Conductance tracking correlation method for downflow well flow measurement

A technology for flow measurement and injection wells, which is applied in the directions of measurement, earthwork drilling and production, wellbore/well components, etc., and achieves the effect of wide application fields and low start-up displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing:

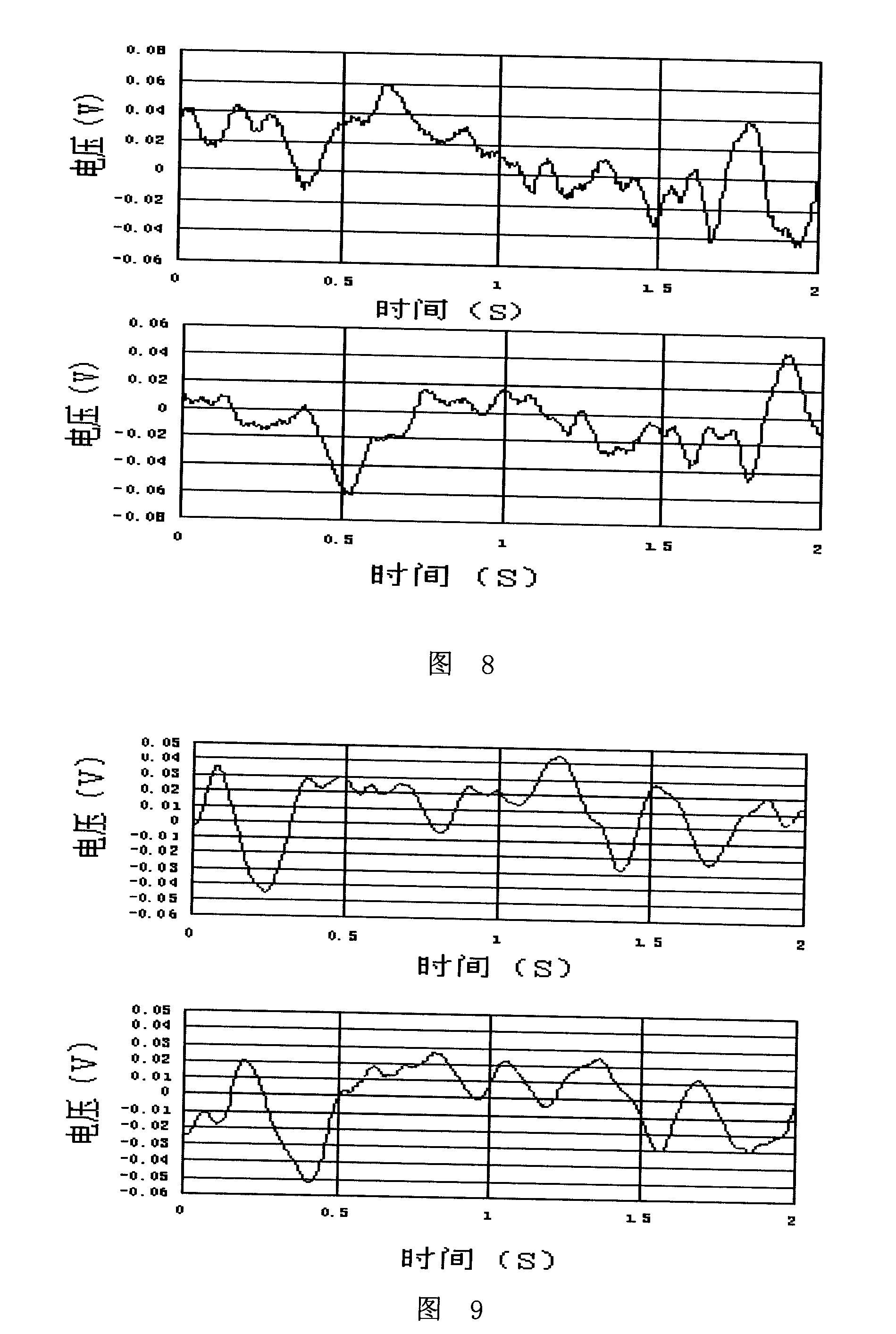

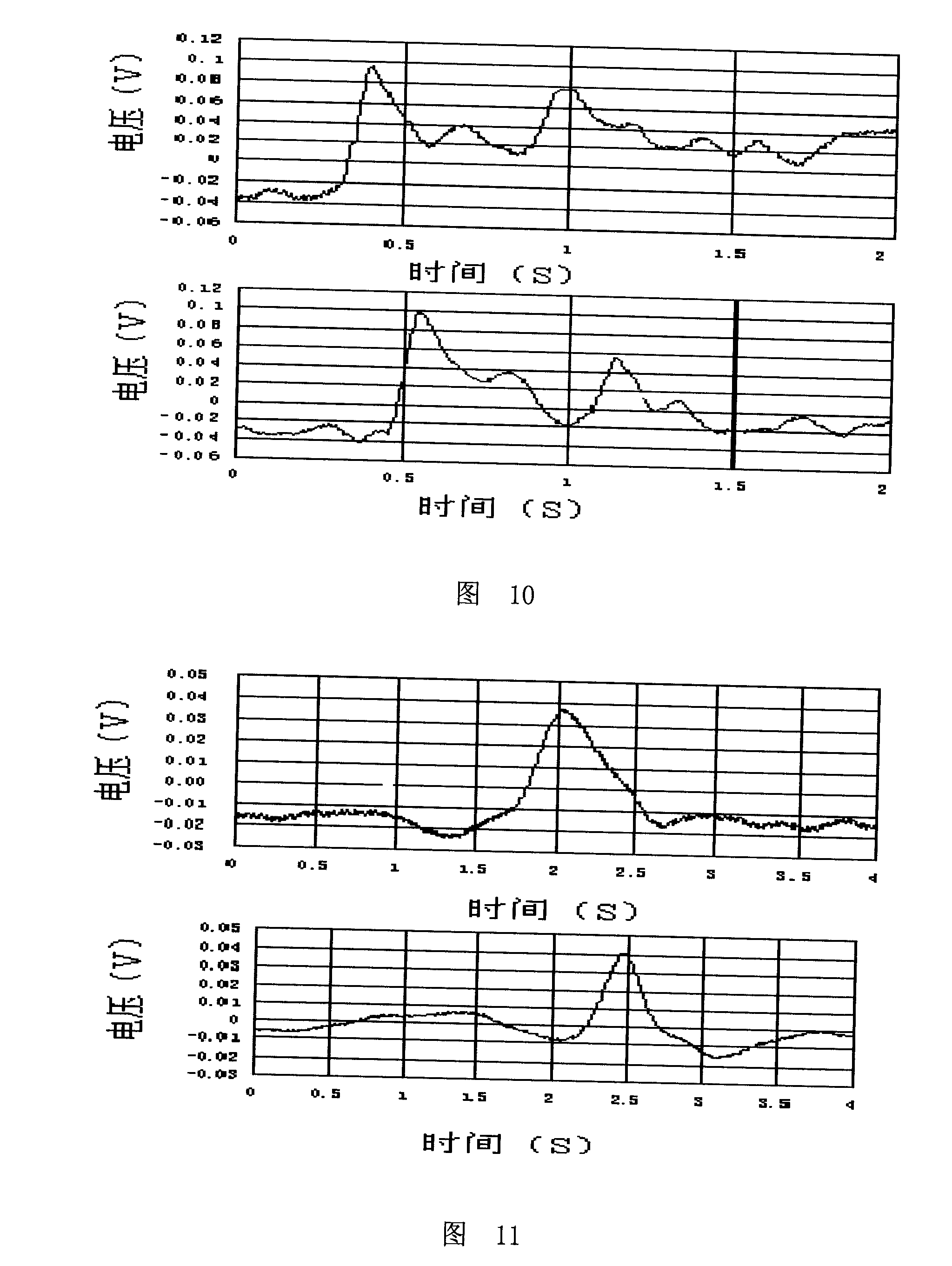

