Microbiological fuel cell of baffle plate air cathode

An air cathode and fuel cell technology, applied to biochemical fuel cells, fuel cell parts, battery electrodes, etc., can solve the problems of single wastewater type, low energy density, single structure, etc., to save reactor space and improve treatment Efficiency, the effect of improving power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

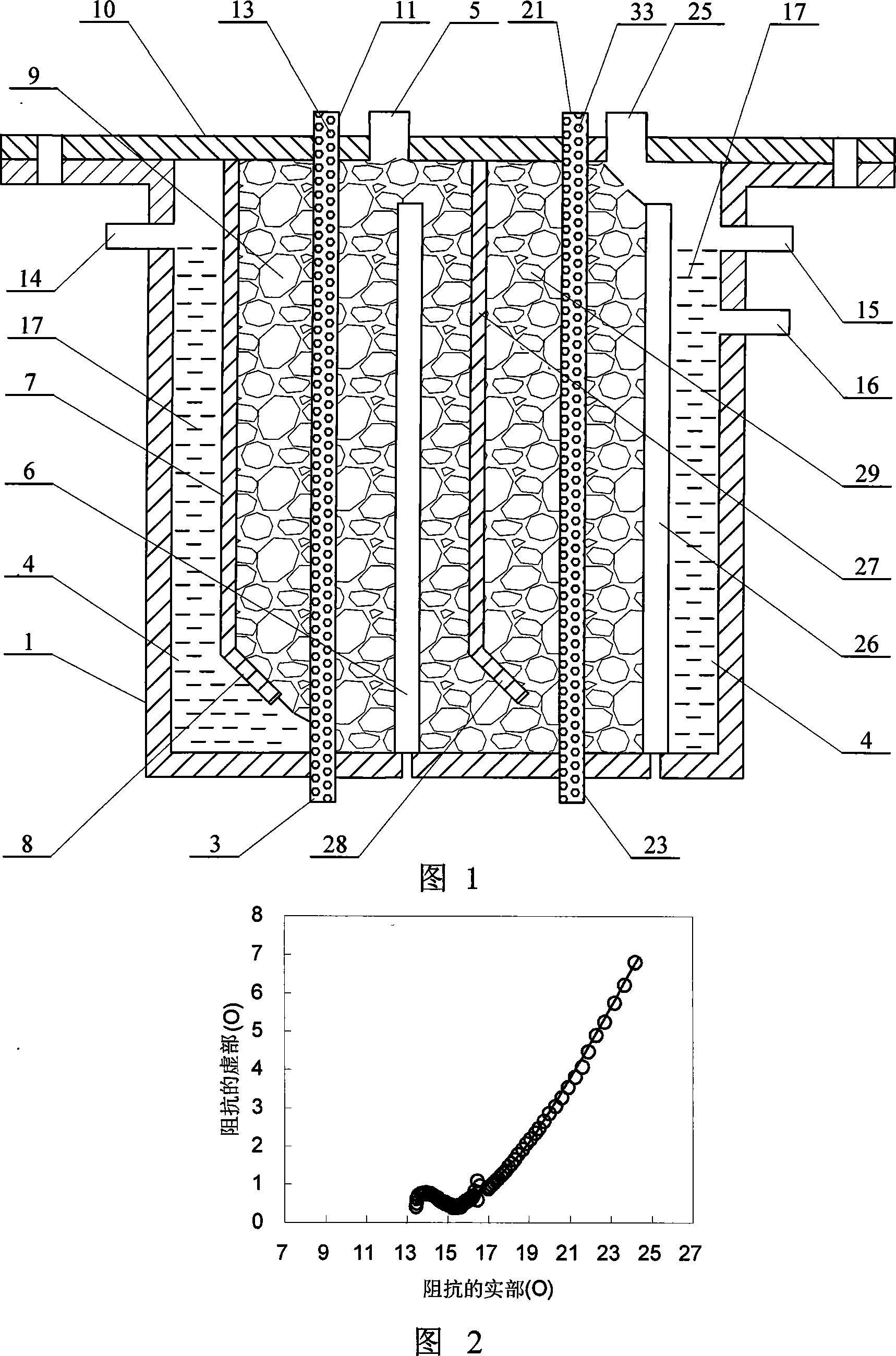

[0008] Specific embodiment one: (referring to Fig. 1) present embodiment is made up of box body 1, the first three-dimensional solid anode, the first air cathode 3, the first plastic baffle plate 7, sealing cover 10 and solution 17, on the sealing cover 10 A first sampling port 5 is provided, a water inlet 14 is provided on one side of the upper part of the side wall of the cabinet 1, a water outlet 15 is provided on the other side of the upper part of the side wall of the cabinet 1, and a sealing cover is provided on the top of the cabinet 1 10. The box body 1 is sealed and connected with the sealing cover 10. The anode chamber 4 is between the sealing cover 10 and the cavity of the box body 1. The first air cathode 3 is arranged between the sealing cover 10 and the box body 1. The first air cathode The upper end of 3 is fixedly connected with the sealing cover 10 and communicated with the atmosphere. The lower end of the first air cathode 3 is fixedly connected with the botto...

specific Embodiment approach 2

[0009] Specific embodiment two: (referring to Fig. 1) the difference between this embodiment and specific embodiment one is that it has increased the second three-dimensional anode, the second air cathode 23 and the second plastic baffle plate 27, the second three-dimensional anode , the second air cathode 23 and the second plastic baffle 27 are all arranged in parallel with the first three-dimensional solid anode, the first air cathode 3 and the first plastic baffle 7, and the second air cathode 23 is arranged between the sealing cover 10 and the box Between the body 1, the upper end of the second air cathode 23 is fixedly connected with the sealing cover 10 and communicated with the atmosphere, the lower end of the second air cathode 23 is fixedly connected with the bottom of the box body 1 and communicated with the atmosphere, the second air cathode 23 It is composed of a second cylindrical plastic substrate 21 covered with carbon cloth on the surface. The second cylindrical...

specific Embodiment approach 3

[0011] Embodiment 3: (see FIG. 1 ) The difference between this embodiment and Embodiment 1 is that a return port 16 is provided on the box body 1 below the water outlet 15 . The return port 16 is used to connect with the return device, and return part of the outlet water to the tank 1 through the water inlet 14 for reuse. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Chamfer | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com