Automatic cleaning system for cleaning ball condenser

An automatic cleaning and cleaning ball technology, applied in the mechanical field, can solve the problems of increased power consumption, energy waste, time-consuming and labor-intensive shutdown cleaning, etc., to achieve the effects of increasing service life, good heat exchange effect, and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

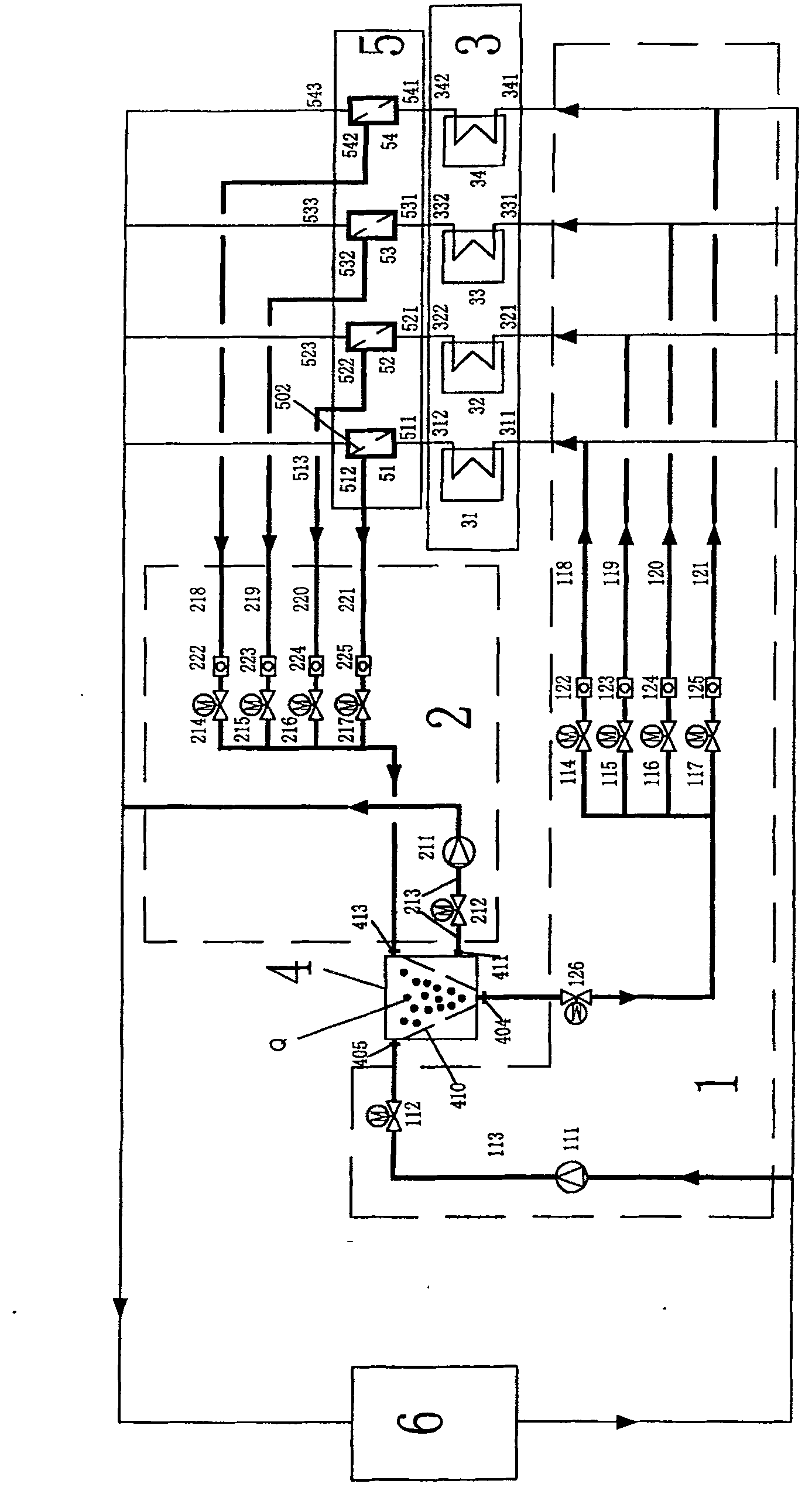

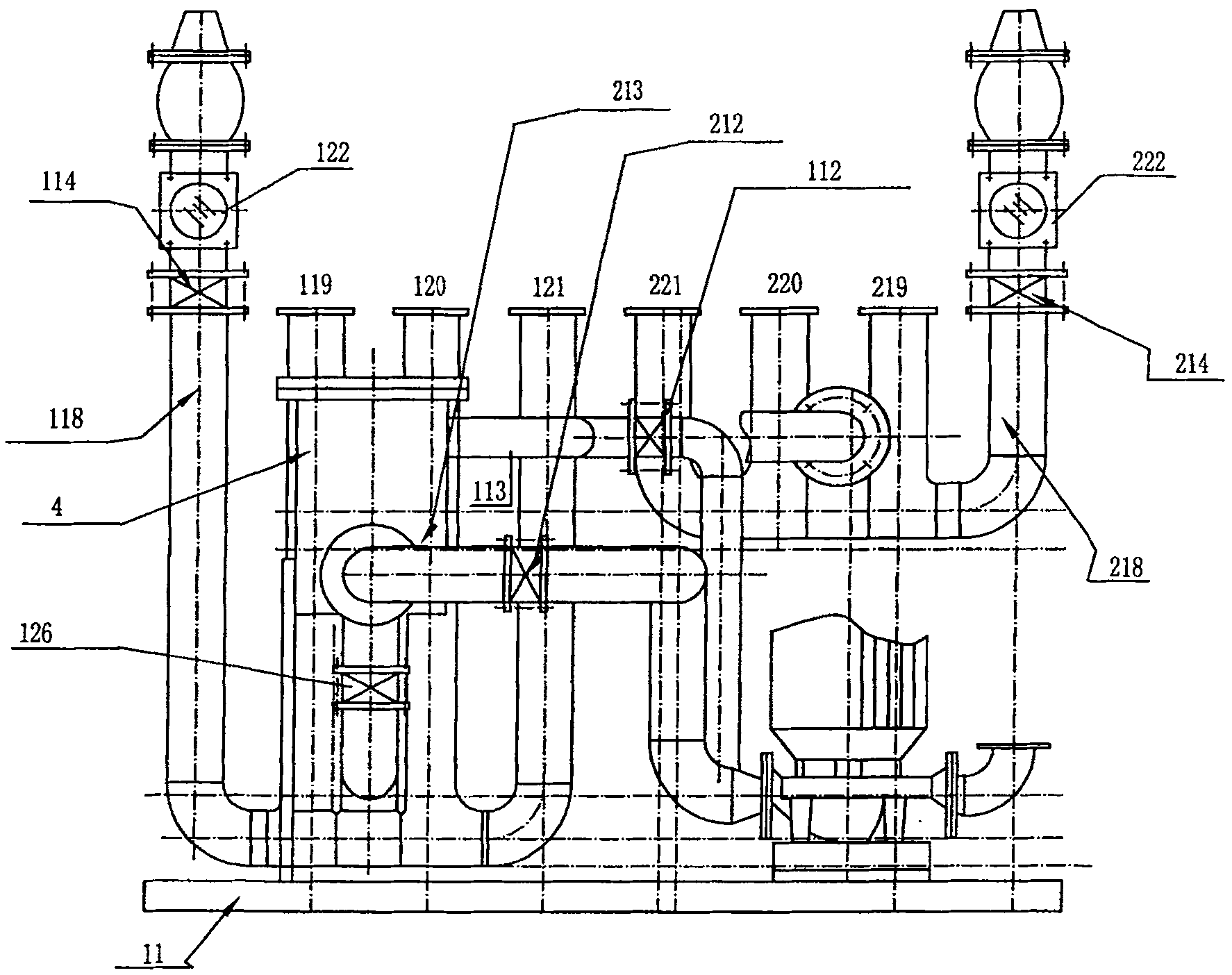

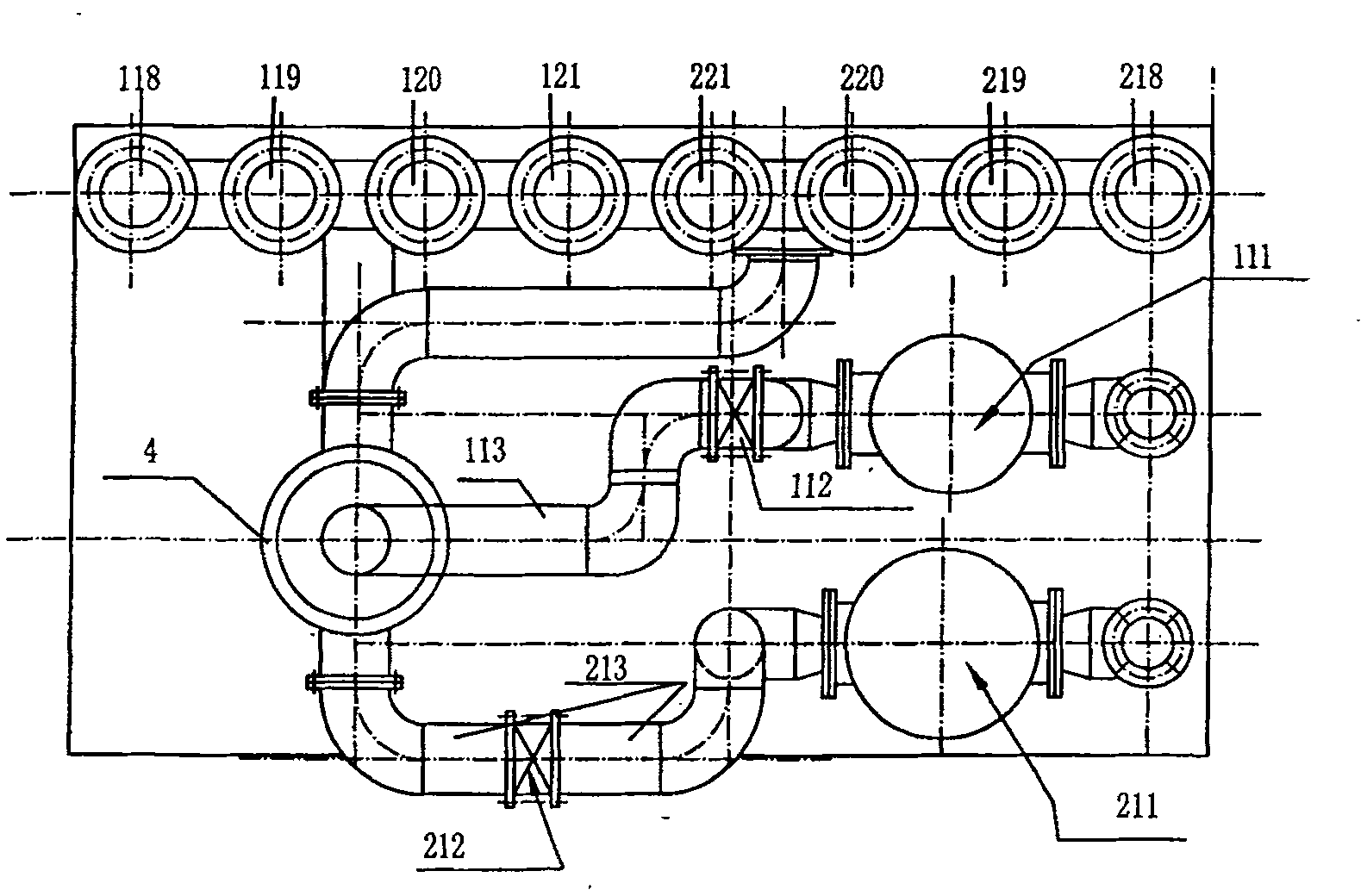

[0031] The present invention is composed of a ball injection system 1, a ball return system 2, a ball storage tank 4, a cleaning ball Q, a cleaning ball filter set 5, a cleaned condenser set 3, etc., and its installation and connection methods are as follows:

[0032] 1. Ball storage tank 4, cleaning ball filter group 5, water pump equipment, pipelines, etc. are fixed on the base 11, sight glasses 122-125 are fixed on the ball injection branch pipes 118-121, sight glasses 222-225 are fixed Placed on the ball return branch pipe 218-221, with the ball storage tank 4 as the center, the ball injection system 1, the condenser group 3, the cleaning ball filter group 5 and the ball returning system 2 are connected in sequence, and the cleaning ball Q moves along the condenser The inner wall of the group 3 copper pipe floats, moves and takes away the scale and attachments on the inner wall of the copper pipe, and the cooling water moving together with the cleaning ball Q returns to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com