Method and device for separating gold slice and solid fragment

A technology of gold and flakes, applied in the field of separating gold flakes and solid fragments, can solve the problems of serious pollution of aqua regia, highly toxic cyanide solution, complicated process, etc., and achieve the effect of fast recovery, simple equipment and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

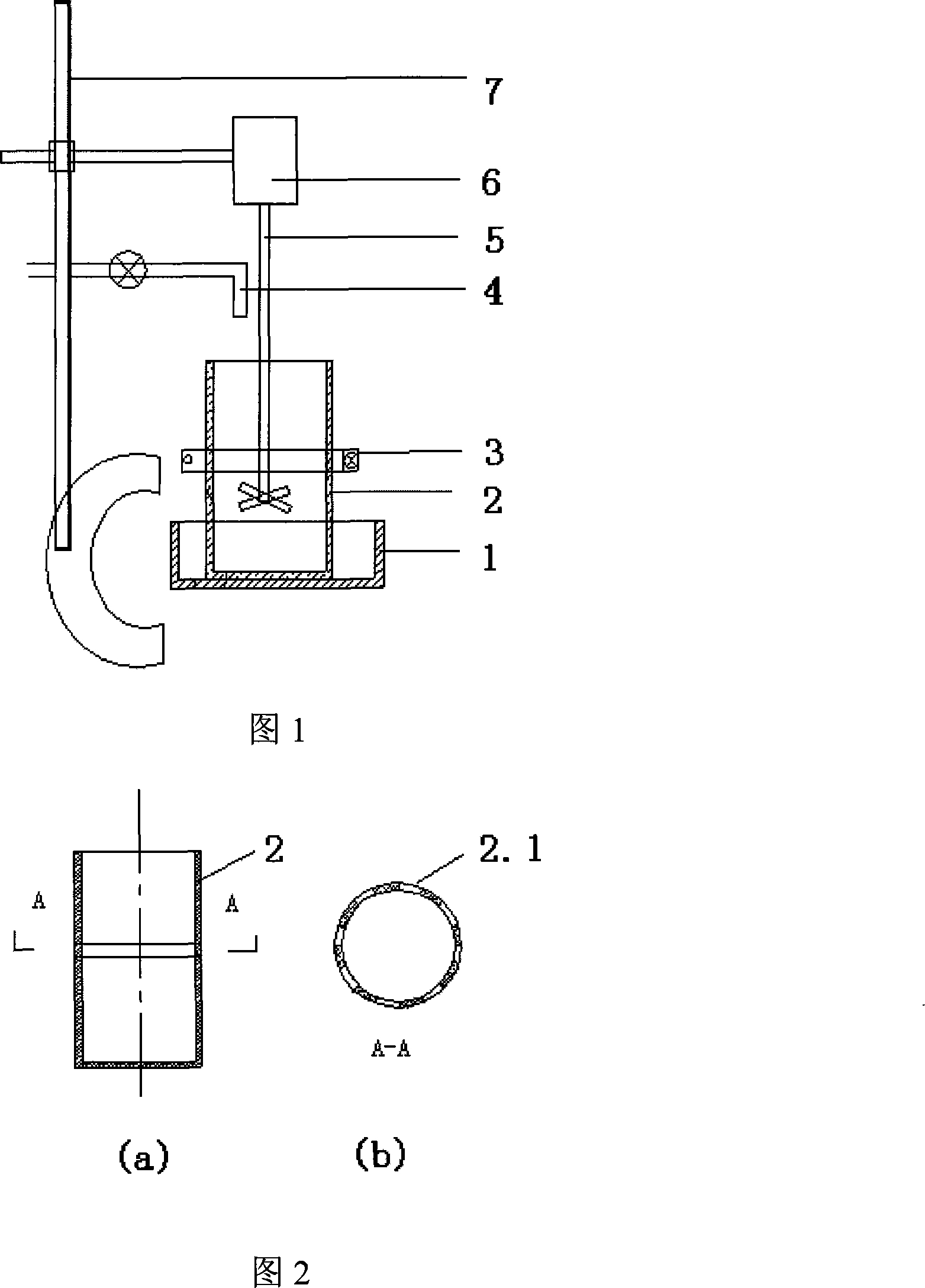

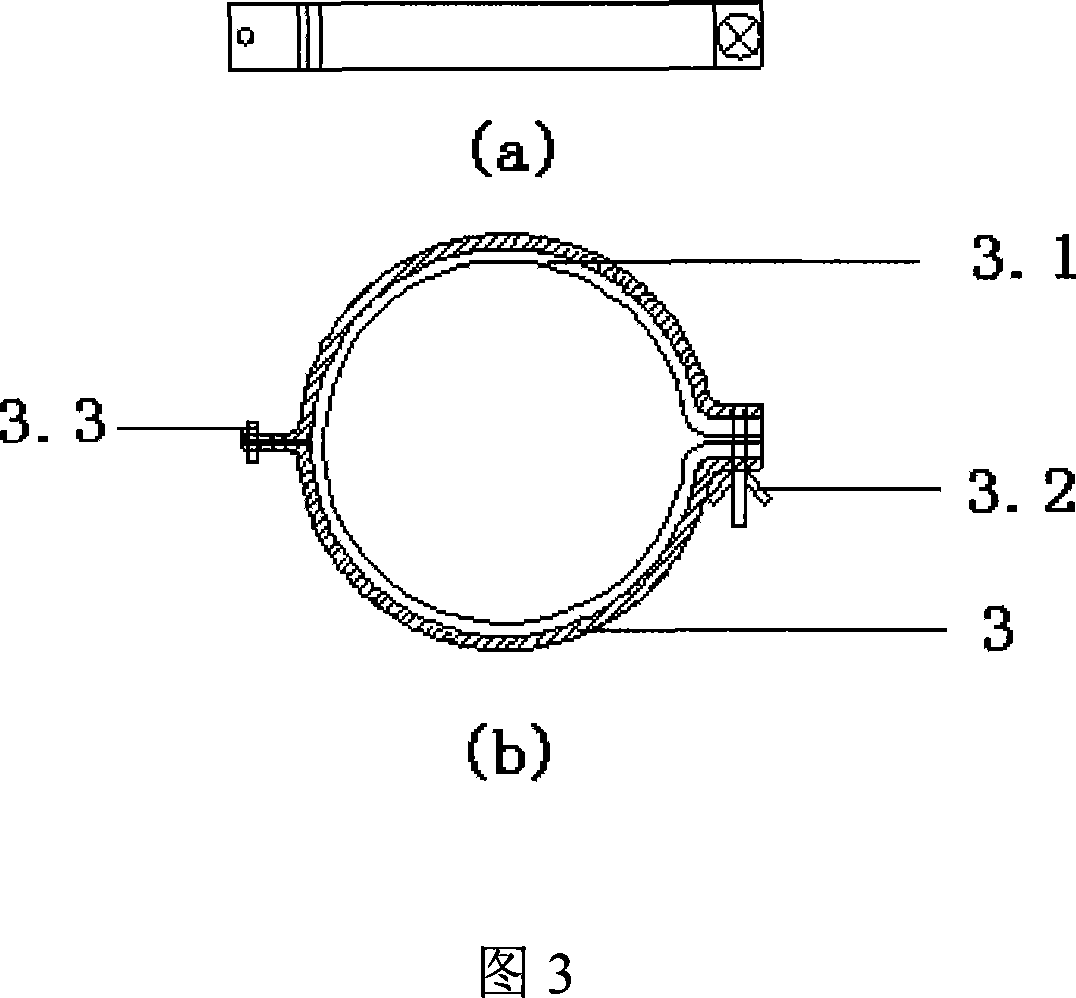

[0031] The scraps of gold-plated parts for electrical connectors and the leftovers produced in the production are made of resin composite boards. They are heated in nitric acid solution to make the gold flakes and resin composite board fragments fall off, and the mixture of gold flakes and resin composite board fragments is put into the 1, pour water into the transparent container, and stir again. When the stirring is stopped, it can be seen that the sedimentation speed of the gold flakes is slower than that of the matrix, and the solid fragments quickly sink to the bottom of the container, while the gold flakes are suspended in the water and gradually sink. At this time, open the side of the container If there is a jacket on the wall, the gold flakes flow out from the holes on the side wall of the container with water, and the solid fragments remain in the container; if a small amount of gold flakes remain in the container, they can be separated by repeated flushing. This meth...

Embodiment 2

[0033]The main board of the waste mobile phone and computer is broken into small pieces, and the gold foil on the surface of the waste material and the substrate are separated by adding nitric acid solution, and the mixture of the broken main board and the gold flake is filtered