Impressed electric field pollution-free deoxygenation refining method and device for ladle furnace

A technology of external electric field and ladle furnace, applied in the field of metallurgical refining process, can solve the problems of unsatisfactory deoxidation depth and deoxidation speed, affecting steel quality and performance, non-metallic inclusions polluting molten steel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

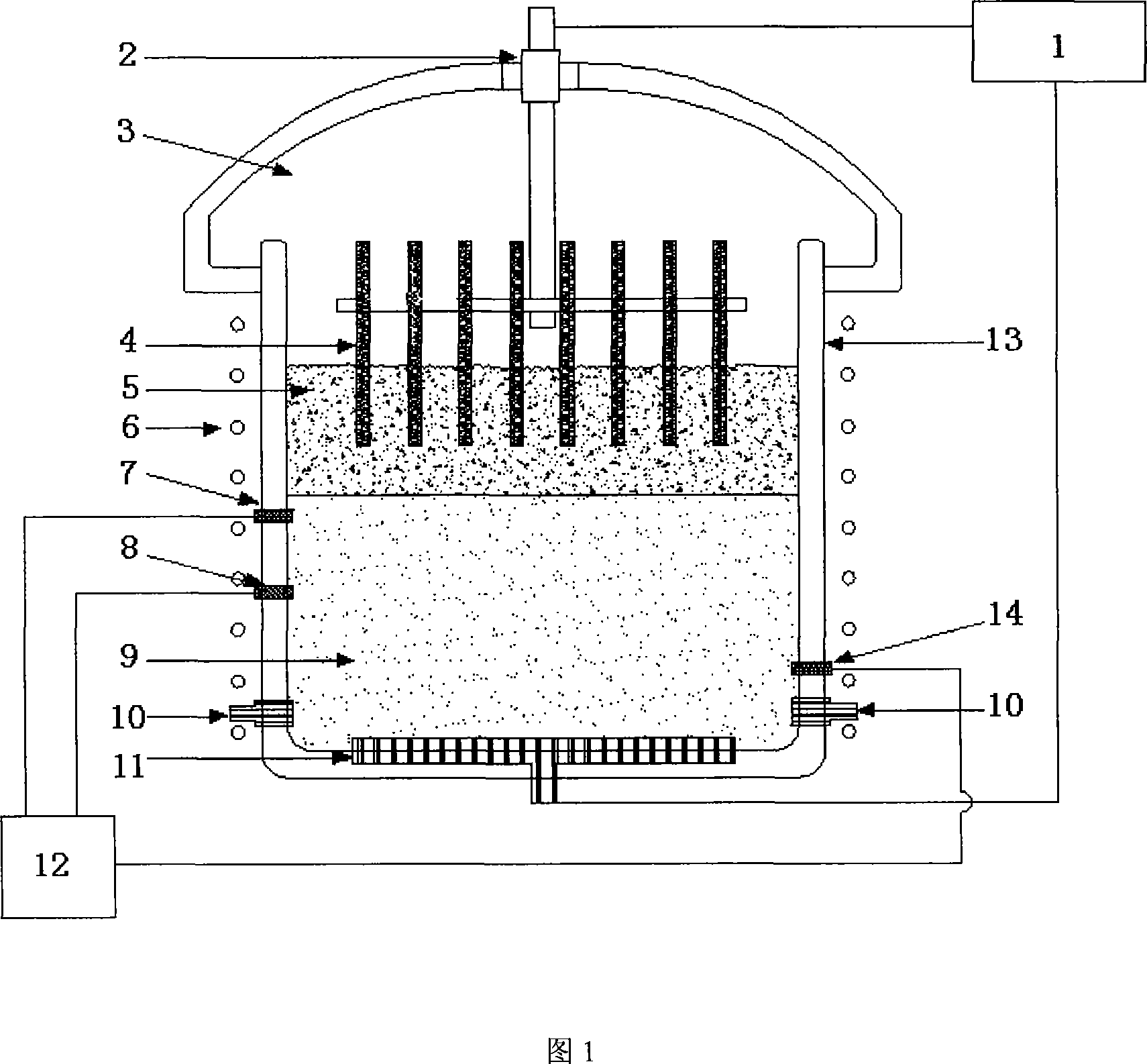

[0015] Referring to Figure 1, this special device includes: DC power supply system 1, anode lifting device 2, furnace atmosphere space 3, anode 4, slag 5, electromagnetic heating system 6, oxygen measuring instrument 7 and 14, temperature measuring instrument 8 , molten steel 9, air blowing stirring device 10, cathode 11, automatic data recording analyzer 12 and ladle furnace 13. In the furnace atmosphere space 3 at the top of the ladle furnace 13, an anode lifting device 2 is arranged in the center. The cross bar of this elevating device 2 is equipped with some graphite rod anodes 4 arranged vertically in parallel, and the lower end part of the anode 4 is inserted in the molten slag 5 of upper part in the furnace; Adjustment; the bottom of the molten steel 9 in the furnace is provided with evenly dispersed and spaced cathodes 11; the anode 4 at the top and the cathode 11 at the bottom are respectively connected to the positive and negative poles on the DC power supply system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com