Infrared shielding film-coated glass plate and production process therefor

A manufacturing method and a technology for a blocking layer, which are applied to a glass plate with an infrared blocking layer and the manufacturing field thereof, can solve the problems of low chemical resistance and cannot be applied, and achieve high radio wave transmittance, simplified manufacturing method, and visible light transmission. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

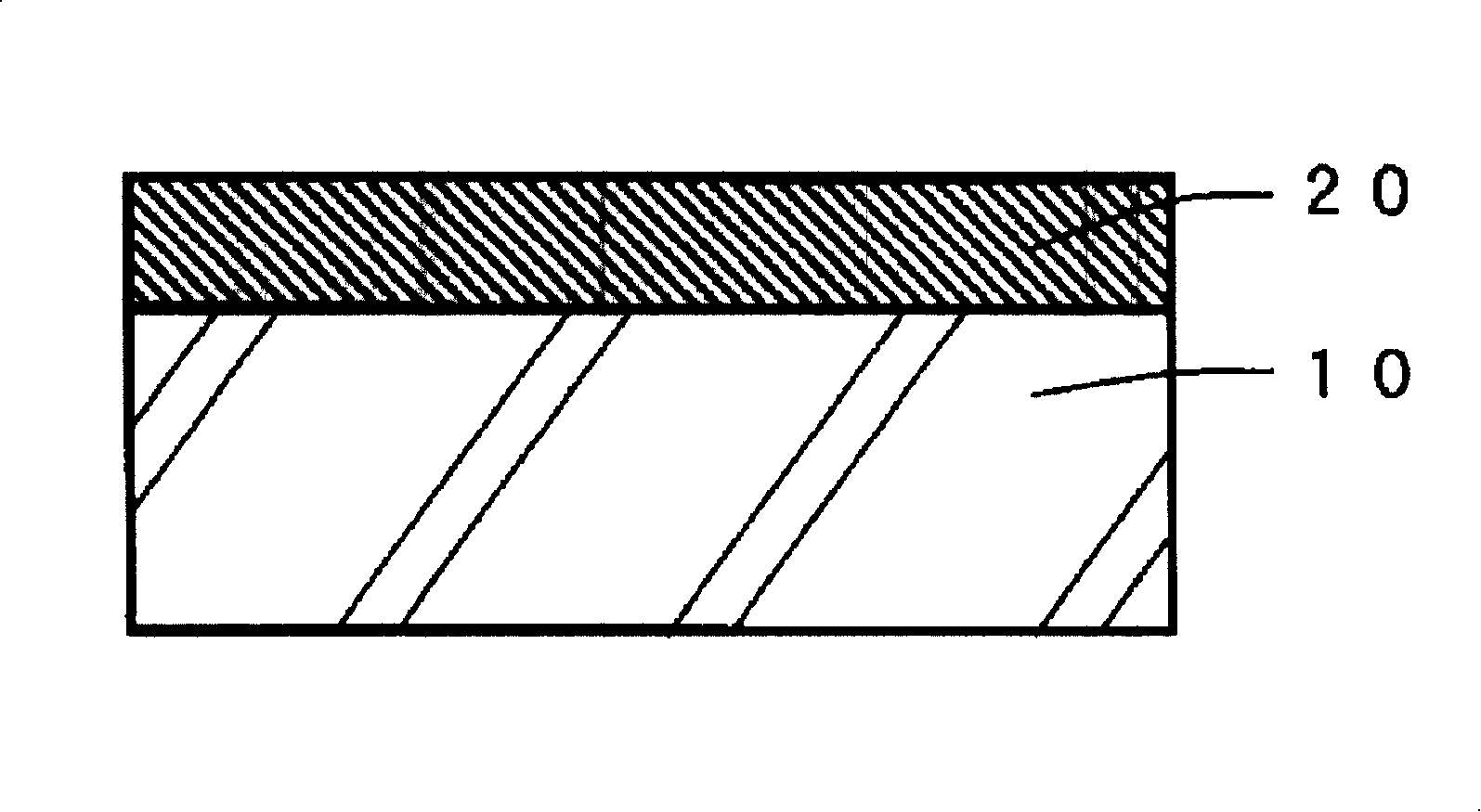

Image

Examples

example 1

[0060] Measure the xylene dispersion A containing 30% by mass c light source, the powder color on the xy chromaticity coordinates under 2° field of view is (x, y)=(0.353, 0.374) and the primary particle diameter is 55nm ITO microparticles 0.43g, containing 20 mass% chemical formula-SiR 1 2 -NR 2 -SiR 1 2 - Medium R 1 =H and methyl, R 2 0.90 g of a xylene solution B of a partially organic polysilazane (manufactured by AZ-Electronics Co., Ltd., trade name: Aquamica NN-310) of H, and diisopropoxybis(ethyl acetoacetate)titanium (manufactured by Matsumoto Pharmaceutical Co., Ltd., brand name: TC-750) 0.67 g, these were mixed at room temperature, and stirred for 10 minutes to obtain a dispersion liquid C.

[0061] High-heat ray-absorbing green glass (Tv: 72.8%, Te: 45.2%, transmittance of light with a wavelength of 2.0 μm: 47.1%, 10 cm in length, 10 cm in width, and 3.5 cm in thickness, produced by Asahi Glass Co., Ltd. The obtained dispersion liquid C was coated by spin coat...

example 2

[0065] 0.52 g of the above-mentioned dispersion A, 1.51 g of the above-mentioned solution B, and 0.91 g of the above-mentioned diisopropoxybis(ethylacetoacetate)titanium were weighed, mixed at room temperature, and stirred for 10 minutes to obtain a dispersion D.

[0066] A glass plate with an infrared blocking layer was obtained in the same manner as in Example 1, except that dispersion D was used instead of dispersion C, and the thickness of the fired infrared blocking layer was changed as shown in Table 1. Table 1 shows the property evaluation results of the obtained glass plate with an infrared blocking layer.

example 3

[0068] 0.48 g of the above-mentioned dispersion A, 1.51 g of the above-mentioned solution B, and 0.99 g of the above-mentioned diisopropoxybis(ethylacetoacetate)titanium were weighed and mixed at room temperature, followed by stirring for 10 minutes to obtain a dispersion E.

[0069] A glass plate with an infrared blocking layer was obtained in the same manner as in Example 1, except that the dispersion E was used instead of the dispersion C, and the thickness of the infrared blocking layer after firing was changed as shown in Table 1. Table 1 shows the property evaluation results of the obtained glass plate with an infrared blocking layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com