Passive microfluid mixer and packaging method thereof

An encapsulation method and microfluidic technology, applied in fluid mixers, chemical instruments and methods, mixers, etc., can solve problems such as difficult cleaning of PDMS microfluidic chips, and achieve the effect of improving the mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

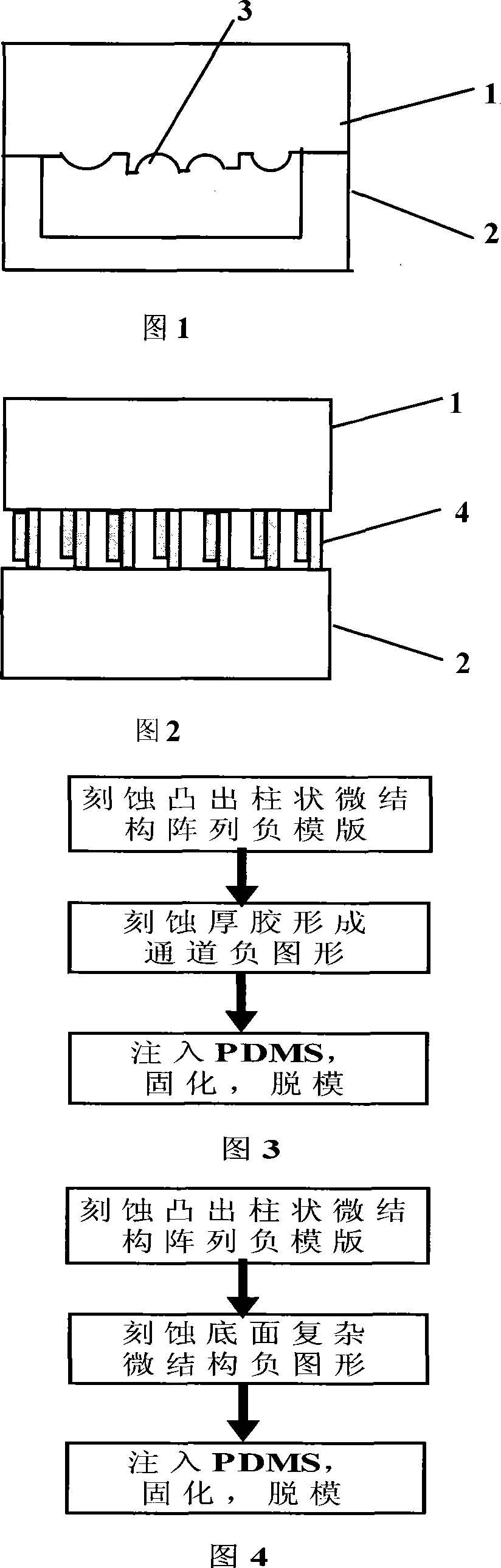

[0019] Fabrication method of the lower PDMS layer:

[0020] See Figure 3 and Figure 5, its main process:

[0021] 1. Coating photoresist on the silicon wafer, developing, and curing to obtain a protruding columnar microstructure adhesion array pattern, and then inductively coupled plasma (ICP) etching the silicon wafer to obtain a silicon template negative pattern a;

[0022] 2. Apply thick glue such as SU8 glue on the silicon wafer, and etch to obtain the negative pattern b of the fluid channel groove;

[0023] 3. Inject PDMS, degas and penetrate into the hole under vacuum, heat and solidify c;

[0024] 4. Mechanical demoulding to obtain the lower PDMS layer.

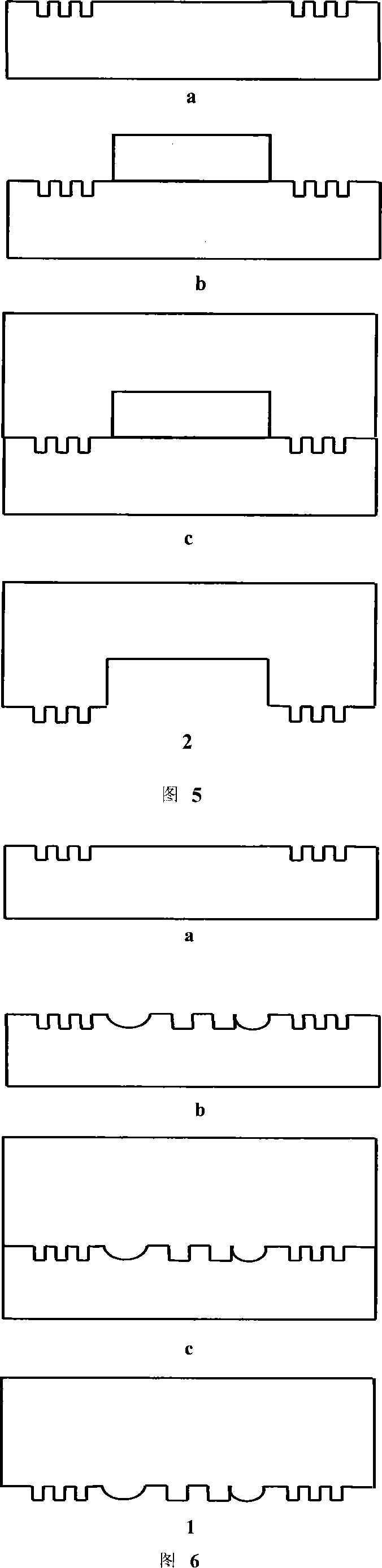

[0025] Fabrication method of the upper PDMS layer:

[0026] See Figure 4 and Figure 6, the main process:

[0027] 1. Coating photoresist on the silicon wafer, developing, and curing to obtain a protruding columnar microstructure adhesion array pattern, and then inductively coupled plasma (ICP) etching the silicon w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com