Growth silicon based thin film and PECVD equipment for high-efficiency silicon based thin-film solar cell

A technology of solar cells and silicon-based thin films, applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of increasing the complexity of the operation process and prolonging the growth cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

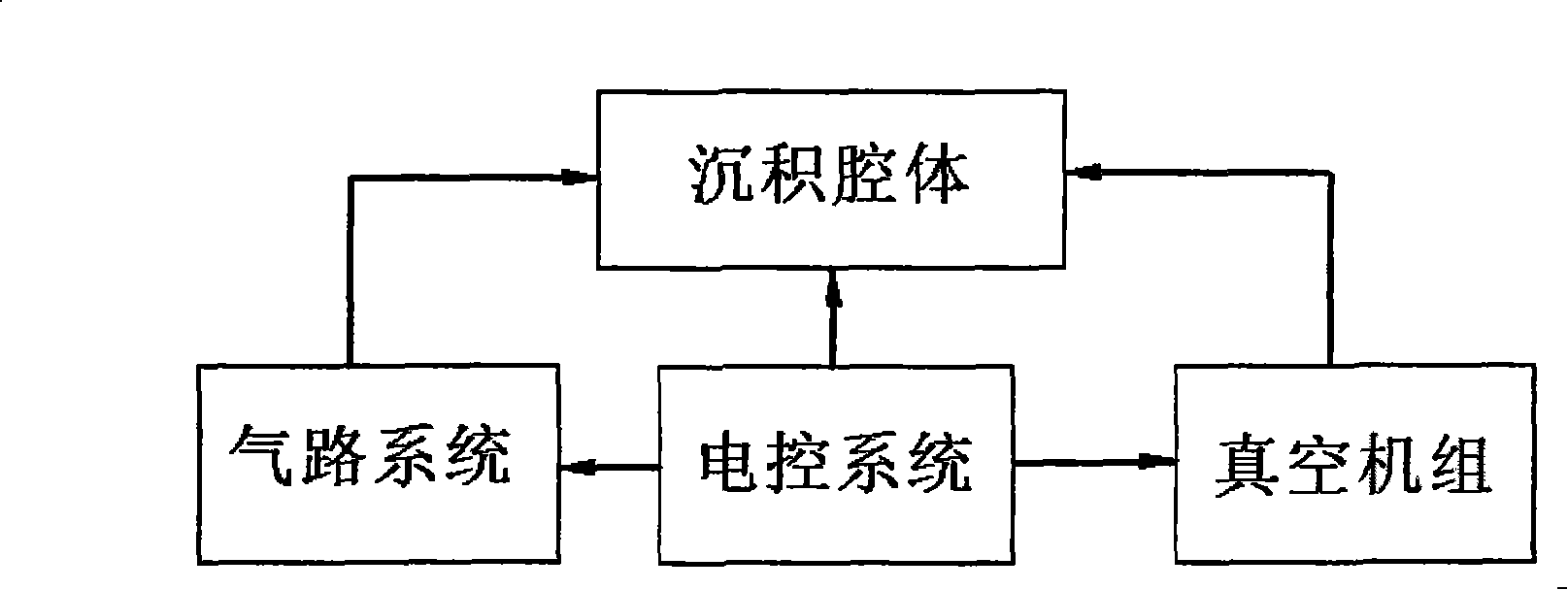

[0027] Such as figure 2 As shown, the present invention is composed of a deposition chamber, a gas path control system, an electric control system, and a vacuum unit. The electric control system controls the deposition chamber, the gas path control system, and the vacuum unit.

