Dielectric ceramic, process for producing the same, and laminated ceramic capacitor

A kind of dielectric ceramic and manufacturing method, which is applied in the field of laminated ceramic capacitors to achieve the effects of stabilization, temperature characteristics, and high dielectric constant.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

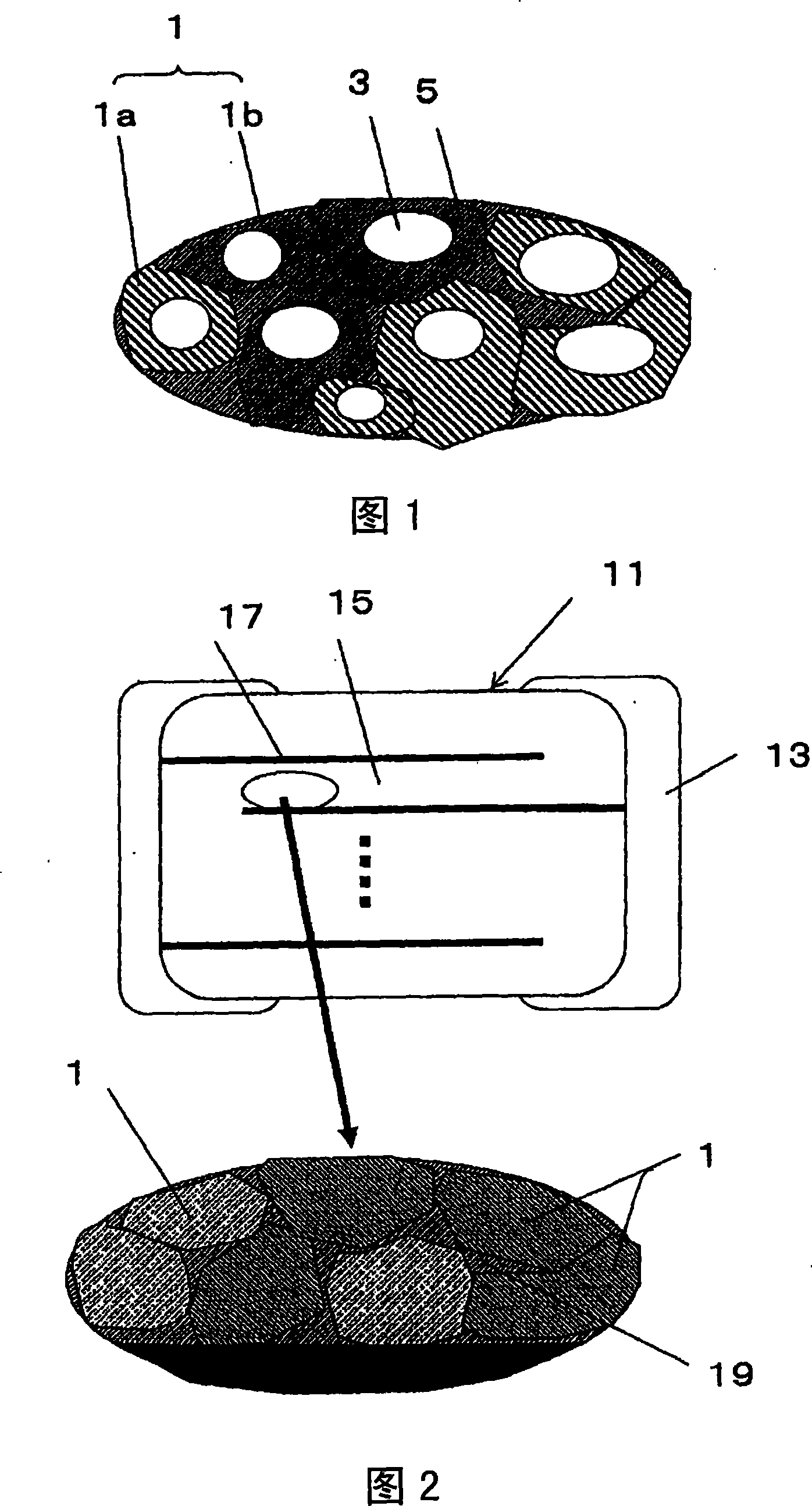

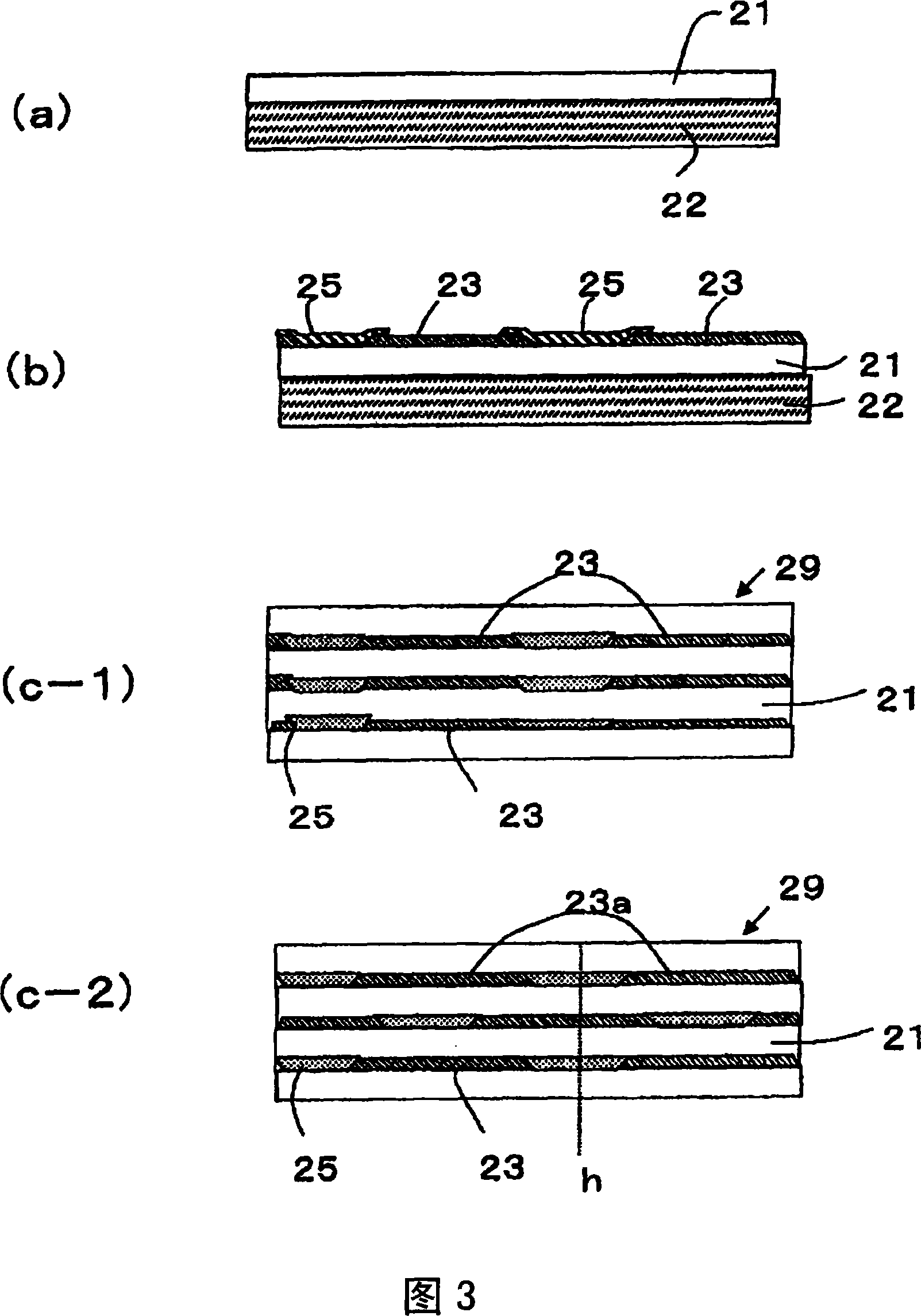

[0078] A multilayer ceramic capacitor is fabricated as shown below. Table 1 shows the types, average particle diameters, additive amounts, and firing temperatures of the raw material powders used. Here, barium titanate (BT powder) and barium-calcium titanate powder (BCT powder) were coated with Mg, Y, and Mn, and materials in which Mg, Y, and Mn were not coated were mixed with the powders. As BCT powder, Ba 0.95 Ca 0.05 TiO 3 .

[0079] The average particle diameters of barium titanate (BT powder) and barium titanate·calcium titanate powder (BCT powder) were set to 0.25 μm. When mixing the BT powder and the BCT powder, the BT powder and the BCT powder were mixed in the same molar amount, and the coating amounts of Mg, Mn, and Y were prepared so that the BT powder and the BCT powder were 100 parts by mass. In addition, BT powder and BCT powder having an A / B side ratio of 1.003 were used. In addition, the particle size of the BT powder and BCT powder used is mainly 0.2-0.4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com