Method of removing siloxane from combustible gas, application and system thereof

A siloxane and gas technology, which is applied in the field of combustible gas impurity removal, can solve problems such as the influence of gas equipment, and achieve the effects of quick effect, simple system and low investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for removing siloxane in combustible gas, its specific steps are as follows:

[0027] First, the combustible gas containing siloxane (such as landfill gas, biogas generated in sewage or biogas generated from sludge) is sent into the compressor for compression, and the pressure is increased to 10kPa ~ 1.6MPa to remove liquid water and granular impurities; this is because most of the gaseous impurities in the combustible gas will become liquid and granular under high pressure, so pressurization is the first step to remove impurities;

[0028] Then, send the compressed combustible gas into the pre-cooling heat exchanger to cool the combustible gas to 0-5°C to further remove moisture and liquid impurities in the combustible gas; after the gas is cooled, a large amount of moisture and After the liquid impurities are condensed, they can be discharged from the sewage outlet on the pre-cooling heat exchanger;

[0029] Thirdly, the above-mentioned cooled combustible ga...

Embodiment 2

[0031] The above method for removing siloxane in combustible gas is used to remove heavy carbon hydrocarbons in petroleum associated gas. Among them, the removal rate of heavy carbon hydrocarbons is 85%, while that of siloxane is 90%.

Embodiment 3

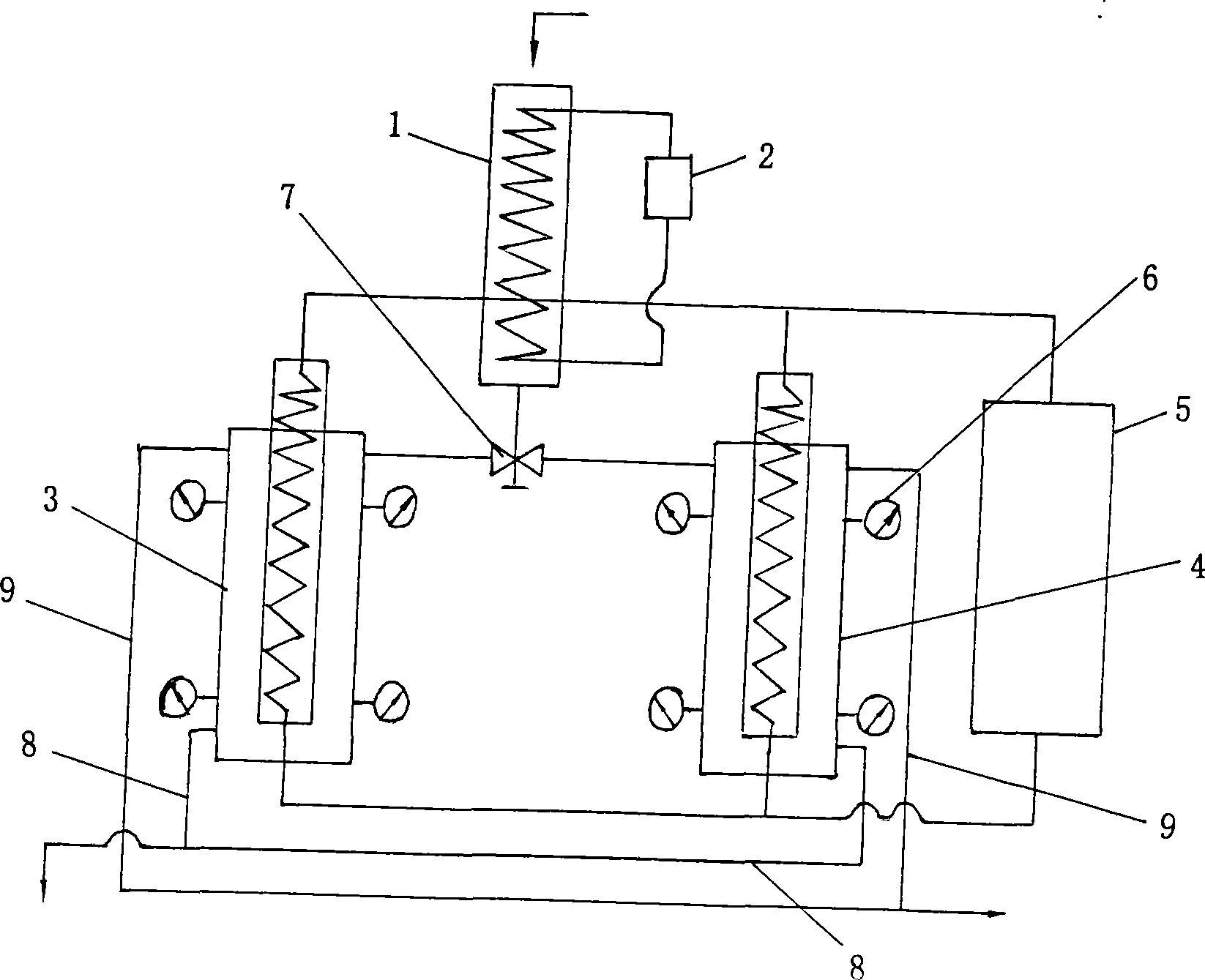

[0033] As shown in Figure 1.

[0034] A system for removing siloxane impurities in combustible gas, which consists of a pre-cooling heat exchanger 1, a refrigeration compressor 2 for pre-cooling, heat exchangers 3, 4, and a refrigeration compressor 5, and the pre-cooling heat exchanger 1 and Pre-cooling is connected with refrigeration compressor 2, and pre-cooling heat exchanger 1 is connected with gas inlet, outlet and liquid impurity discharge port (not shown in the figure), heat exchanger 3, 4 and refrigeration compressor 5 are connected in parallel, pre-cooling exchanging The air inlet of the heater 1 is connected with the combustible gas source (which can be landfill gas, sewage biogas, sludge biogas or petroleum-associated gas, etc.), and its gas outlet is respectively connected to the installed heat exchangers 3 and 4 through the valve 7. The air inlets on the gas tanks are connected, and the gas tanks installed with heat exchangers 3 and 4 are respectively connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com