Winding type spiral pipe heat exchanger

A spiral tube and heat exchanger technology, applied in the field of winding spiral tube heat exchangers, can solve the problem that the structure design of the heat exchanger cannot achieve the heat exchange technology without cross-contamination, the contact area between the thick tube and the thin tube is small, and the metal consumption is small. problem of large quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The principle and structure of the present invention will be further described below in conjunction with the accompanying drawings.

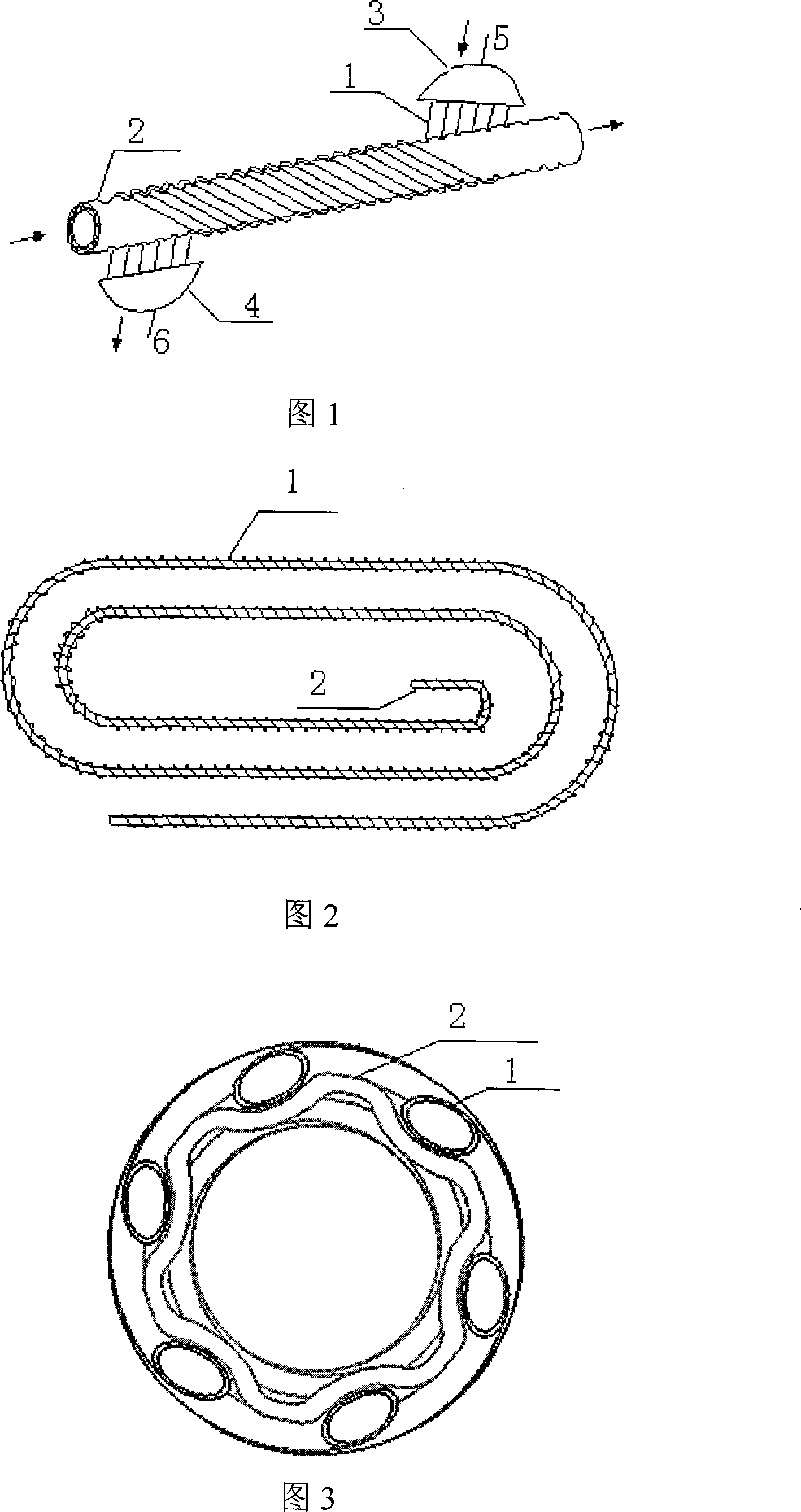

[0016] As shown in Figure 1, the wound spiral tube heat exchanger includes one or more thin tubes 1, one spiral tube 2, one or more distributors 3, one or more collectors 4, and the two ends of the thin tubes 1 are respectively It is connected with distributor 3 and collector 4 , distributor 3 is provided with inlet 5 , collector 4 is provided with outlet 6 , thin tube 1 is wound on spiral tube 2 .

