Foamable oil-in-water emulsion

An oil-in-water type, emulsion technology, which is applied in dairy products, food science, cream substitutes, etc., can solve the problems of undisclosed emulsions such as whipped cream, and achieve excellent mouth solubility, high whipping characteristics, and excellent flavor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

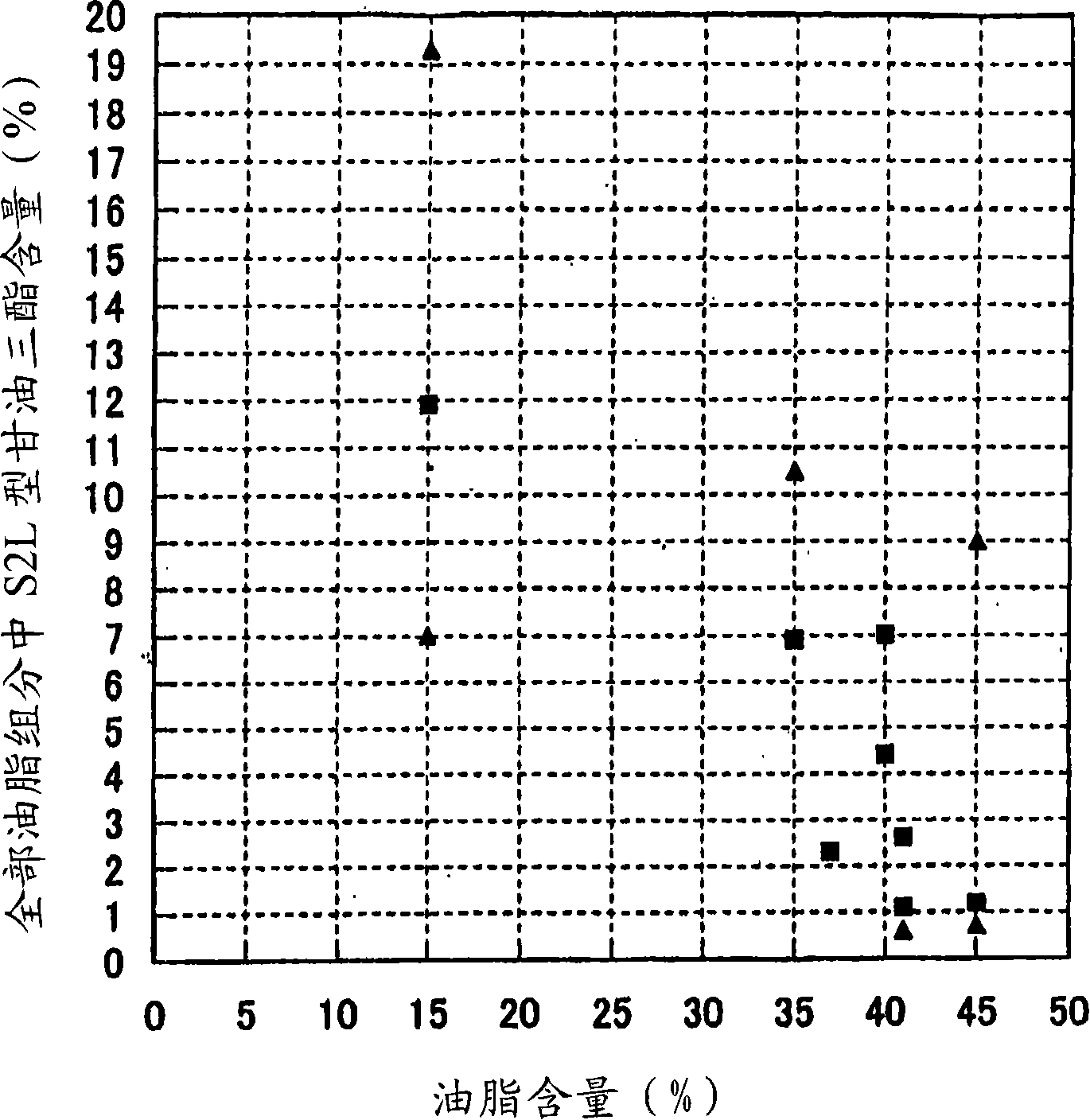

Image

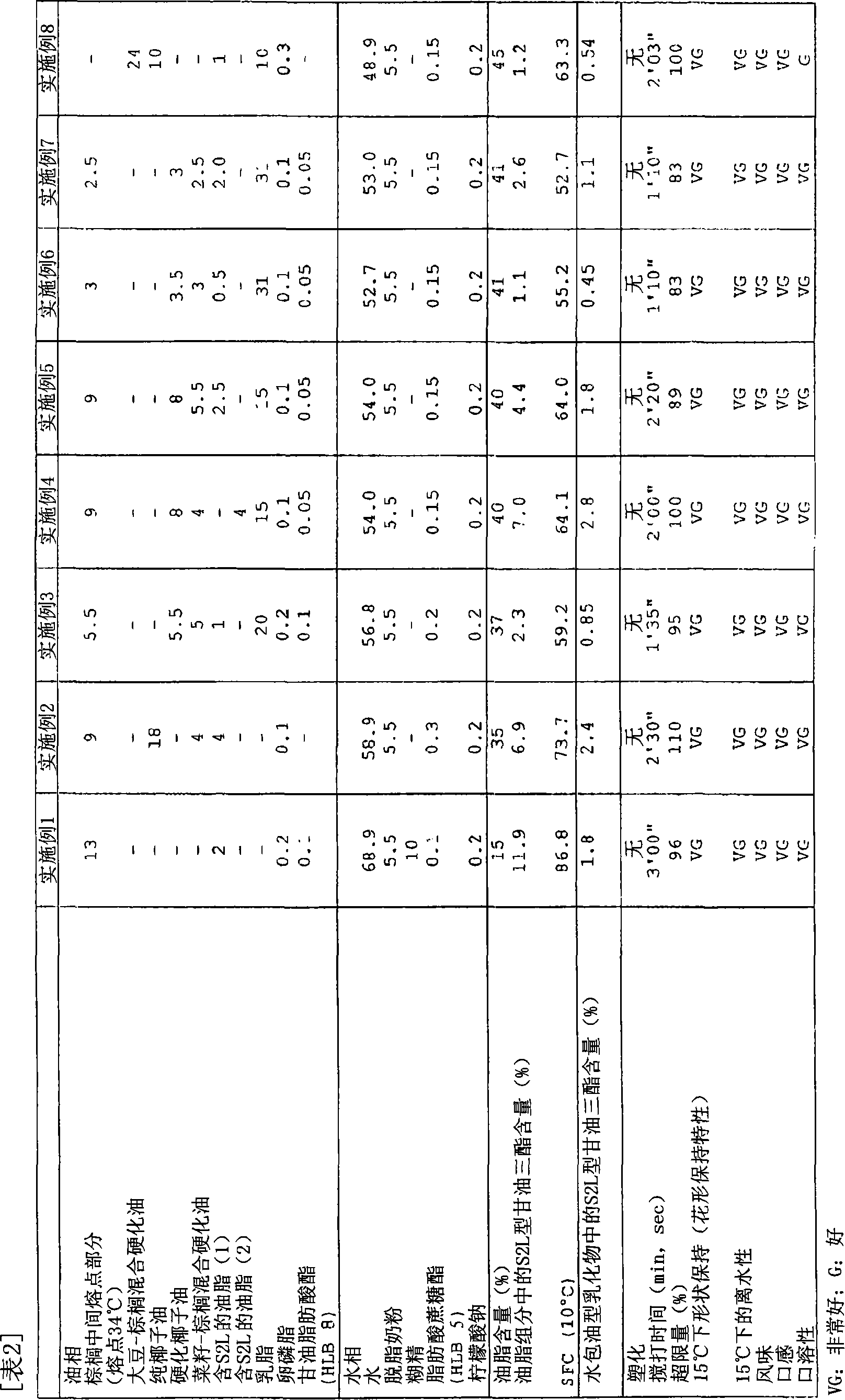

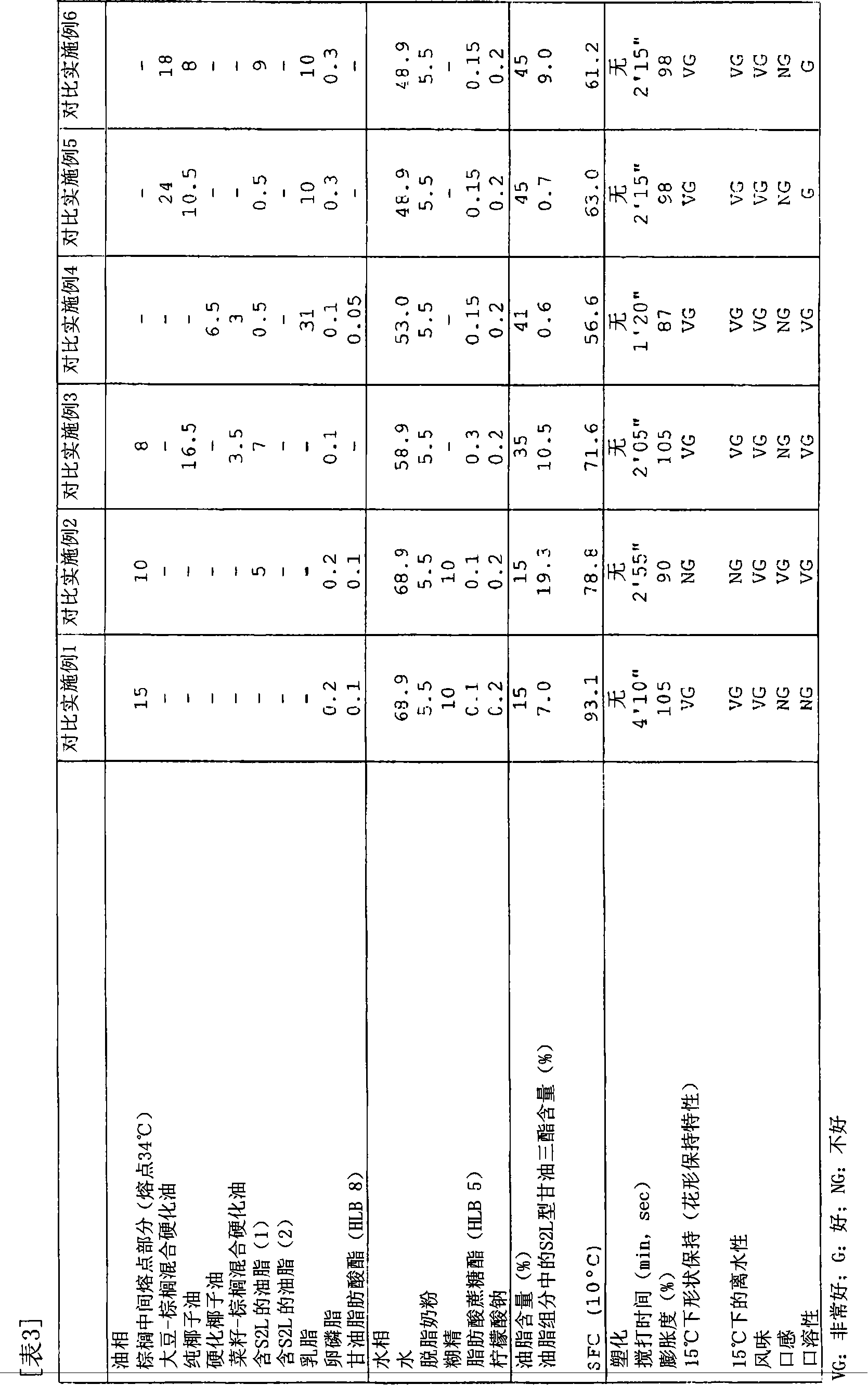

Examples

Embodiment

[0038] The present invention will be explained in detail by examples, but the spirit of the present invention is not limited to the following examples. In the examples, "%" and "part" are by weight. In particular, it goes without saying that the order of addition of additives, the order of