Copper aluminum/nickel plumbago composite powder material and production method

A composite powder, copper-aluminum-nickel technology, applied in the field of thermal spraying materials, can solve the problems of easily damaged abrasive parts, component deviation, high hardness of copper-aluminum/nickel graphite coating, etc., to achieve appropriate hardness, good manufacturability, and good grindability Effect of sealing properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The preparation method of copper-aluminum / nickel-graphite composite powder material of the present invention, main steps are as follows:

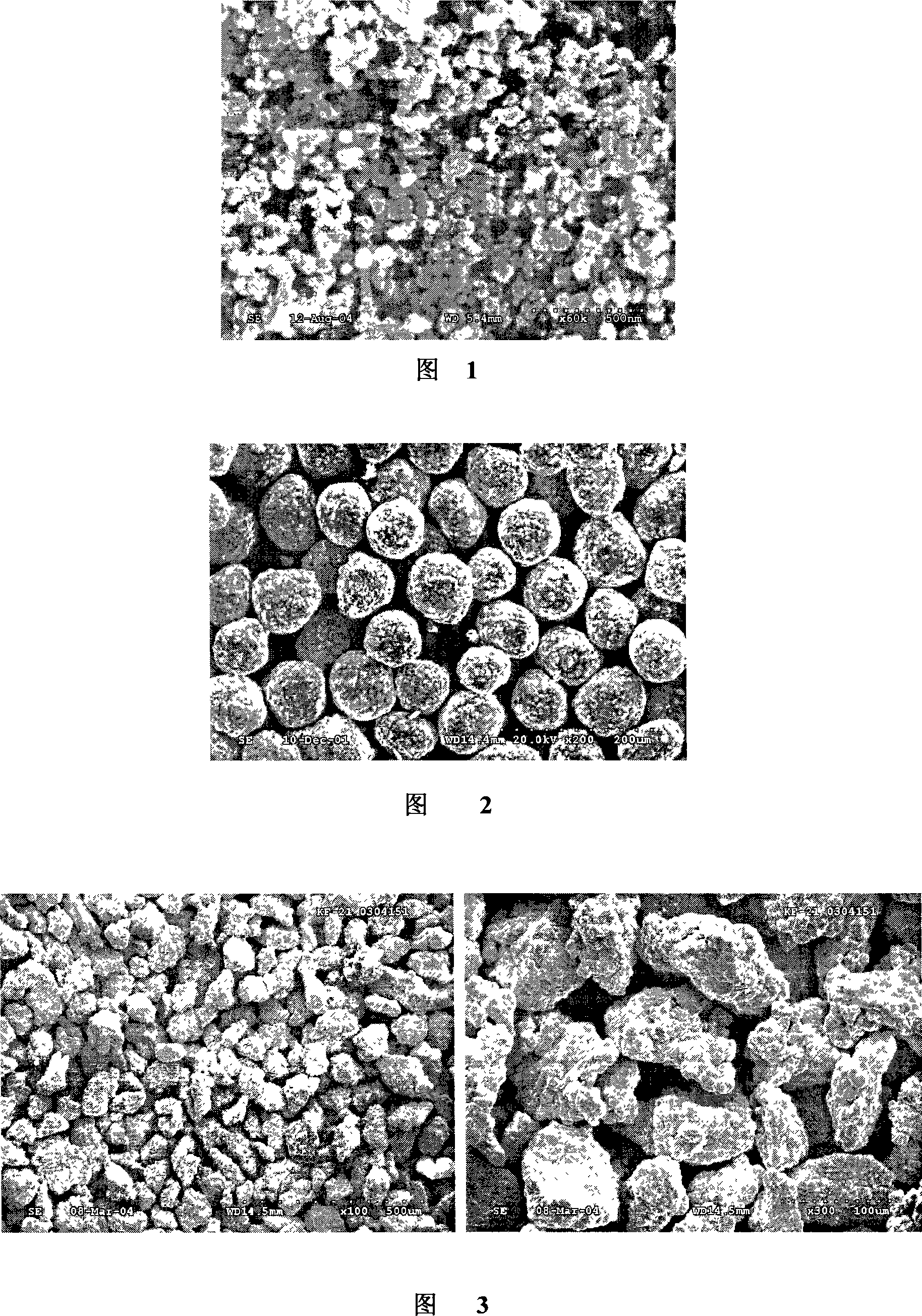

[0021] (1) Add Cu to the agglomeration equipment for stirring, add binder during stirring, after the binder and copper powder are fully wetted, then add Al in proportion to continue stirring evenly, finally dry the powder, and sieve to obtain copper Aluminum alloy powder intermediate material. The copper and aluminum elements can be added in the form of pure metal or alloy powder. The copper-aluminum composite powder intermediate material is prepared by mechanical mixing and coating or by atomization. The morphology of copper-aluminum composite powder is shown in Fig. 2.

[0022] (2) Add Ni and C elements in the form of nickel-graphite composite powder in proportion, and fully stir with the binder to prepare the nickel-graphite powder intermediate material. It is also possible to mix the Ni and C composite powder with the binder, ...

Embodiment 1

[0026] (1) Add 11kg of copper powder into the agglomeration equipment for stirring, and add a binder when stirring. Add 2.5kg of binder (polyurethane and acetone are prepared according to the ratio of 1:2), after the binder and copper powder are fully wetted, add 850g of ultra-fine aluminum powder (with a particle size of 1-30μm), then stir evenly, and dry the powder Then sieve. Prepared copper-aluminum composite powder.

[0027] (2) The copper-aluminum composite powder and 7kg nickel-coated graphite composite powder (chemical composition: Ni: 58.6%, C: 40.8%) were mechanically stirred and mixed to obtain a copper-aluminum-nickel-graphite composite powder.

Embodiment 2

[0029] (1) Add 9kg of copper powder to the agglomeration equipment for stirring, and add 2kg of binder (the binder is a polyvinyl alcohol solution with a concentration of 10%) when stirring. After the binder and the copper powder are fully wetted, add 1 kg of ultra-fine aluminum powder (with a particle size of 1.5 μm), then stir evenly, and then sieve the powder after it is dried.

[0030] (2) Fully mix about 11kg of nickel-graphite composite powder (Ni: 80%, C: 20%) with the above-mentioned 0.5kg binder, and then add 240g of ultra-fine aluminum powder (with a particle size range of 1 to 30 μm), Stir well, dry the powder and sieve to prepare Al-Ni-Graphite.

[0031] (3) Fully mixing aluminum / nickel graphite and copper-aluminum composite powder to prepare copper-aluminum-nickel-graphite composite powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com