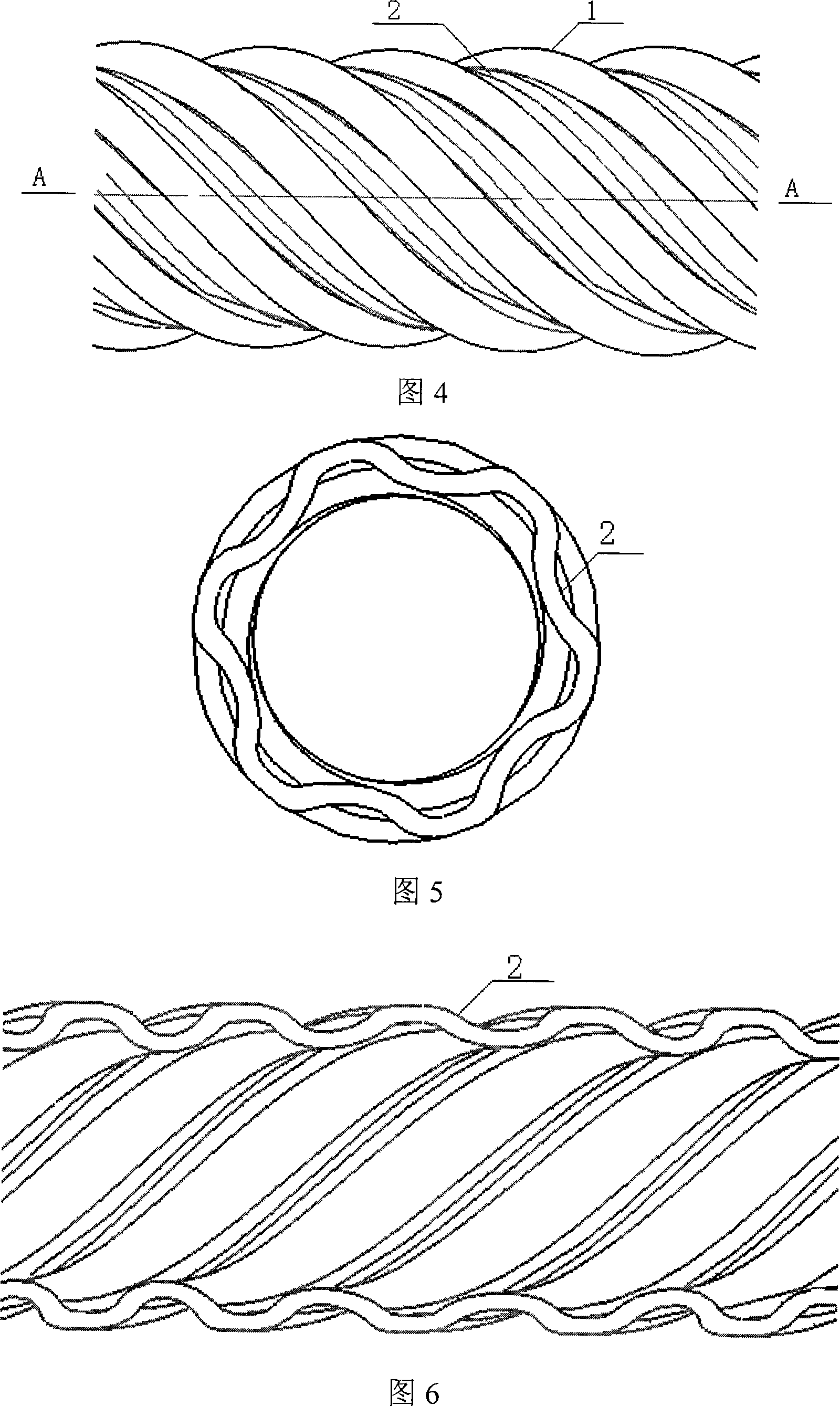

[0017] The thin tube 1 is wound in parallel and embedded in the groove on the outside of the helical tube. As shown in Figures 3 and 4, the thin tube is mechanically in close contact with the groove or connected by welding. The cross-sectional shape of the groove on the outer side of the spiral tube 2 is arc-shaped at the bottom, and the two sides of the upper part are streamline transitional profiles. The shape and structure of the wound s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com