emulsification such as adding an oil phase to a water phase or adding a water phase to an oil phase are not limited to the following examples. The results were evaluated by the following methods.

[0039] [A] Plasticization test of oil-in-water emulsion (stability of oil-in-water emulsion)

[0040] Plasticization test: put 50g of oil-in-water emulsion in a 100mL beaker, keep it warm at 20°C for 2h, and then shake it with a table shaker for 5min. Afterwards, it is possible to check whether plasticization of the oil-in-water emulsion occurs.

[0041] [B] Evaluation method of a product obtained by whipping an oil-in-water emulsion.

[0042] (1) Whipping time: the mixture of 1kg oil-in-water...

experiment example 1

[0046] Experimental example 1: Preparation of oil containing S2L (1)

[0047] A mixture of 20 parts of safflower oil and 80 parts of stearic acid was transesterified with a lipase specific for 1 and 3 positions, and then the ethyl ester part was removed by distillation to obtain S2L-containing oil (1).

experiment example 2

[0048] Experimental example 2: Preparation of oil containing S2L (2)

[0049] The mixture of cottonseed oil: acetone = 20:80 was melted, stirred and cooled to -10°C, and kept for 30 minutes to precipitate crystals. After that, the mixture was filtered under reduced pressure to separate into a crystal portion and a liquid portion.

[0050] The acetone in the resulting crystal portion was removed by conventional methods, and then this portion was decolorized and deodorized by conventional methods to obtain S2L-containing oil (2).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com