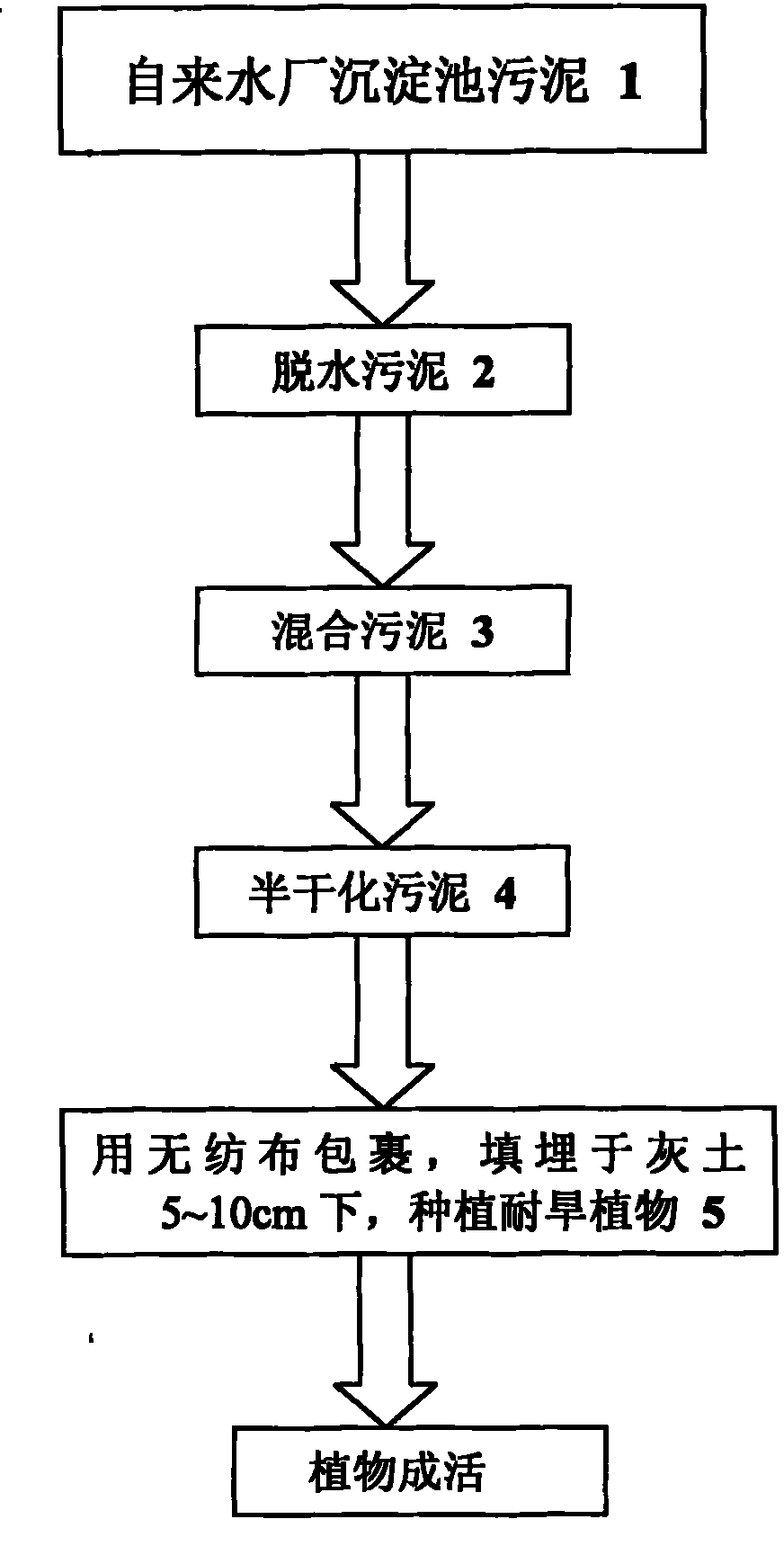

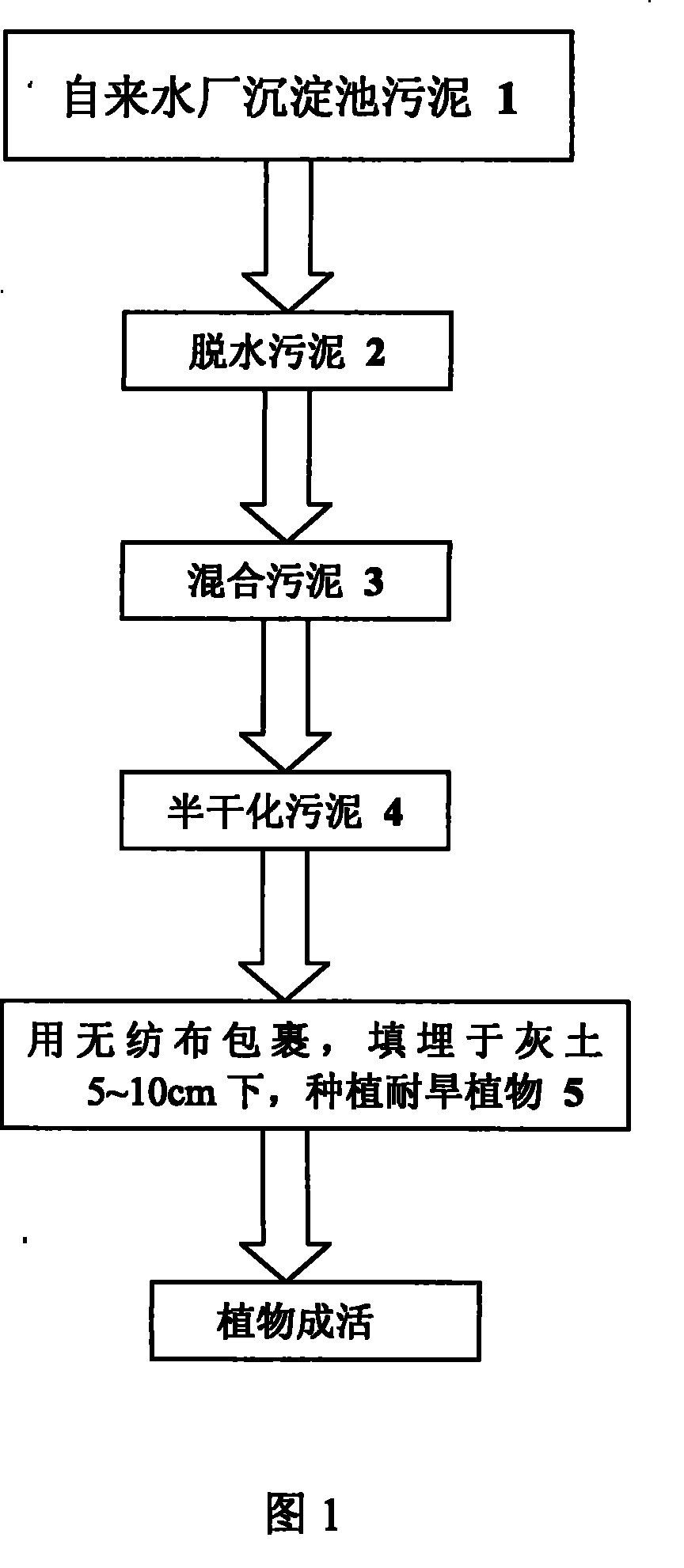

[0013] Embodiment 1, referring to Fig. 1, the method for comprehensive treatment and utilization of the sludge produced by the waterworks in this example comprises the following steps:

[0014] 1) The sludge used in this example comes from Tangqi Water Plant of Hangzhou Yuhang Water Supply Group Co., Ltd. The sludge produced by the waterworks is different from the sludge produced by the sewage treatment plant. The sludge discharge water is mainly composed of sedimentation tank or clarification tank sludge discharge and filter backwash wastewater, and its water volume generally accounts for about 3% of the total water production of the waterworks~ 7%. The sludge water from the waterworks contains a large amount of suspended matter, and its total solid content is generally between 0.1% and 2%, that is, the sludge moisture content is above 95%. The sludge with high water content has a large volume, which is not conducive to storage and transportation. According to experiments an...

Embodiment 2

[0021] Embodiment 2, please refer to Figure 1, the implementation steps of this example are as follows:

[0022] 1) The sludge is the sludge from the sedimentation tank of the waterworks, which is concentrated by gravity sedimentation for a certain period of time, and most of the void water is removed to obtain dewatered sludge.

[0023] 2) Add the additive fly ash whose dosage is 30% of the mass of the dewatered sludge to form mixed sludge.