out, and the mixture of the gold flake and the main board fragment is put into the transparent container shown in Figure 1 , flush into water, and stir again. When the stirring is stopped, it can be seen that the settling speed of the gold flakes is slower than that of the matrix, and the solid fragments quickly sink to the bottom of the container, while the gold flakes are suspended in the water and gradually sink. At this time, open the jacket on the side wall of the container. Then the gold flakes flow out from the hole on the side wall of the container with water, and the solid fragments remain in the container; if a small amount of gold flakes still remain in the container, they can be separated by ...

Embodiment 3

[0035] Add the waste gold-plated circuit board into the nitric acid solution, after the gold foil on the surface of the waste material and the substrate fall off, filter out the mixture of the circuit board and the gold flakes, put the mixture of the gold flakes and the circuit board fragments into the transparent container shown in Figure 1, rinse Pour into water and stir again. When the stirring is stopped, it can be seen that the sedimentation speed of the gold flakes is slower than that of the matrix, and the solid fragments quickly sink to the bottom of the container, while the gold flakes are suspended in the water and gradually sink. At this time, the jacket on the side wall of the container is opened, and the gold The flakes flow out with the water from the hole on the side wall of the container, and the solid fragments remain in the container; if a small amount of gold flakes remain in the container, they can be separated by repeated flushing. This method utilizes the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com