Laser-control flattening bulldozer

A technology of bulldozers and lasers, which is applied to mechanically driven excavators/dredgers, etc., can solve the problems of many observations and manipulations, high labor intensity, and difficulty in control, so as to reduce labor intensity of workers, improve construction quality, The effect of increased construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

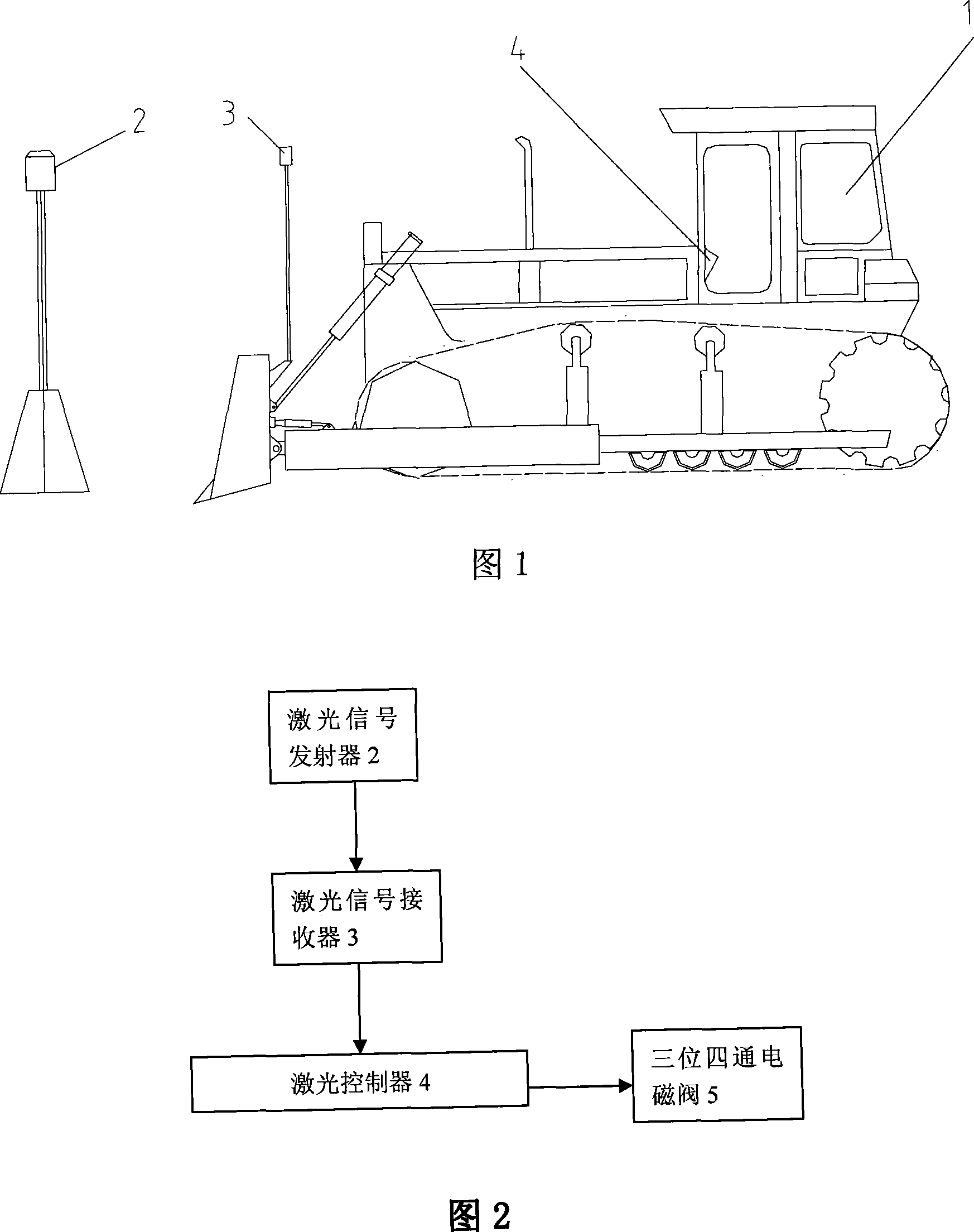

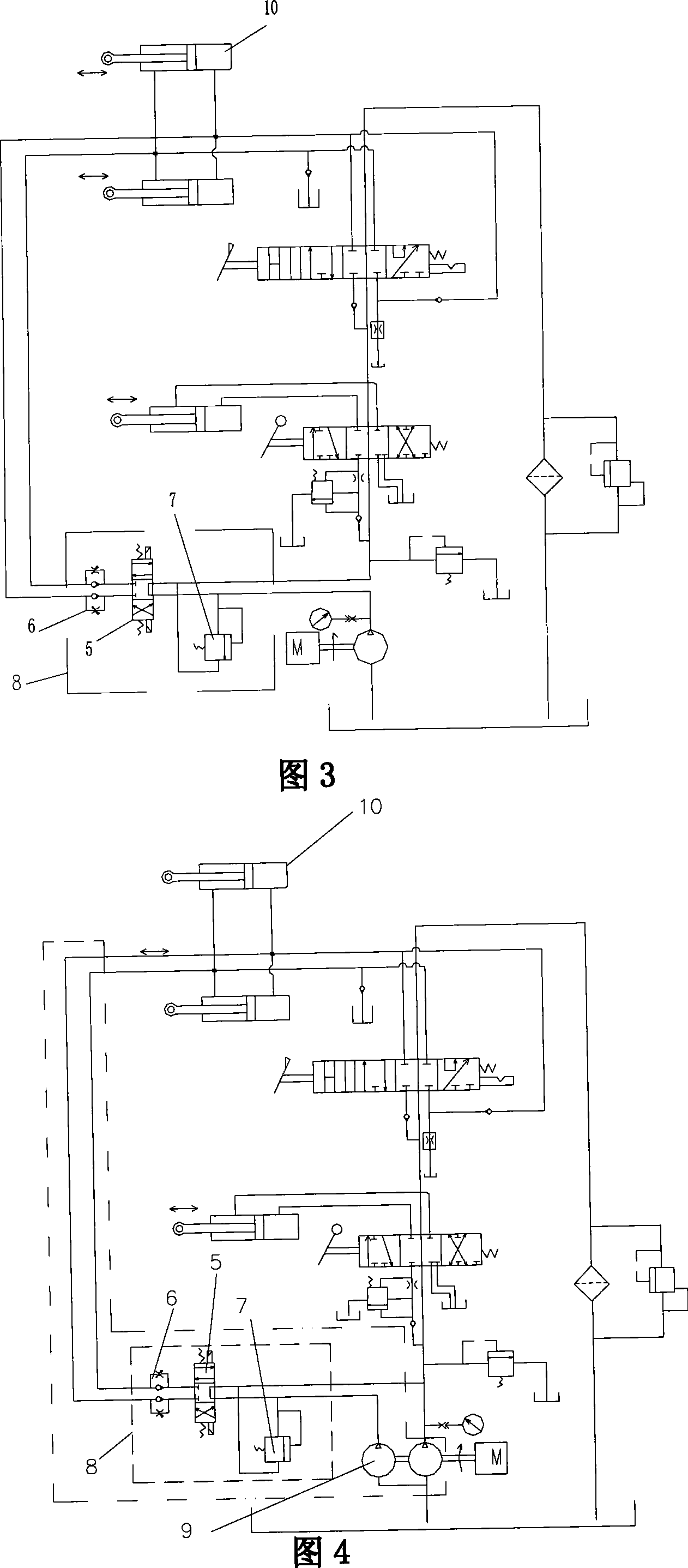

[0013] As shown in Figure 1, Figure 2, and Figure 3, a laser-controlled leveling bulldozer includes a bulldozer 1, a laser signal transmitter 2, a laser signal receiver 3, a laser controller 4, a three-position four-way solenoid valve 5, and a damping valve 6. Safety valve 7, integrated valve block 8, double pump 9 and blade lifting cylinder 10, a laser signal receiver 3 is provided above the blade on the bulldozer 1, and a laser controller 4 is installed in the cab of the bulldozer 1, The laser signal receiver 3 is connected to the laser controller 4 through wires, the laser signal transmitter 2 is placed at an appropriate position on the construction site, and the upper and lower positions of the laser transmitter 2 are changed by lifting the handle of the laser transmitter 2, thereby determining the reference plane of the laser signal , the three-position four-way solenoid valve 5, the damping valve 6 and the safety valve 7 are integrated on the integrated valve block 8 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com