Electromagnetic stove mating iron pan and manufacturing method thereof

A manufacturing method and induction cooker technology, applied in cooking utensils, household utensils, applications, etc., can solve the problems of easy-to-deform components, unfavorable human health, and low structural strength, so as to eliminate adverse effects, benefit human health, and structure high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

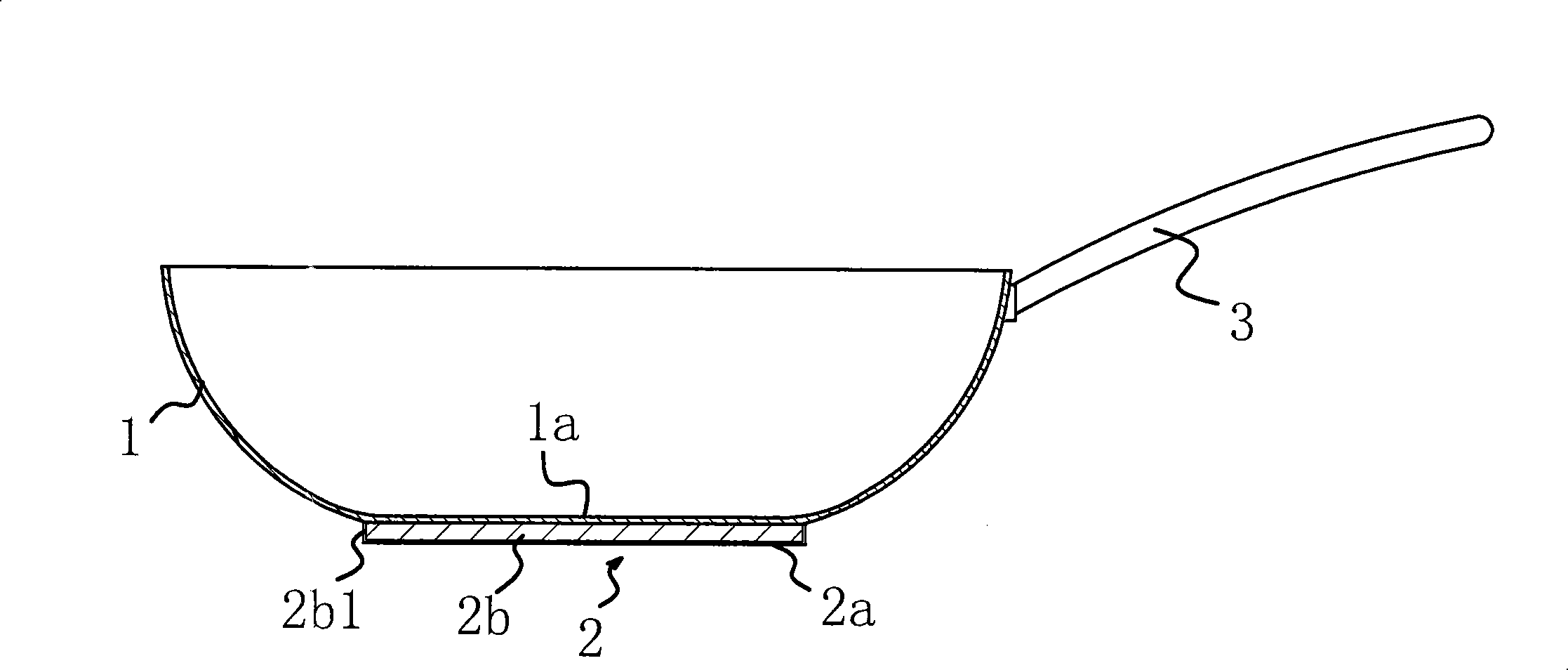

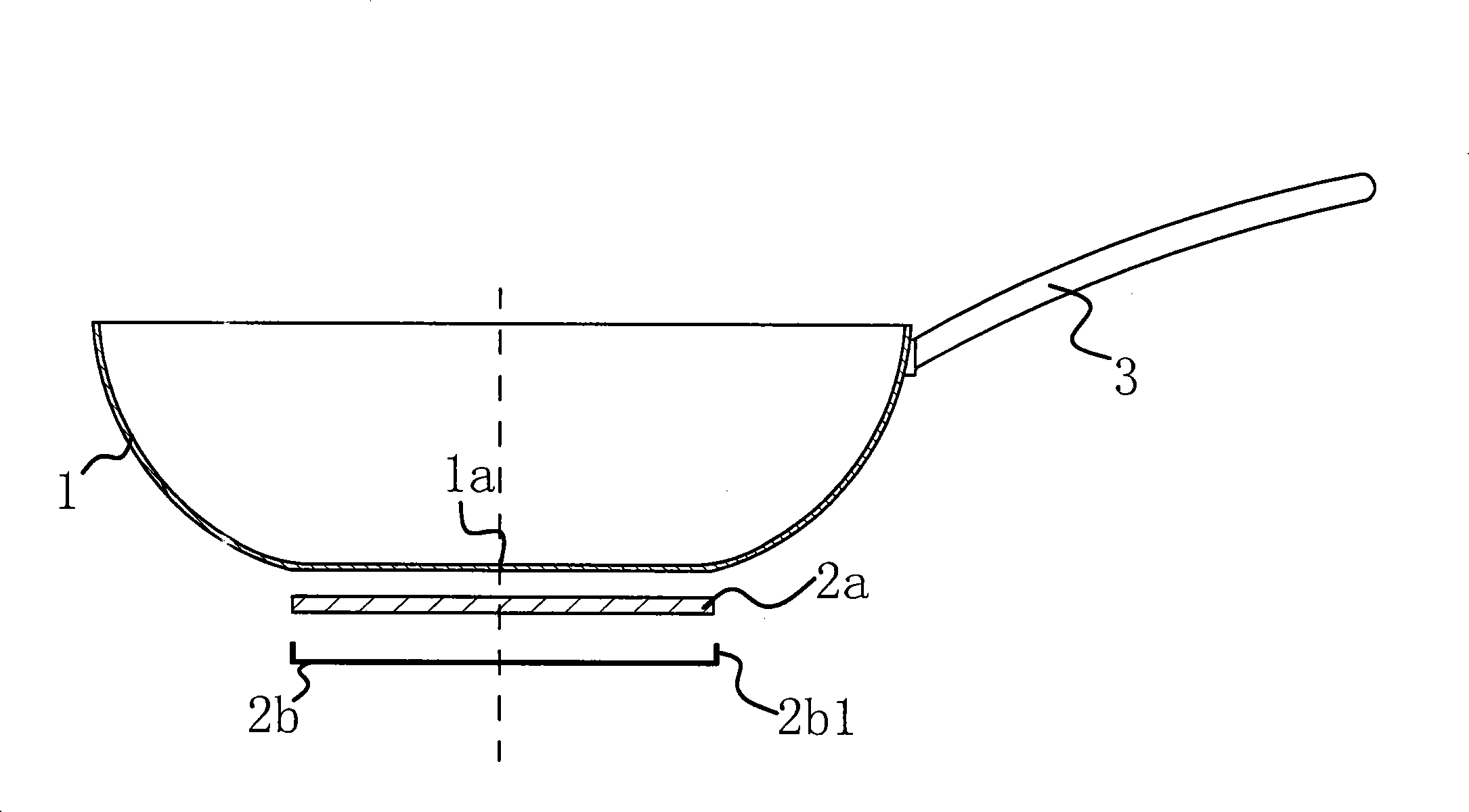

[0025] Such as figure 1 and figure 2 As shown, the electromagnetic cooker companion iron pan includes a pan body 1 made of iron with a flat bottom 1a, a smooth transition between the inner wall of the pan body 1 and the flat bottom 1a, and a heating pan at the bottom of the pan body flat bottom 1a. negatives2. The bottom sheet 2 is a multi-layer composite structure, including a thermally conductive layer 2a made of aluminum fixed on the bottom of the pot body 1, and a bottom layer 2b made of magnetically conductive material is fixedly connected to the thermally conductive layer 2a. The size of the heat-conducting layer 2a is adapted to the size of the flat bottom 1a of the pot body, and the bottom layer 2b is slightly larger than the heat-conducting layer 2a, and wrapping 2b1 is formed on the periphery of the heat-conducting layer 2a, and the wrapping 2b1 is vertically arranged with the bottom layer 2b. The heat conducting layer 2a is pressure-welded between the flat bottom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com