Semi-free piston linear generator set

A technology for generator sets and generator stators, which is applied to electric components, engine components, machines/engines, etc., can solve the problems of system work shock, high force intensity of crank connecting rod mechanism, and complex control system, and achieve power output efficiency. High, the effect of solving the stability of the working condition and the simple control system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

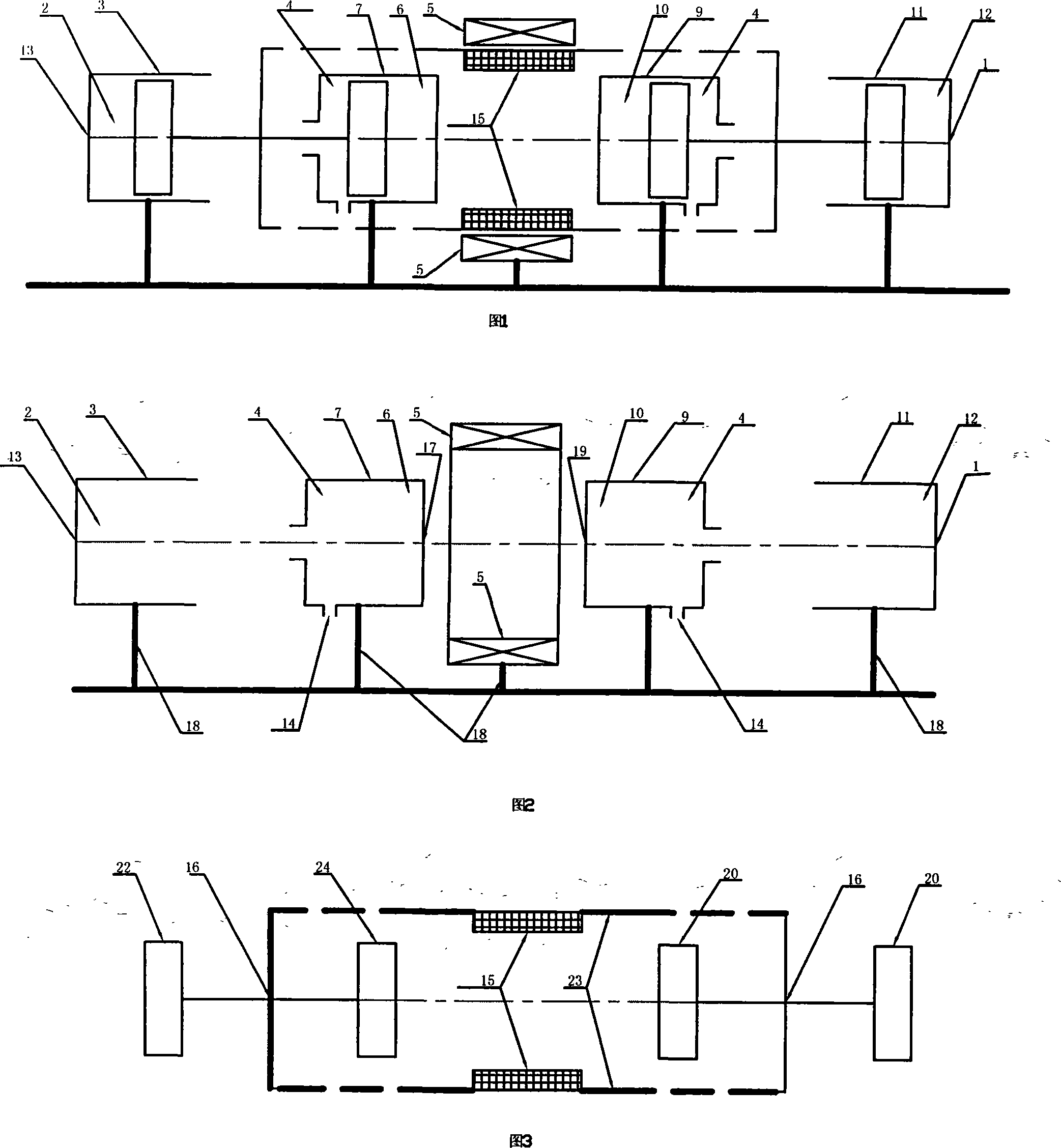

[0048] Examples of linked power generation units in the form of piston structures are as follows.

[0049] In FIG. 2 , the first cylinder 3 , the second cylinder 7 , the third cylinder 9 and the fourth cylinder 11 are axially and concentrically installed on the support member 18 . The first cylinder head 13 and the fourth cylinder head 1 face outward (respectively to the left and right as shown in FIG. 2 ), and the second cylinder head 17 and the third cylinder head 19 are opposite and close to the generator stator and winding 5 . The rear parts of the second cylinder 7 and the third cylinder 9 respectively have an air cushion chamber 4 and associated sealing and auxiliary air passages 14 . The generator stator and winding 5 are also installed on the support member 18, which is symmetrical with respect to the axis of the cylinder and located at the axial center of the whole device.

