Sensing type packaging part and manufacturing method thereof

A packaging and sensing technology, applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve the problems of film residue, increased process cost and steps, dam structure and substrate delamination, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The implementation of the present invention is described below through specific examples, and those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification.

[0039] see Figure 2A FIG. 2F is a schematic diagram of the sensing package and its manufacturing method of the present invention.

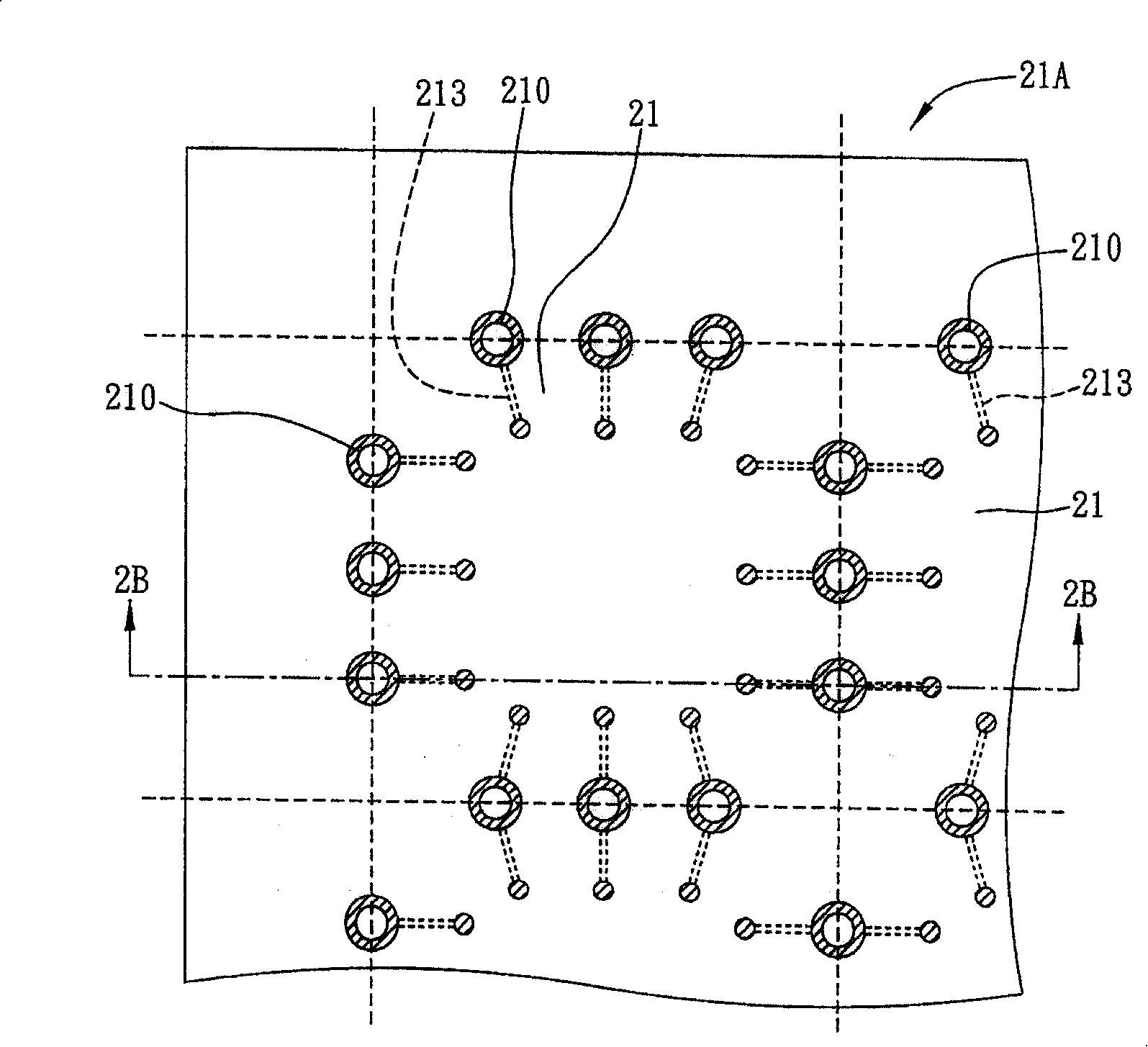

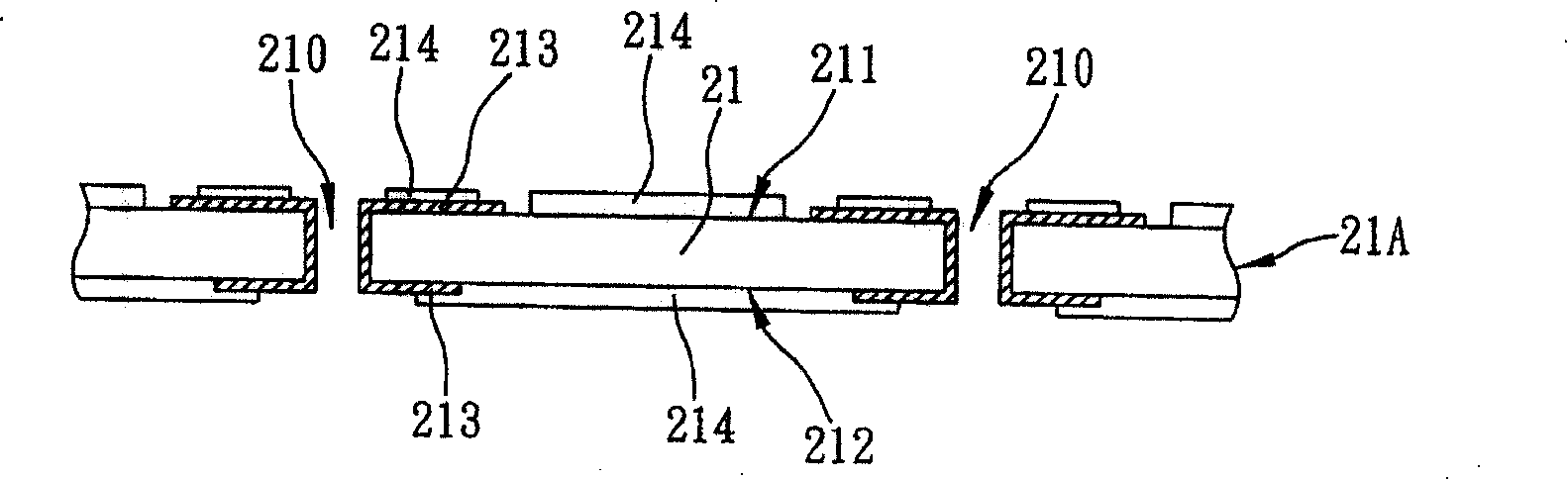

[0040] Such as Figure 2A and Figure 2B shown, where the Figure 2B for correspondence Figure 2A Firstly, a substrate module sheet 21A with a plurality of substrates 21 arranged in an array is provided, and a plurality of electrical via holes 210 are provided between adjacent substrates 21 .

[0041] The substrate 21 has opposite first surface 211 and second surface 212, the substrate first and second surfaces 211, 212 are provided with a plurality of conductive lines 213, and through the electrical conductors formed between the adjacent substrates 21 through holes 210 to electrically conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com