Novel vertical multipurpose standard pressure boiler

A multi-purpose, vertical technology, applied in the direction of lighting and heating equipment, fluid heaters, water heaters, etc., can solve the problems of increased heat loss, complex structure, increased input costs, etc., to achieve long service life and low heat loss of the system Less, cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

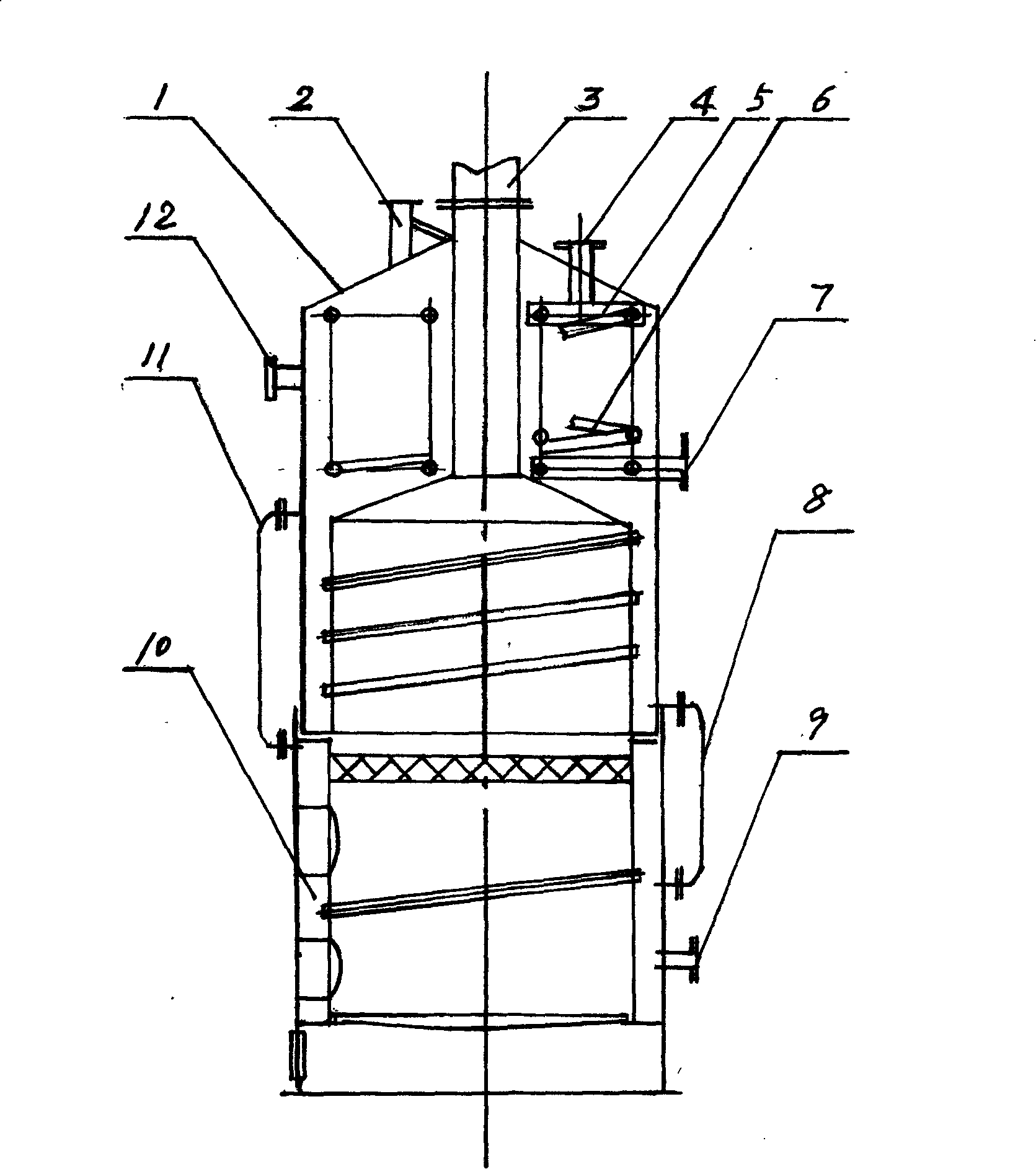

[0016] Such as figure 1 As shown, the embodiment of the present invention includes an upper furnace body 1, a lower furnace body 10 and a chimney 3 derived from the furnace body. A first water inlet pipe 9 is arranged on the lower furnace body 10 , and a first water outlet pipe 12 and an exhaust pipe 2 are arranged on the upper furnace body 1 . Both the upper furnace body 1 and the lower furnace body 10 are made of carbon steel, and they are connected through the ascending pipe 11 and the descending pipe 8 to realize heat circulation between the upper and lower furnace bodies.

[0017] A group of heat exchange tubes 6 is installed in the upper furnace body 1 with a second water inlet pipe 7 and a second water outlet pipe 4 leading to the outside of the upper furnace body 1 . The shape of this group of heat exchange tubes 6 is helically coiled, and the specific installation method is: they are all helically coiled with the chimney 3 at the center of the upper furnace body 1 as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com