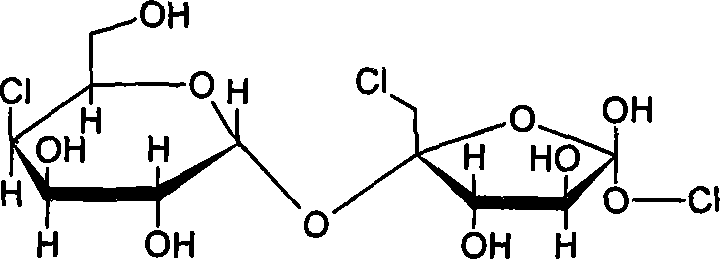

Chlorination method for trichlorosucrose preparation

A technology of sucralose and chlorinating reagents, applied in chemical instruments and methods, sugar derivatives, sugar derivatives, etc., can solve the problems of reducing sweetness compounds, complex synthesis processes, etc., achieving easy operation control, broad development and Application prospect and effect of energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

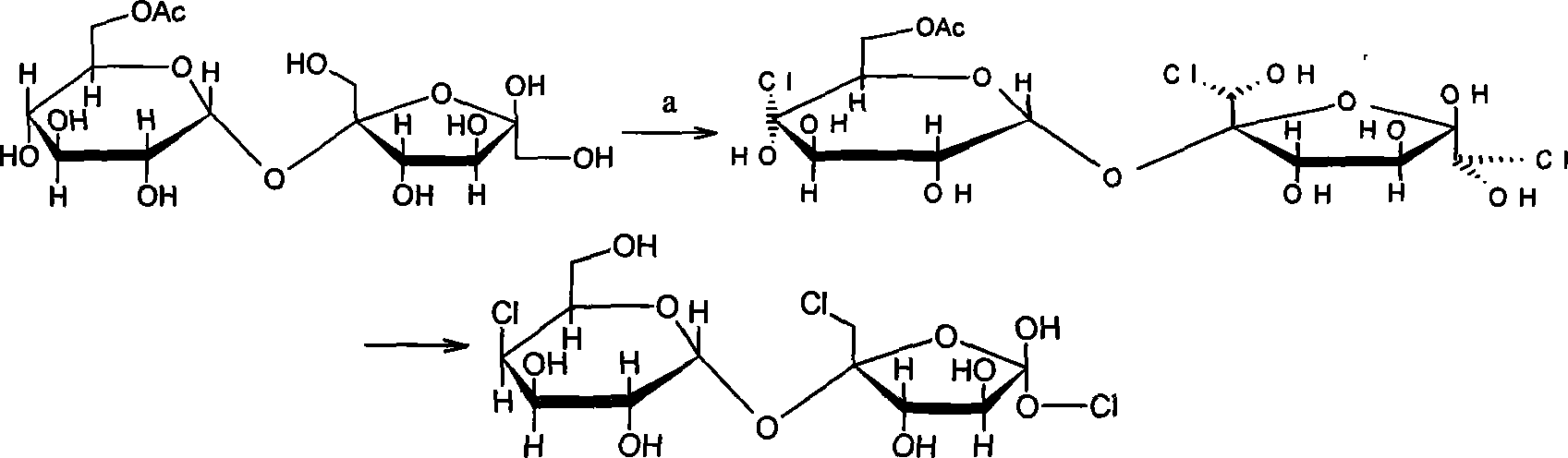

Method used

Image

Examples

Embodiment 1

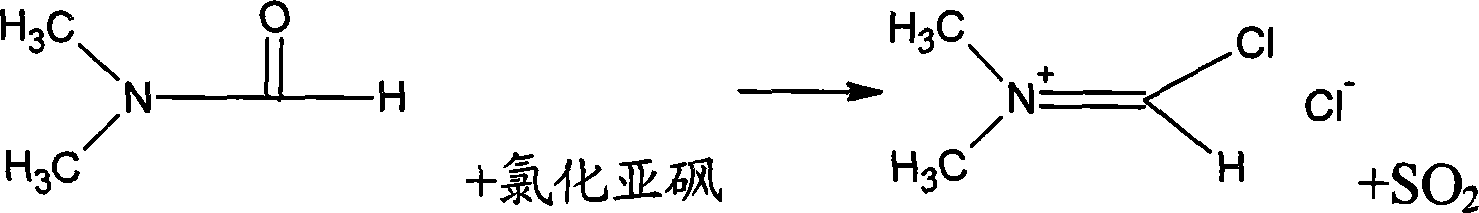

[0046] A method for chlorination in the preparation of sucralose, the process steps are as follows:

[0047] 1. At room temperature, put 600ml of N,N-dimethylformamide in a 2000ml reaction vessel, slowly add 180ml of thionyl chloride under normal temperature stirring conditions, the temperature is not easy to rise too fast, a better method is to put it under the reaction vessel (Natural) water, after the dropwise addition is completed, stir for 1-2 hours, then slowly add 300 grams (100 grams of equivalent sugar) sucrose-6-acetate dropwise under normal temperature conditions, heat up immediately after the end, and 80°C, 100°C, 113°C for 1 hour, 1.5 hours, 2-2.5 hours respectively, and should not exceed 115°C;

[0048] 2. After the segmental heating is completed, stir and cool to room temperature, add about 600 grams of 31% concentrated NaOH solution dropwise at room temperature until the pH is about 9, stir for about half an hour and reverse the adjustment of about 70 grams of ...

Embodiment 2

[0052] A method for chlorination in the preparation of sucralose, the process steps are as follows:

[0053] 1. At room temperature, put 700ml of N,N-dimethylformamide in a 2000ml reaction vessel, slowly add 180ml of thionyl chloride under normal temperature stirring conditions, the temperature is not easy to rise too fast, a better method is to put it under the reaction vessel (Natural) water, after the dropwise addition is completed, stir for 1-2 hours, then slowly add 300 grams (100 grams of equivalent sugar) sucrose-6-acetate dropwise under normal temperature conditions, heat up immediately after the end, and 80°C, 100°C, 113°C for 1 hour, 1.5 hours, 2-2.5 hours respectively, and should not exceed 115°C;

[0054] 2. After the segmental heating is completed, stir and cool to room temperature, and add about 750 grams of 31% concentrated NaCO dropwise at room temperature. 3 Solution until the pH is about 9, stir for about half an hour and reverse 70 grams of 32% concentrated...

Embodiment 3

[0058] A method for chlorination in the preparation of sucralose, the process steps are as follows:

[0059]1. At room temperature, put 900ml of N,N-dimethylformamide in a 2000ml reaction vessel, slowly add 180ml of thionyl chloride under normal temperature stirring conditions, the temperature is not easy to rise too fast, a better method is to put it under the reaction vessel (Natural) water, after the dropwise addition is completed, stir for 1-2 hours, then slowly add 300 grams (100 grams of equivalent sugar) sucrose-6-acetate dropwise under normal temperature conditions, heat up immediately after the end, and 80°C, 100°C, and 113°C for 1 hour, 1.5 hours, and 2-2.5 hours respectively, and should not exceed 115°C;

[0060] 2. After the segmental heating is completed, stir and cool to room temperature, add about 255 grams of 31% concentrated ammonia water dropwise at room temperature until the pH is about 9, and stir for about half an hour to reverse adjust about 70 grams of 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com