Method for forming phototonus combination, direction distribution membrane and optical compensation membrane

A photosensitive composition and photosensitivity technology, applied in nonlinear optics, optics, optomechanical equipment, etc., can solve problems such as dust pollution, unsuitable wide viewing angle, scratches, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

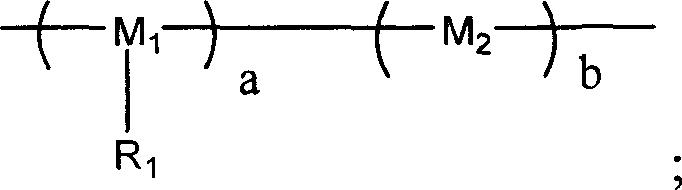

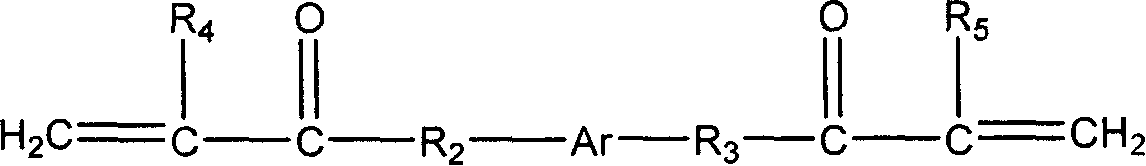

[0033] Copolymer of 4-(methacrylamido)phenylmethacrylate and perfluorinated propyl methacrylate1

[0034] Take 0.5g (2mmol) of 4-(methacrylamide) phenyl methacrylate, 0.375g (1.4mmol) of perfluorinated propyl methacrylate (2,2,3,3-tetrafluoropropylmethacrylate) and 0.00875g of AIBN was dissolved in 10mL of DMF and isolated from the air. After reacting at 80°C for 20 minutes, the reactant was slowly dropped into diethyl ether (200mL) under stirring at room temperature. After filtration, 0.374 g (42.7% yield) of copolymer 1 was obtained. IR(KBr), cm -1 : Broad peak (broad) 3430, 3350 (N-H), 1750 (-O-C-O-), 1670 (amide), 1510, 1260, 962, 945, 879, 661 (aryl), other signals such as 2940, 1410, 1390, 1320, 1200, 1170, 1130, 1100, 1002, 833, 525.

[0035] Copolymer of 4-(methacrylamido)phenyl methacrylate and perfluorinated propyl methacrylate 2

[0036] Take 0.91g (4mmol) of 4-(methacrylamido)phenyl methacrylate, 1g (5mmol) of perfluorinated propyl methacrylate and 0.0191g of A...

Embodiment 1-2

[0050] Preparation of Alignment Film

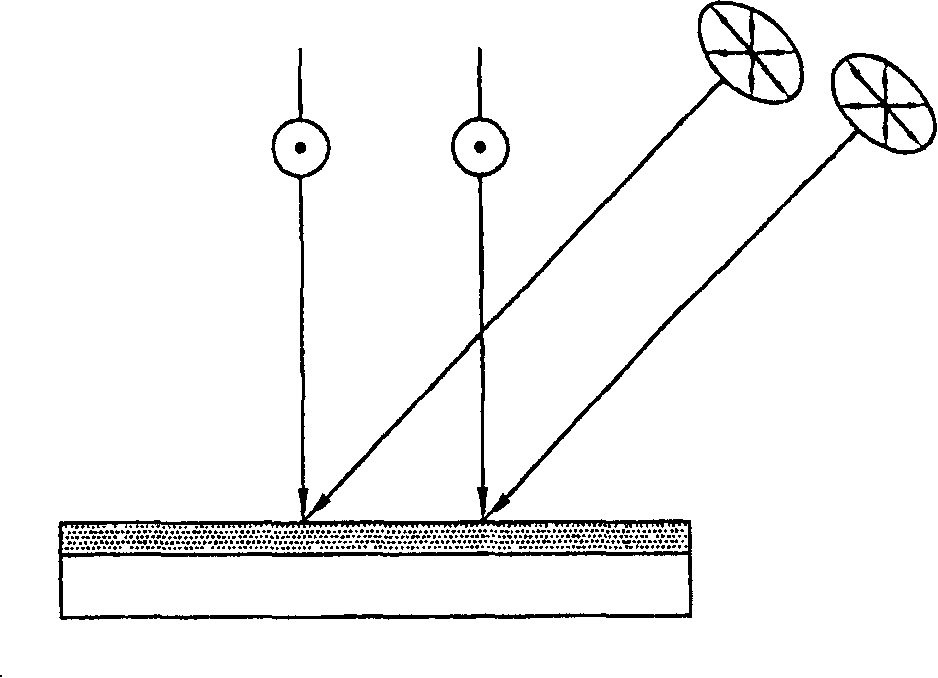

[0051] 80 parts by weight of copolymer 1-8, 10 parts by weight of dipentylthritol hexaacrylate (DPHA), and 5 parts by weight of photoinitiator were respectively dissolved in DMF to form a photosensitive composition solution. Then, the above solution was spin-coated onto the glass containing the ITO electrode at a speed of 3500 rpm, and baked at 180° C. for 1.5 hours to remove DMF. Then the substrate is taken out from the oven and returned to room temperature, and the photosensitive composition film on the substrate is irradiated with ultraviolet rays generated by a high-pressure mercury lamp, such as figure 1 shown. First, irradiate the film with polarized ultraviolet light at an angle of 45 degrees (exposure amount is about 50mJ / cm 2 ). Afterwards, a polarizing plate was added, and the film was irradiated vertically with unpolarized ultraviolet light (exposure amount was about 50mJ / cm 2 ), forming an alignment film. The above polari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com