A double-light source laser annealing device and method

A technology of laser annealing and dual light sources, which is applied in the fields of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems that are difficult to meet the requirements of the 65nm node, and achieve the effect of reducing laser energy density and reducing thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

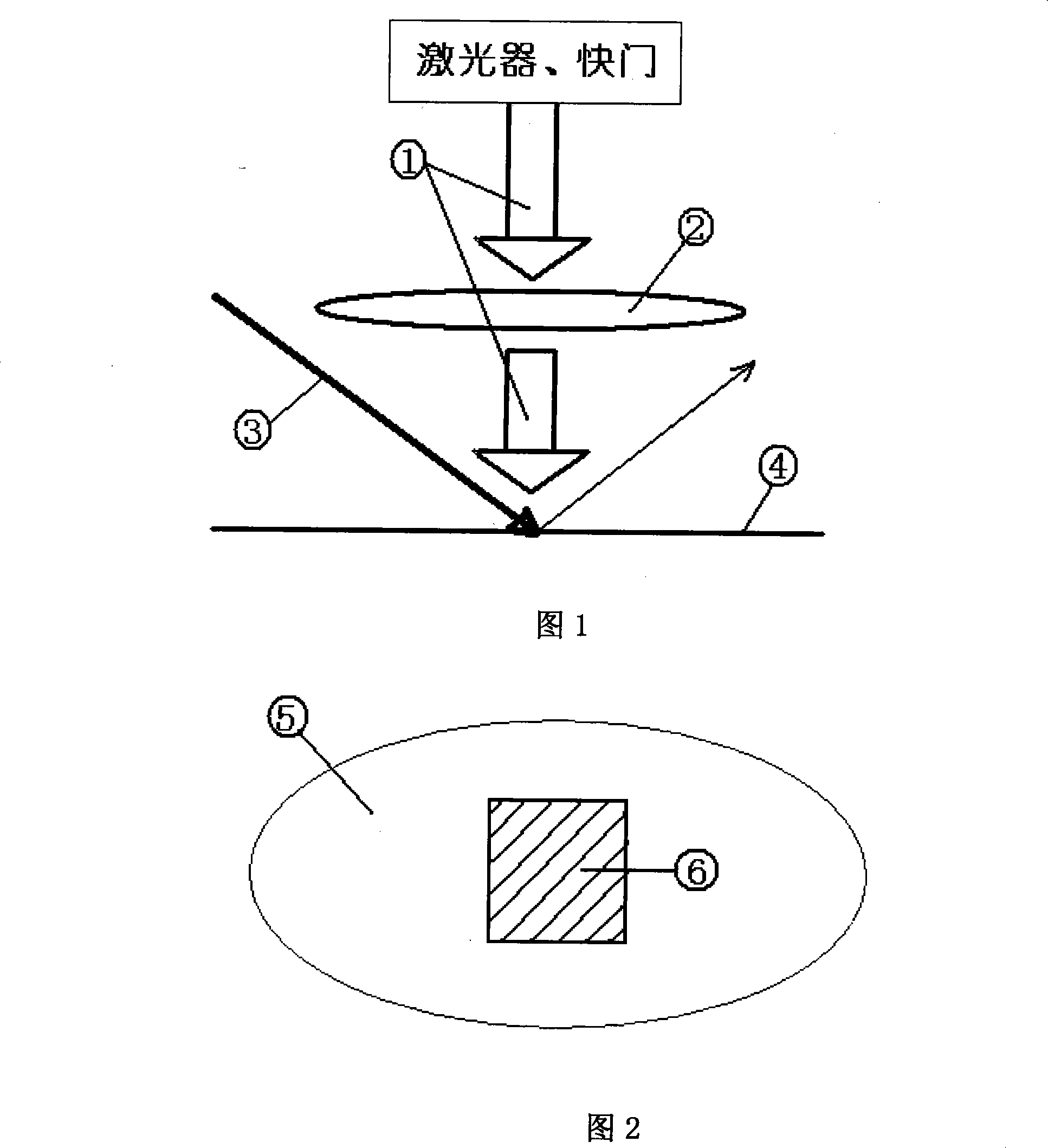

[0031] The invention provides a dual-light source laser annealing device and annealing method. The main structure of the laser annealing device with dual light sources is shown in Figure 1. In Fig. 1, the annealing laser source 1 is incident on the substrate wafer 4 above the wafer stage through the optical lens system 2 to anneal the substrate wafer; the substrate wafer 4 is mounted on the wafer stage Above, along with the film table in the vertical and horizontal directions, step by field, each time the position of the exposure field is moved; one exposure field is equal to the area of one or several chips, and the part of the edge of the exposure field with uneven light intensity Fall in the dicing groove on the edge of the chip; with the stepping of the wafer stage, the entire substrate wafer can be exposed field by field for laser annealing; another auxiliary heating light source of the device shown in Figure 1, auxiliary The heating beam 3 is incident obliquely to the surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com