Translucent type thin-film solar cell module and manufacturing method thereof

A technology of solar cells and manufacturing methods, applied in photovoltaic power generation, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems affecting process yield, expensive related equipment, and increased costs, so as to improve light transmittance and increase Effect of Process Yield and Solar Cell Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Figure 4a to Figure 9c It is a schematic flowchart of a manufacturing method of a light-transmissive thin-film solar cell module according to an embodiment of the present invention. in, Figure 4a , 5a , 6a, 7a, 8a, 9a are diagrams showing the top view, Figure 4b , 5b , 6b, 7b, 8b, 9b, 9b' are schematic cross-sectional views along the section line I-I', Figure 9c is a schematic cross-sectional view along the section line II-II'.

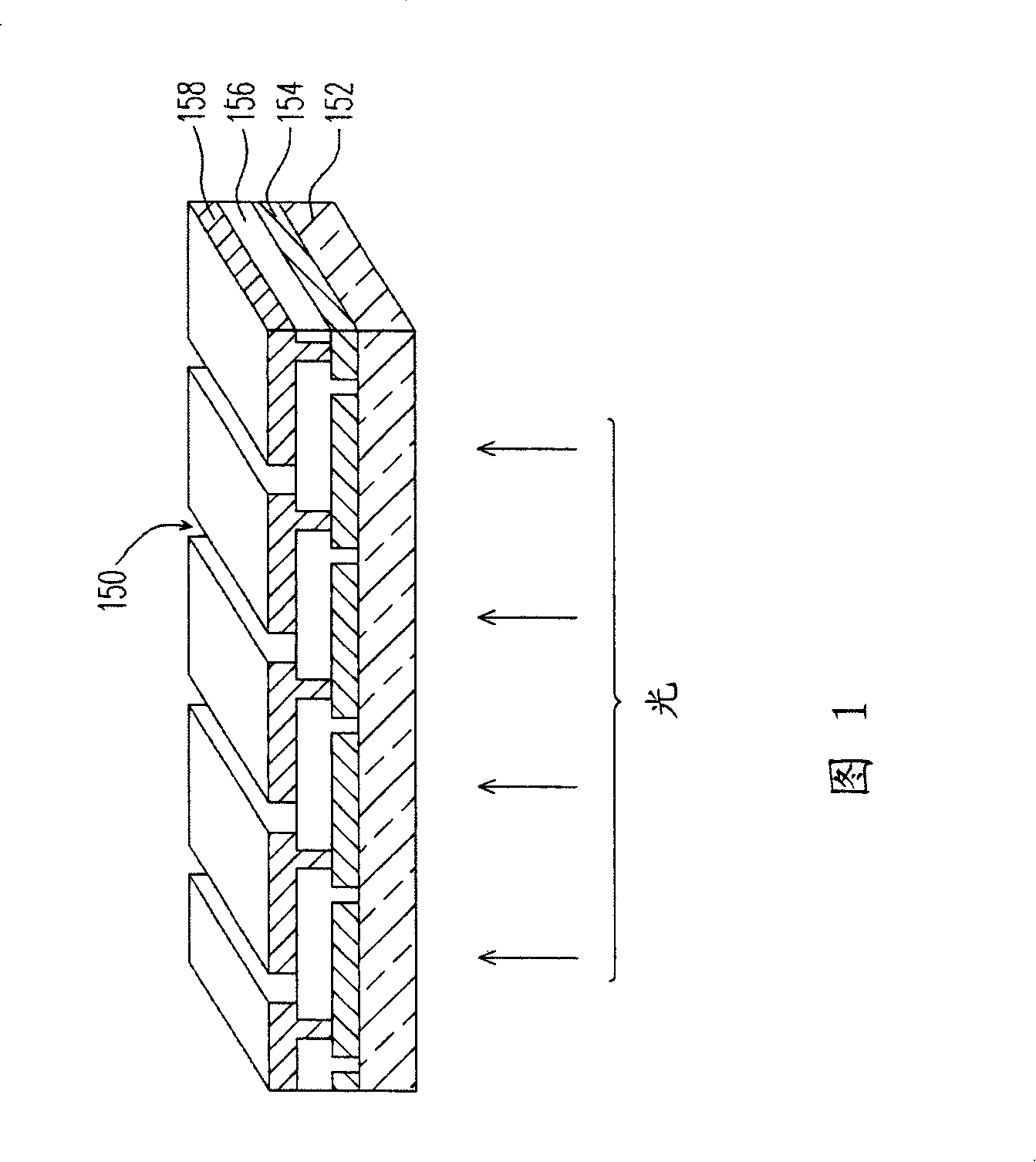

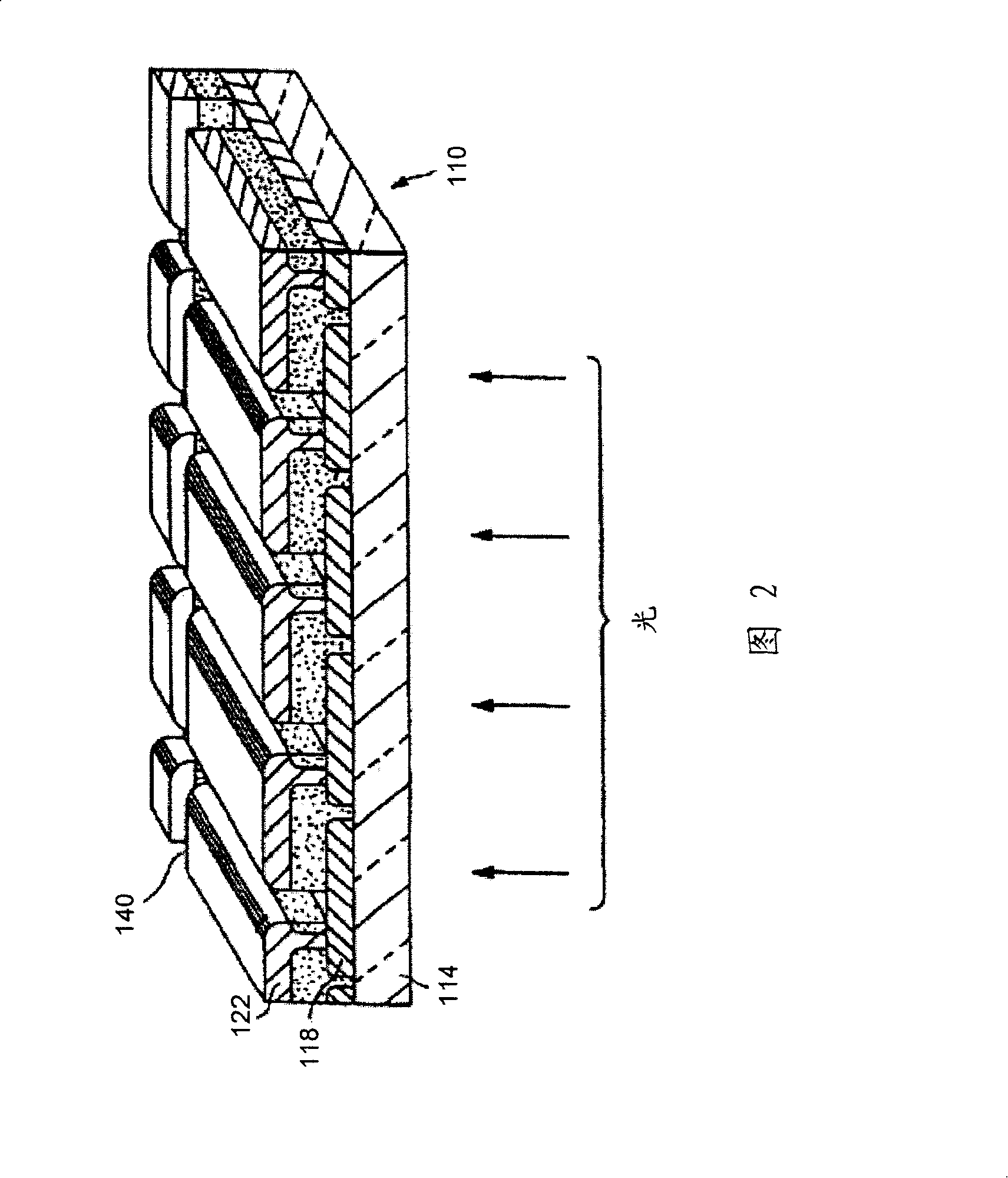

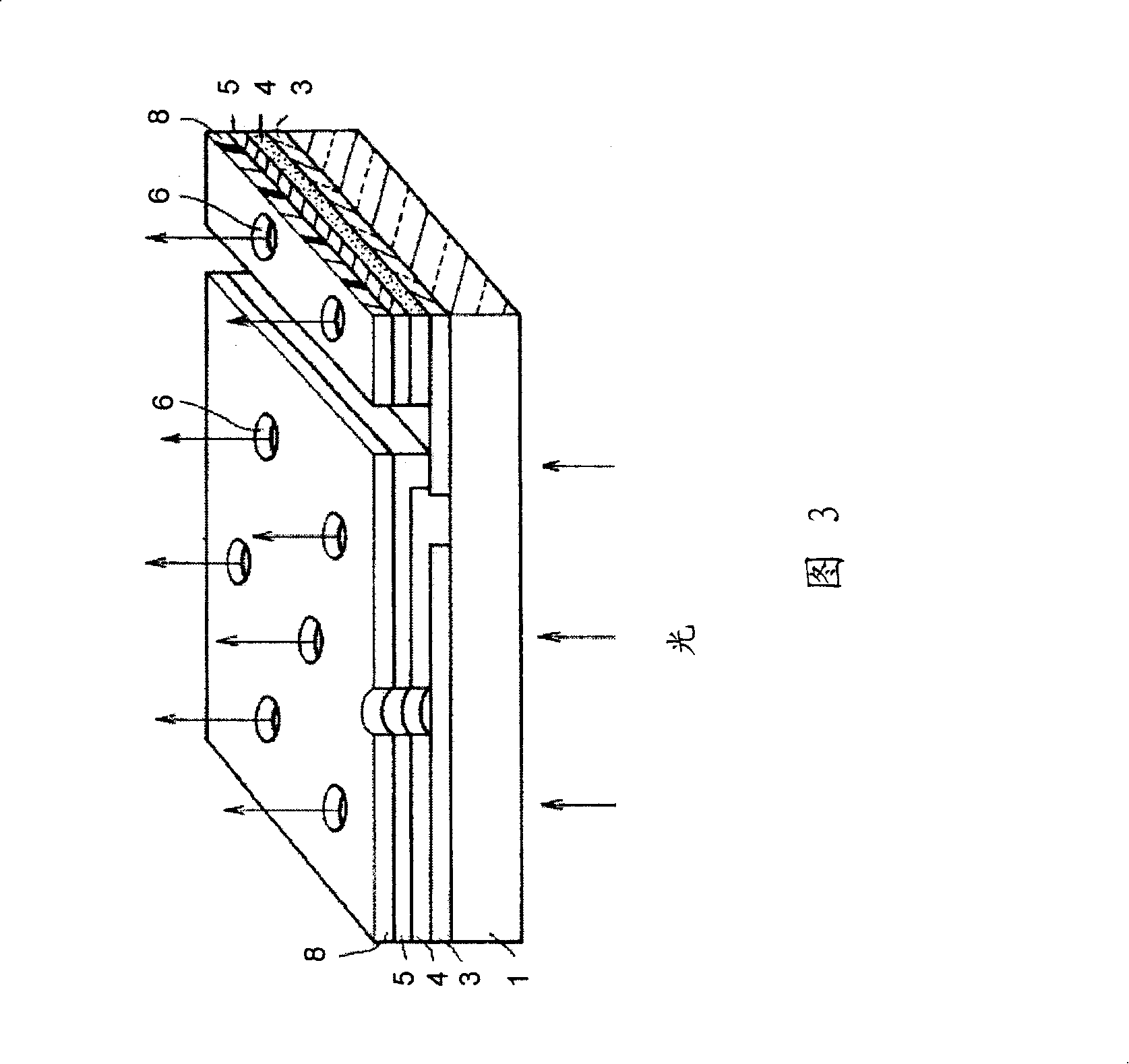

[0045] First, please refer to Figure 9a , Figure 9b , Figure 9b 'and Figure 9c , the light-transmissive thin-film solar cell module 400 of this embodiment is composed of a plurality of cells (cells) 401 connected in series. Moreover, a plurality of X-direction openings 422 and Y-direction openings 420 of the transparent substrate 402 are exposed between the cells 401 . Therefore, when light (sunlight) irradiates from the bottom of the transparent substrate 402 , it can pass through the X-direction opening 422 and the Y-directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com