[0050] As shown in FIG. 3 , the first piston 22 and the second piston 24 are integrated throu...

Embodiment 2

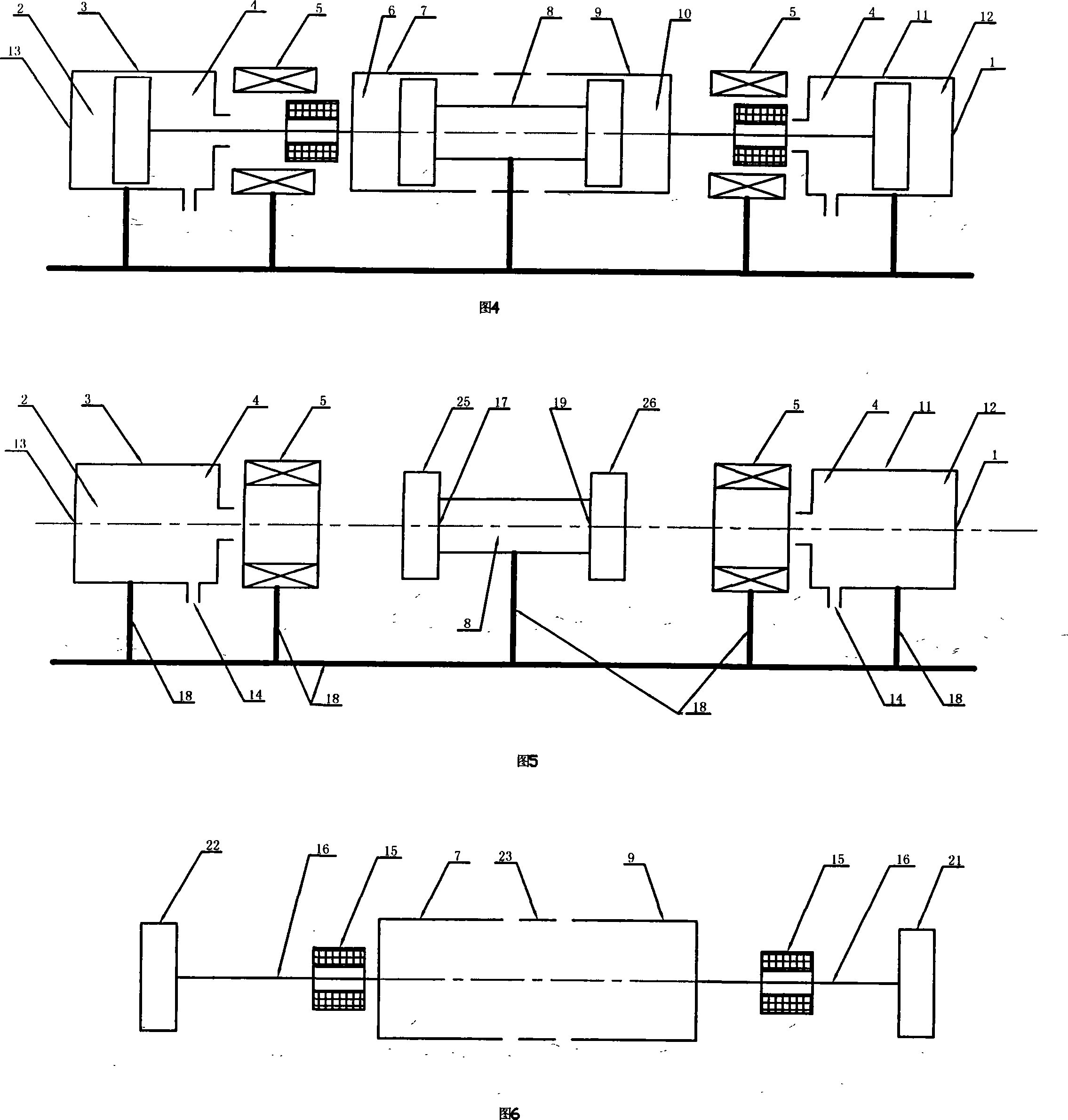

[0059] An example of a linkage generating unit in the form of a fixed plug structure is as follows.

[0060] As shown in FIG. 5 , the fixed plug 8 includes a second fixed plug 25 and a third fixed plug 26 , which are installed on the support member 18 between the two generator stators and the winding 5 . The fixed plug 8 is equipped with auxiliary components such as air passages, air valves, and ignition required by the second combustion chamber 6 and the third combustion chamber 10 . The tails of the first cylinder 3 and the fourth cylinder 11 respectively have a sealing structure associated with the auxiliary cylinder chamber 4 and an auxiliary air channel 14 . The generator stator and winding 5 are also installed on the support member 18, which is symmetrical with respect to the axis of the cylinder, divided into two parts and corresponding to the mover shaft 16 respectively.

[0061] As shown in accompanying drawing 6, the two generator movers 15 are respectively installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com