Method for disinfecting air and special-purpose equipment thereof

A special equipment and air technology, applied in the direction of gasification substances, etc., can solve the problems of low gas purity, unsatisfactory effect, and unsafety, and achieve the effect of solving environmental pollution problems, ideal deodorization effect, and high level of self-control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

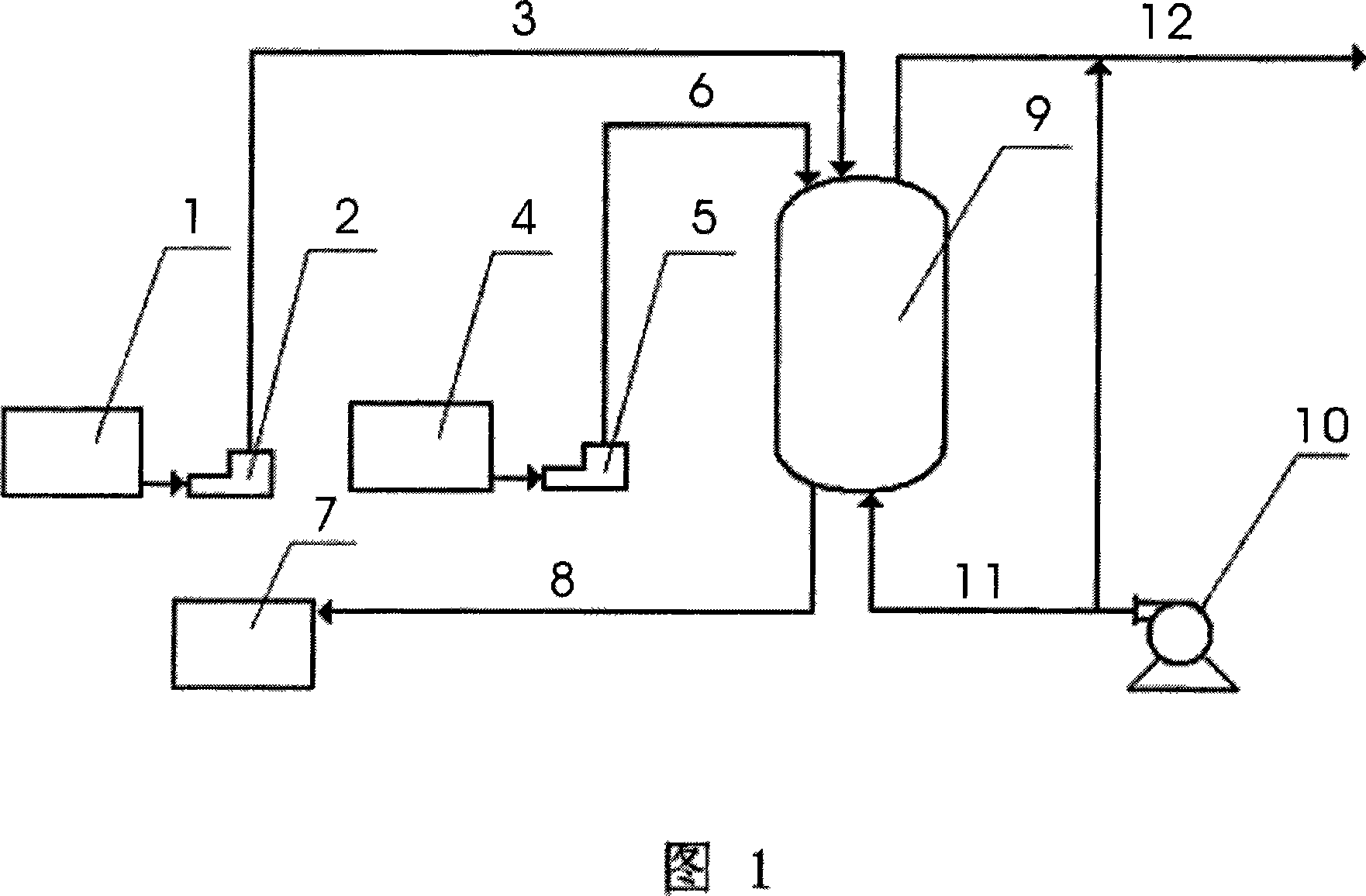

[0028] Adopt positive pressure gasification method, by metering control system (metering pump 2 and metering pump 5), the NaClO that concentration is 2.0% 2 The solution and hydrochloric acid with a concentration of 4% are added to the vaporizer 9 with a molar ratio of 1:3.87 for reaction, and the reaction temperature is controlled to be 28° C. At the same time, the compressed air is continuously delivered into the vaporizer through the air input device , the gas-liquid ratio is controlled to be 18.5:1, and the high-purity chlorine dioxide gas generated by gasification is taken out by the introduced compressed air and dilution air through the conduit 12, and discharged to a volume of 103m 3 A certain karaoke room in a certain karaoke room carries out air disinfection (the waste liquid after the separation is sent to the solution box 7 regularly, and centralized treatment is discharged). After 60 minutes of disinfection, take samples according to the following method: use FA-1 ...

Embodiment 2

[0031] Adopt positive pressure gasification method, by metering control system (metering pump 2 and metering pump 5), the NaClO that concentration is 2.5% 2 The solution and dilute hydrochloric acid with a concentration of 6% are added to the vaporizer 9 with a molar ratio of 1:3.5 for reaction, and the reaction temperature is controlled to be 26° C. At the same time, compressed air is continuously delivered into the vaporizer through the air input device , the gas-liquid ratio is controlled to be 23.0:1, and the high-purity chlorine dioxide gas generated by gasification is taken out by the introduced compressed air and dilution air through the conduit 12, and discharged to a volume of 30m 3 A certain factory employee dormitory in the company carries out air disinfection (the waste liquid after separation in the gasifier is regularly sent to the solution box 7 for centralized treatment and discharge), and the disinfection is sampled after 60 minutes (sampling method is the same...

Embodiment 3

[0034] Adopt positive pressure gasification method, by metering control system (metering pump 2 and metering pump 5), the NaClO that concentration is 1.8% 2 The solution and the hydrochloric acid with a concentration of 4% are added to the vaporizer 9 with a molar ratio of 1: 3.93 for reaction, and the reaction temperature is 26° C. Meanwhile, the compressed air is continuously delivered into the vaporizer through the air input device, and the control The gas-liquid ratio is 17.6:1, and the high-purity chlorine dioxide gas generated by gasification is taken out through the conduit 12 by the introduced compressed air and dilution air, and discharged to a volume of about 300m 3 The fever clinic of a certain hospital carried out air disinfection (the waste liquid after separation in the gasifier was regularly sent to the solution box 7 for centralized treatment and discharge), and sampling was performed after 60 minutes of disinfection (the sampling method was the same as in Examp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com