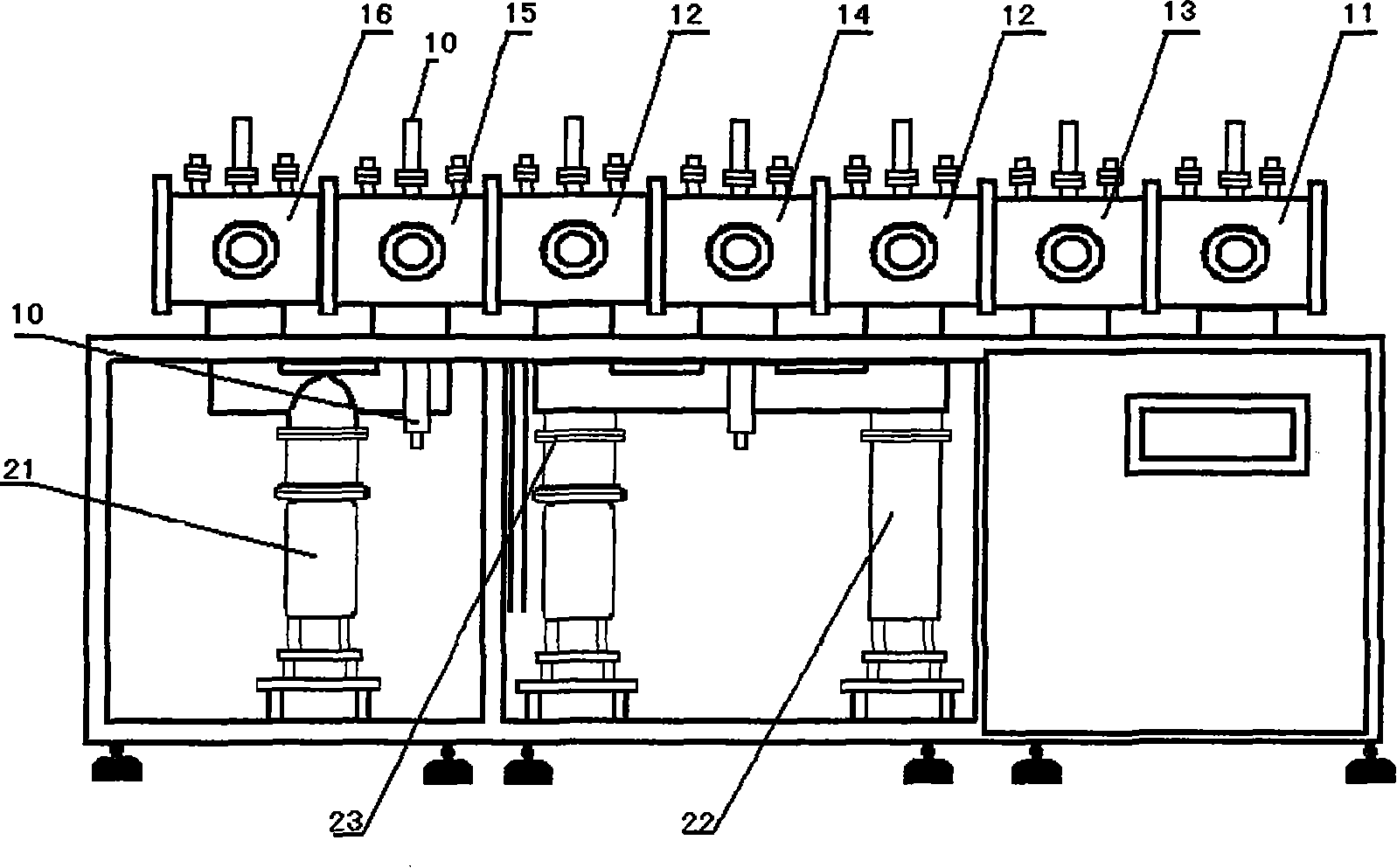

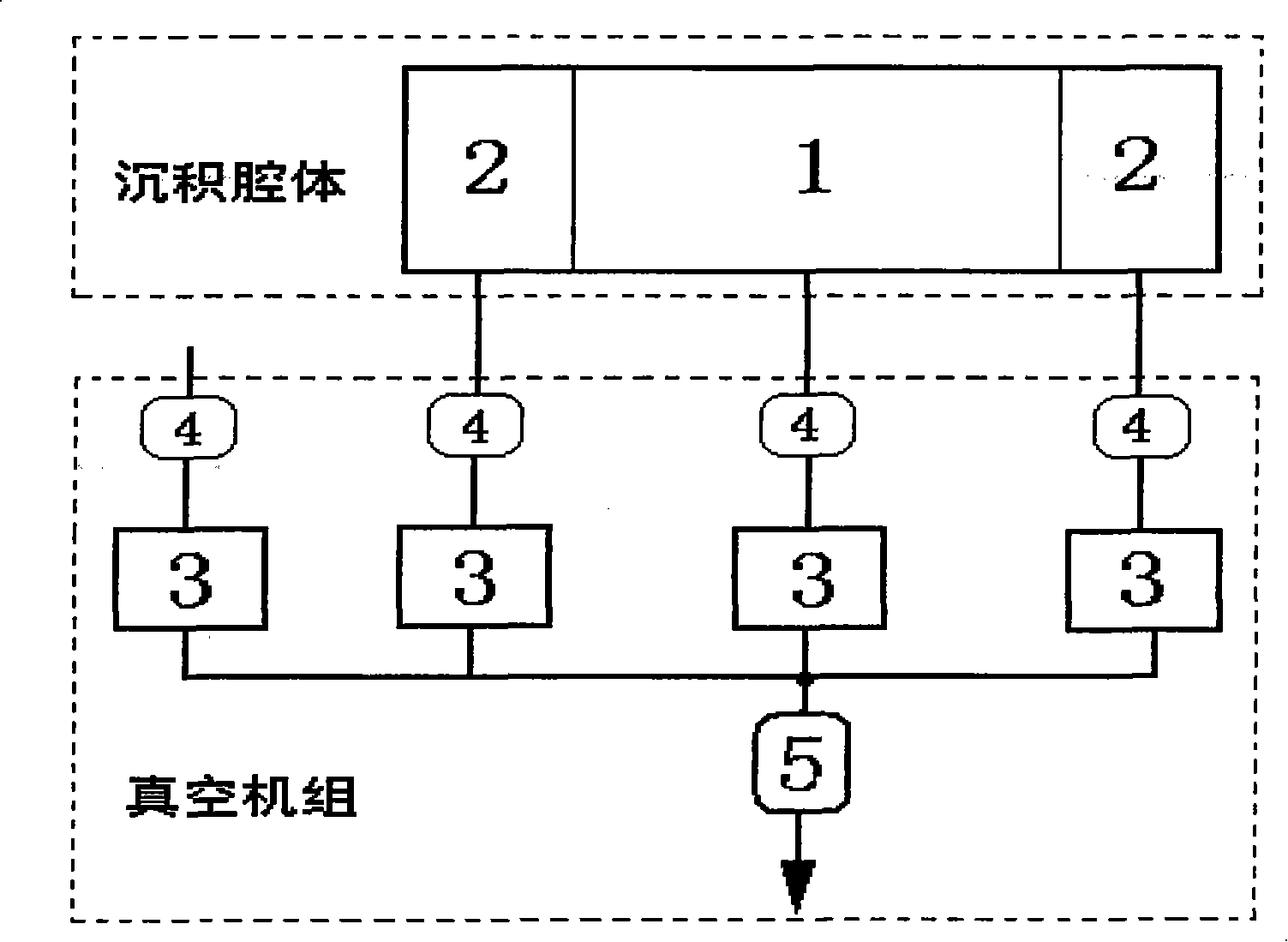

[0028] The connection between the deposition chamber and the vacuum unit is as follows: image 3 As shown; the condensation filter 4 is respectively connected with the growth chamber 1, the inlet and outlet chamber 2, the mechanical pump 3, and the exhaust gas pipeline. The mechanical pump 3 is connected with the exhaust gas treatment device 5 and the condensation filter 4 by a stainless steel bellows with a diameter of 50 mm. image 3 The leftmost mechanical pump in the middle is used for exhaust gas discharge. It is connected to the condensation filter 4 through a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com