A slip control digital intelligent speed regulation and system of motor without speed transducer

A speed sensorless, control digital technology, applied in the direction of slip frequency control, AC motor control, control system, etc., can solve the problems that affect the popularization and application of chopper series modulation system, pulse loss speed, and poor speed regulation performance. Achieve significant economic and social benefits, start smoothly, and respond quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

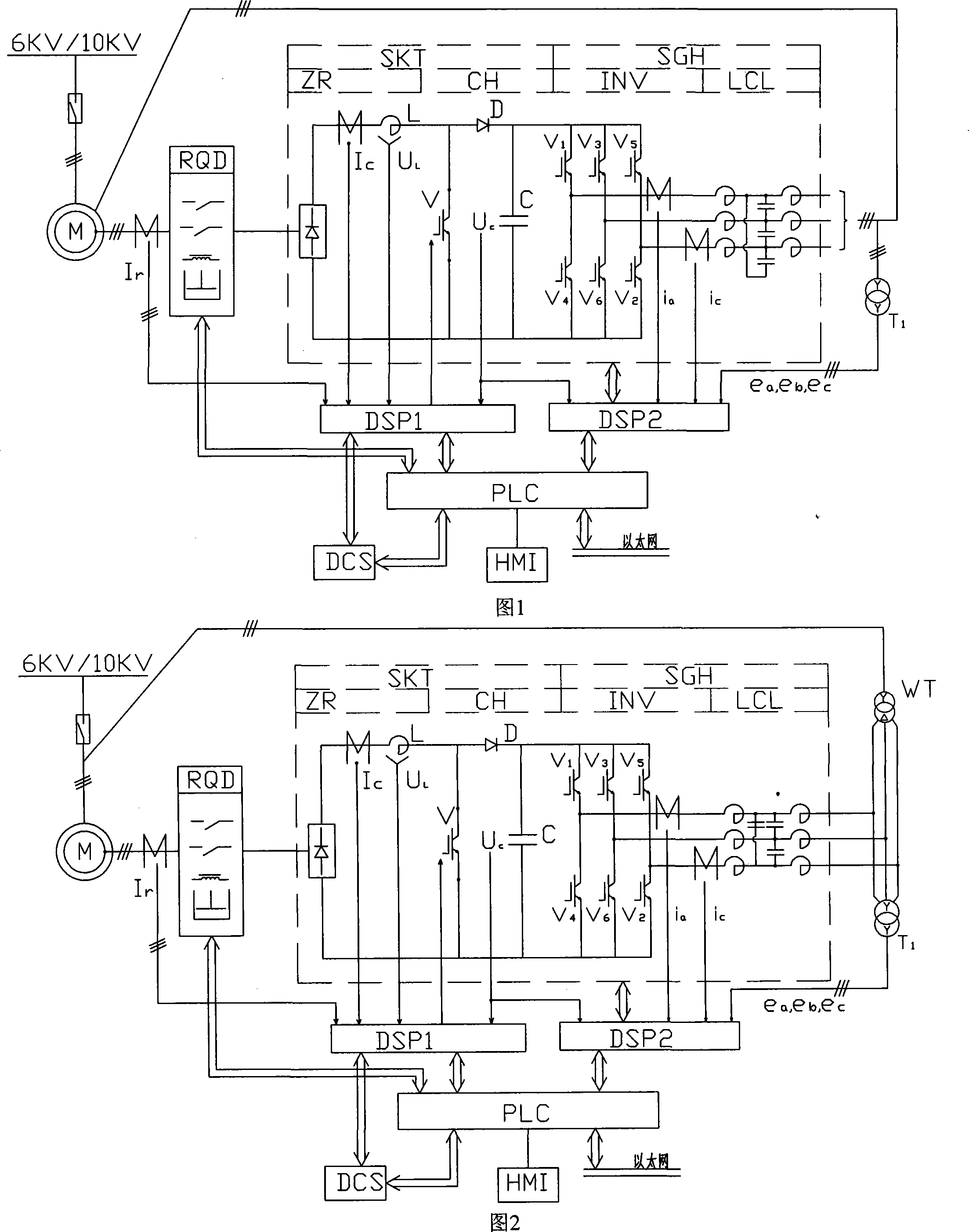

Embodiment 1

[0084] According to Fig. 1, the present invention is applied to a specific application example of an internally-fed winding asynchronous motor. In the picture, M is an internally-fed wound asynchronous motor. The stator winding is supplied by the 6kV or 10kV power grid through the high-voltage switchgear. The rotor winding is connected to the soft starter RQD. If the motor capacity is below 1000KW, frequency-sensitive rheostats are often used to start. , The large-capacity motor uses water resistance to start. The start of the motor is controlled by PLC. If there is no fault or alarm in the soft start circuit, a start signal is given on the touch screen. If there is a fault or alarm, a signal forbidden to close is given; if the slip rate controls the speed control of the SKT part and the rotation The differential power feedback SGH part has no faults and alarms. The touch screen will give an allowable speed control signal. If there is a fault or alarm, a prohibition of speed contr...

