Active transition liquid phase diffusion welding technique of metal-matrix composite material

A composite material, metal-based technology, used in metal processing equipment, welding/cutting media/materials, welding media, etc., can solve problems such as low performance of joints, poor wettability of ceramic reinforced phase/metal interface, and weak bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

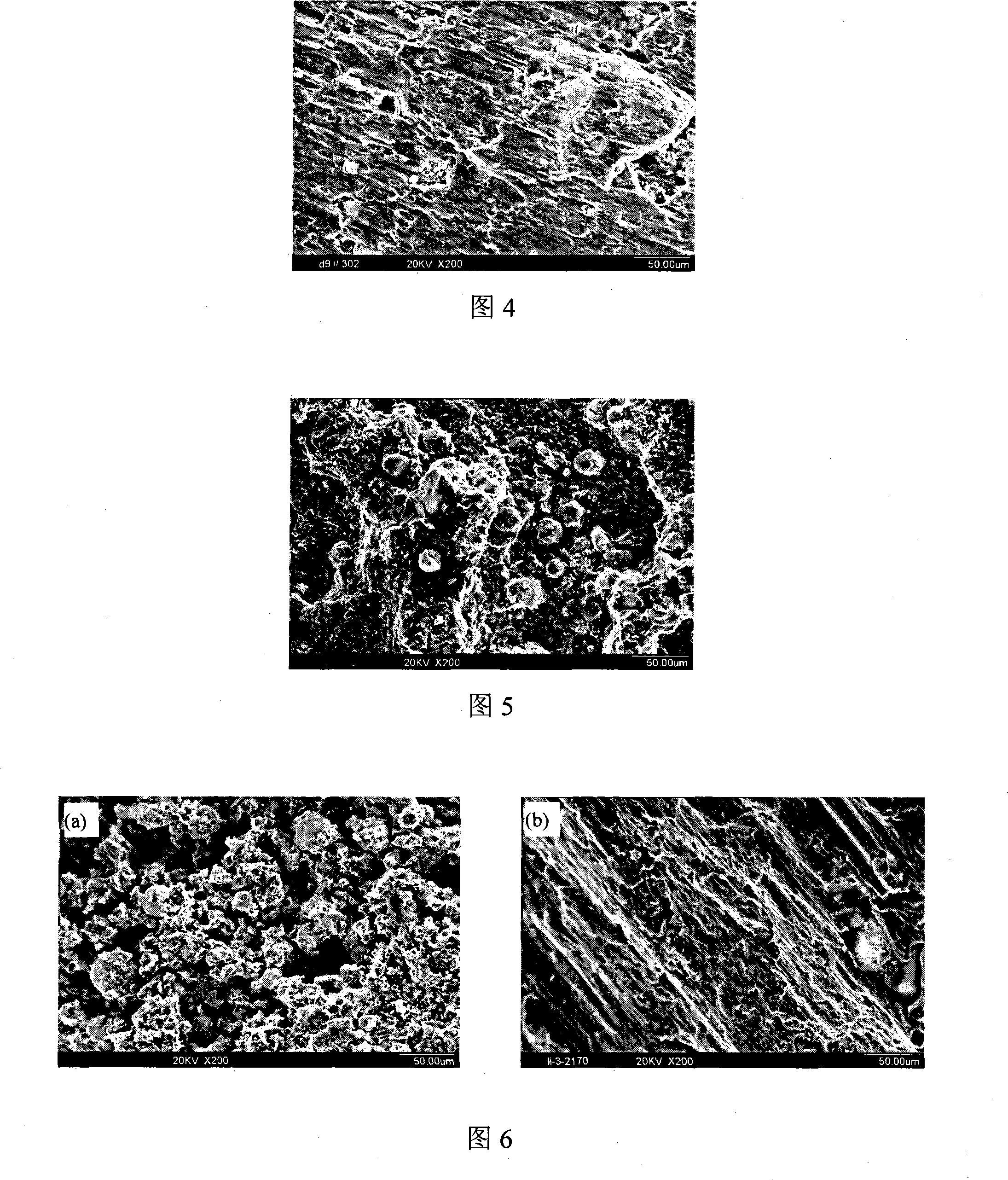

[0041] The basic idea of the technical solution of the present invention can be summarized as follows: firstly, aiming at the serious defects of the guiding ideology of the traditional interlayer alloy system design, the following new "intermediate layer alloy system design principle method" is created: the interlayer is required to remove melting and de-melting In addition to the elements, active elements that can react with the ceramic reinforcement must be added at the same time to obtain an "active intermediate layer". Then, on the basis of creating the above-mentioned "principle method for the design of the active interlayer alloy system", and further by limiting the "welding temperature" and "liquid phase acquisition method", a new process for composite material welding is completely established—" Active-Transient Liquid Phase Bonding (A-TLP bonding) process.

[0042] Concrete content of the present invention is introduced as follows:

[0043] (1) Design principles of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com