Single slice battery essential resistance and voltage on-line testing system for fuel cell pile

A fuel cell stack and monolithic battery technology, applied in the direction of measuring resistance/reactance/impedance, signal transmission system, measuring electricity, etc., can solve problems such as limited functions and inability to perform online testing, and achieve high reliability and strong practicability , fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but these embodiments should not be construed as limiting the present invention.

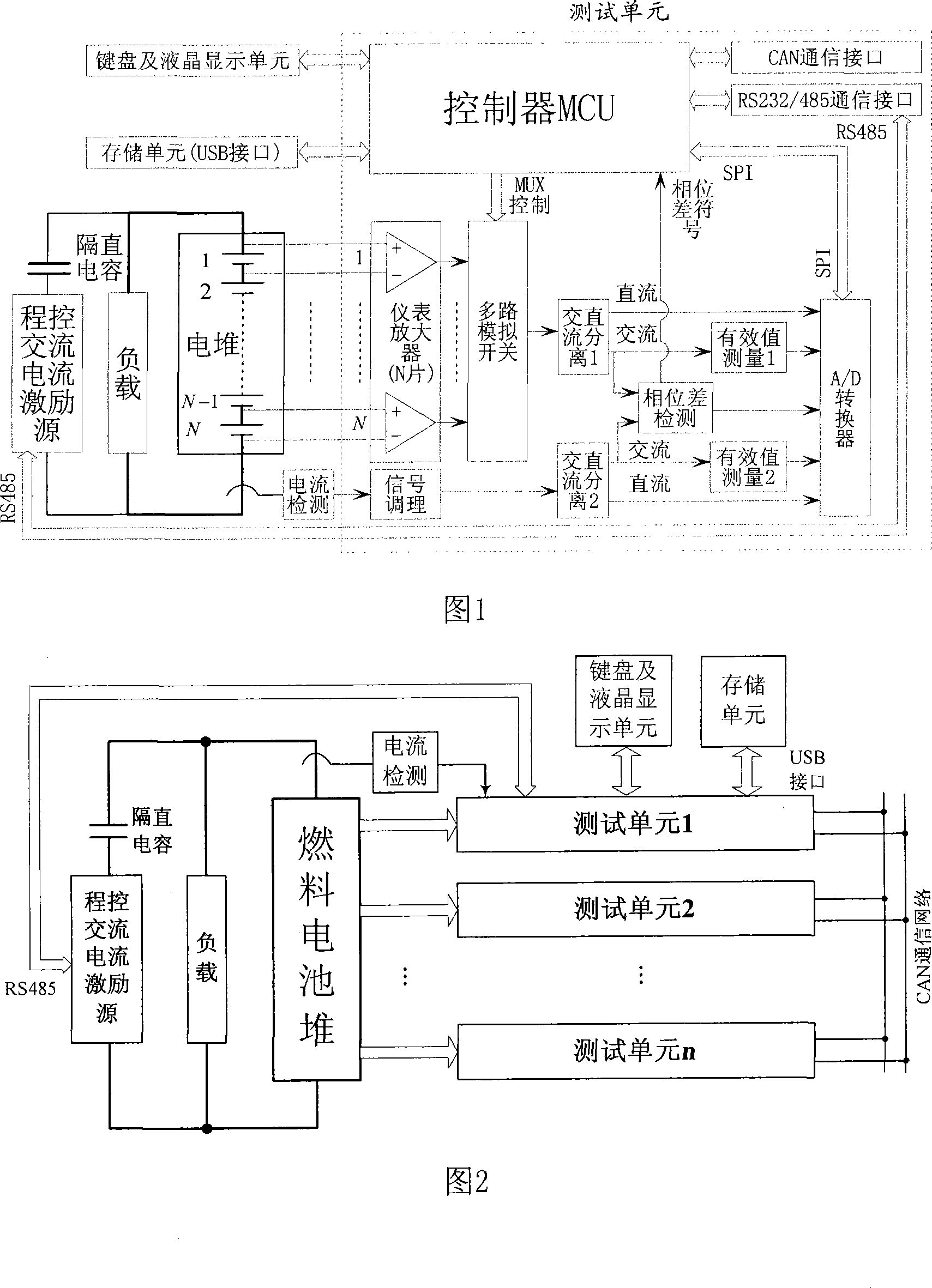

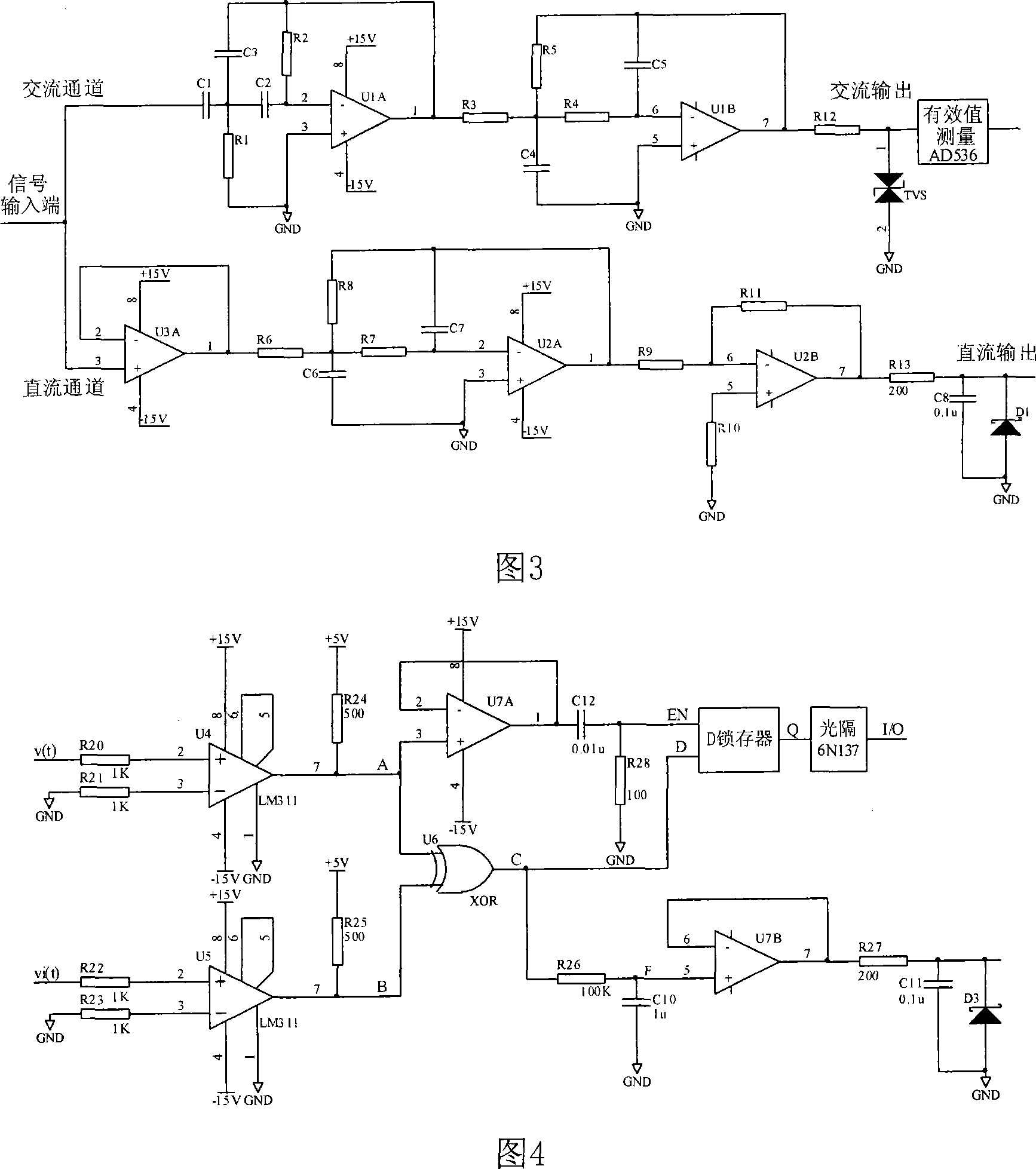

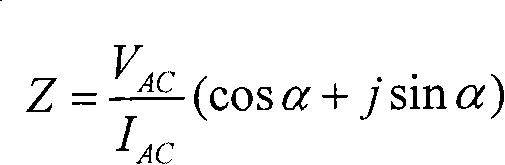

[0022] The invention includes a test unit, a program-controlled AC current excitation source and a DC blocking capacitor, a current detection module, a keyboard, a liquid crystal display unit, and a storage unit, wherein the test unit is composed of a controller MCU, an instrument amplifier, a multi-channel analog switch, a signal conditioning circuit, an AC Composed of DC separation circuit, phase difference detection circuit, effective value measurement circuit, A / D converter, RS232 / 485 communication interface and CAN (Control Local Area Network) communication interface (Figure 1), in which the program-controlled AC current excitation source is connected in series with a DC blocking capacitor Then it is connected in parallel with the fuel cell stack, so that a si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com