Embodiment 2

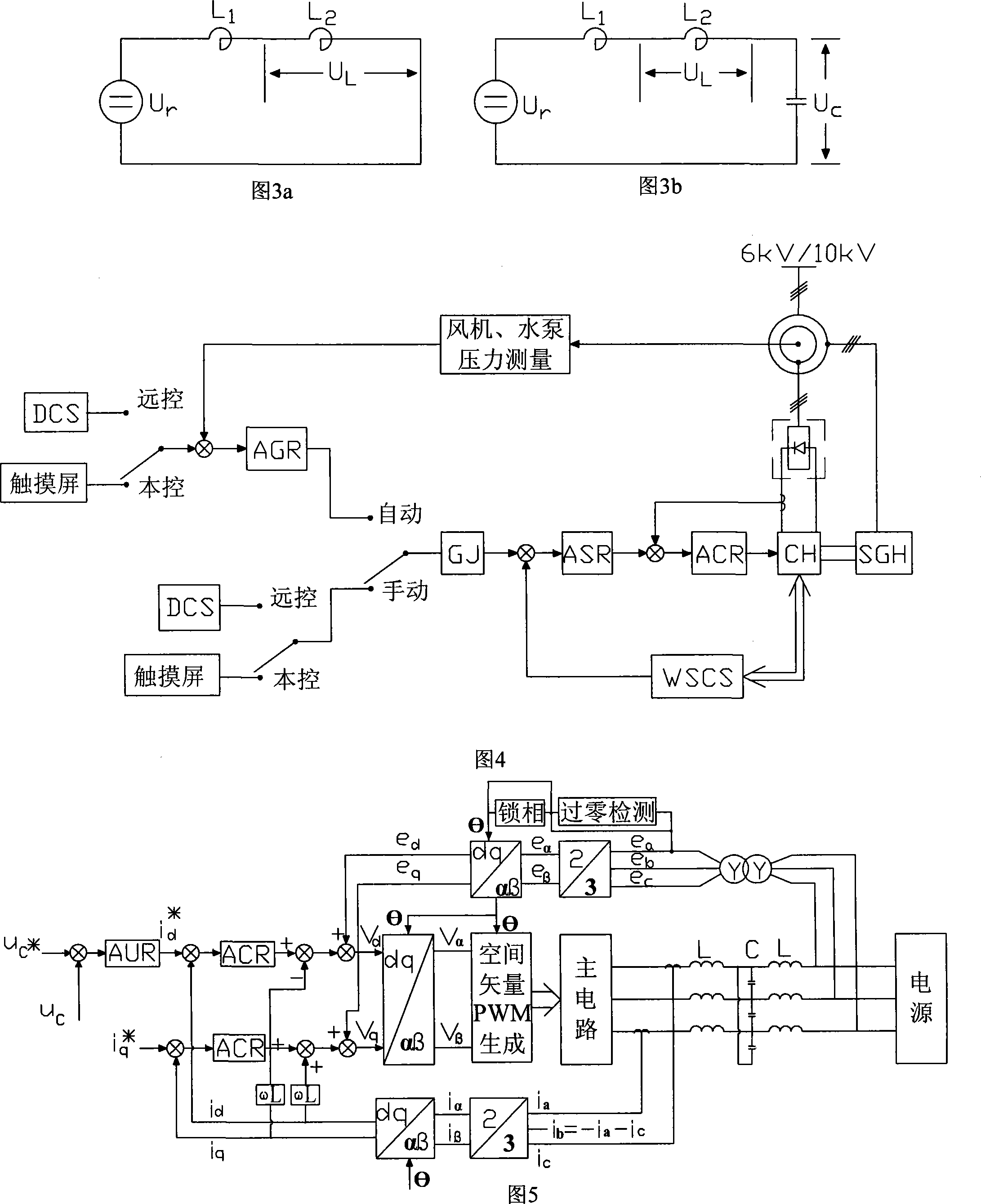

[0087] According to Figure 2, the present invention is applied to a specific application example of a common wound asynchronous motor. In the figure, M is an ordinary wound asynchronous motor without feedback winding. The rotor slip power must be fed back to the grid through the external-fed transformer WT. Therefore, the primary winding of the external-fed transformer is connected to the lower end of the high-voltage switch cabinet connected to the stator winding of the motor, and the secondary winding of the external-fed transformer is connected to the converter. The outlet end of the filter LCL of the differential power feedback circuit SGH. Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com