[0024] 3) The mixed sludge is made into a strip-shaped pile with a width of 1.5 meters and a height of 1 meter, and the pile is retting for 15 days to allow it to fully ferment and form semi-dried sludge.

[0025] 4) Use a pulverizer to process the semi-dried sludge into sludge particles with a maximum particle size of no more than 8 cm, and then wrap the sludge particles with non-woven fabrics. The volume of each bag of sludge particles is controlled at about 0.5 cubic meters , and disperse and bury them 10 centimeters below the desert...

Embodiment 3

[0027] Embodiment 3, please refer to Figure 1, the implementation steps of this example are as follows:

[0028] 1) The sludge is the sludge from the sedimentation tank of the waterworks, which is concentrated by gravity sedimentation for a certain period of time, and most of the void water is removed to obtain dewatered sludge.

[0029] 2) Adding additive sawdust in an amount of 15% of the mass of the dewatered sludge to form mixed sludge.

[0030] 3) The mixed sludge is made into a strip-shaped pile with a width of 1.5 meters and a height of 1 meter, and the pile is retting for 11 days to allow it to fully ferment and form semi-dried sludge.

[0031] 4) Use a pulverizer to process the semi-dried sludge into sludge particles with a maximum particle size of no more than 8 cm, and then wrap the sludge particles with non-woven fabrics. The volume of each bag of sludge particles is controlled at about 0.28 cubic meters , and disperse and bury it 7 cm below the desert dust.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com