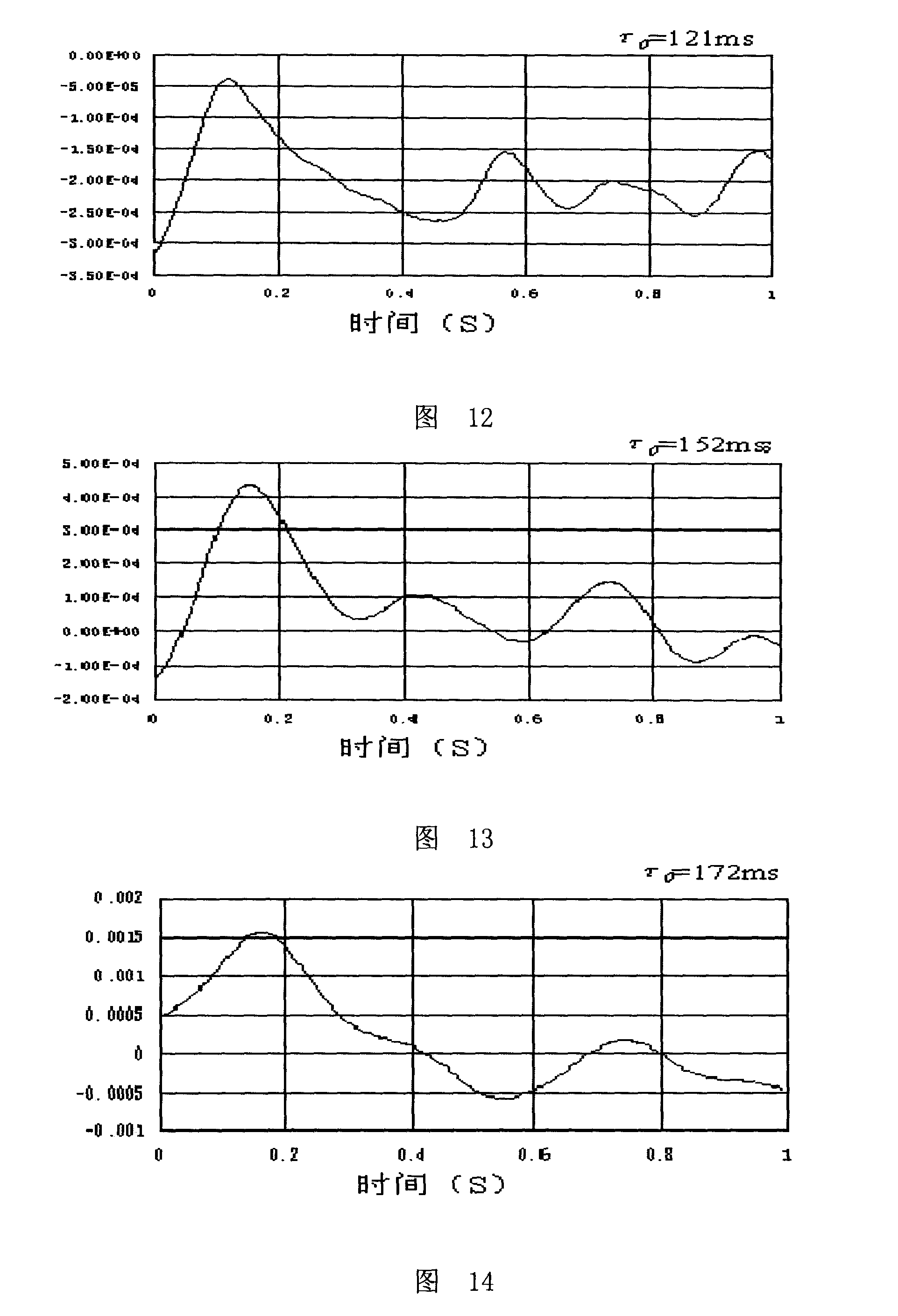

[0033] The conductance trace correlation method applied to flow measurement of injection wells described in the present invention is mainly realized by cross-correlation flow measurement technology, and the method is composed of the following steps:

[0034] Firstly, after connecting the marker solution releaser and the conductivity-type correlation flow sensor in sequence, it is set in the fluid flow channel of the injection well. The conductivity-type correlation flow sensor has six electrodes A, B, C, D, E, F, Among them, the two electrodes at the beginning and the end are excitation electrodes, externally connected to a constant current source circuit, and the four electrodes in the middle are signal acquisition electrodes, one pair of which constitutes an upstream sensor pair, and the other pair constitutes a downstream sensor pair, which are connected to two signal pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com