Prefabricated prestressing pipe pile composite supporting wall structure

A technology of prestressed pipe piles and composite support, which is applied in the direction of sheet pile walls, underwater structures, foundation structure engineering, etc., can solve the problems such as the inflexible adjustment of the strength and stiffness of the support wall panels, and achieve the support effect Good, reliable pile body quality, strong deformation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

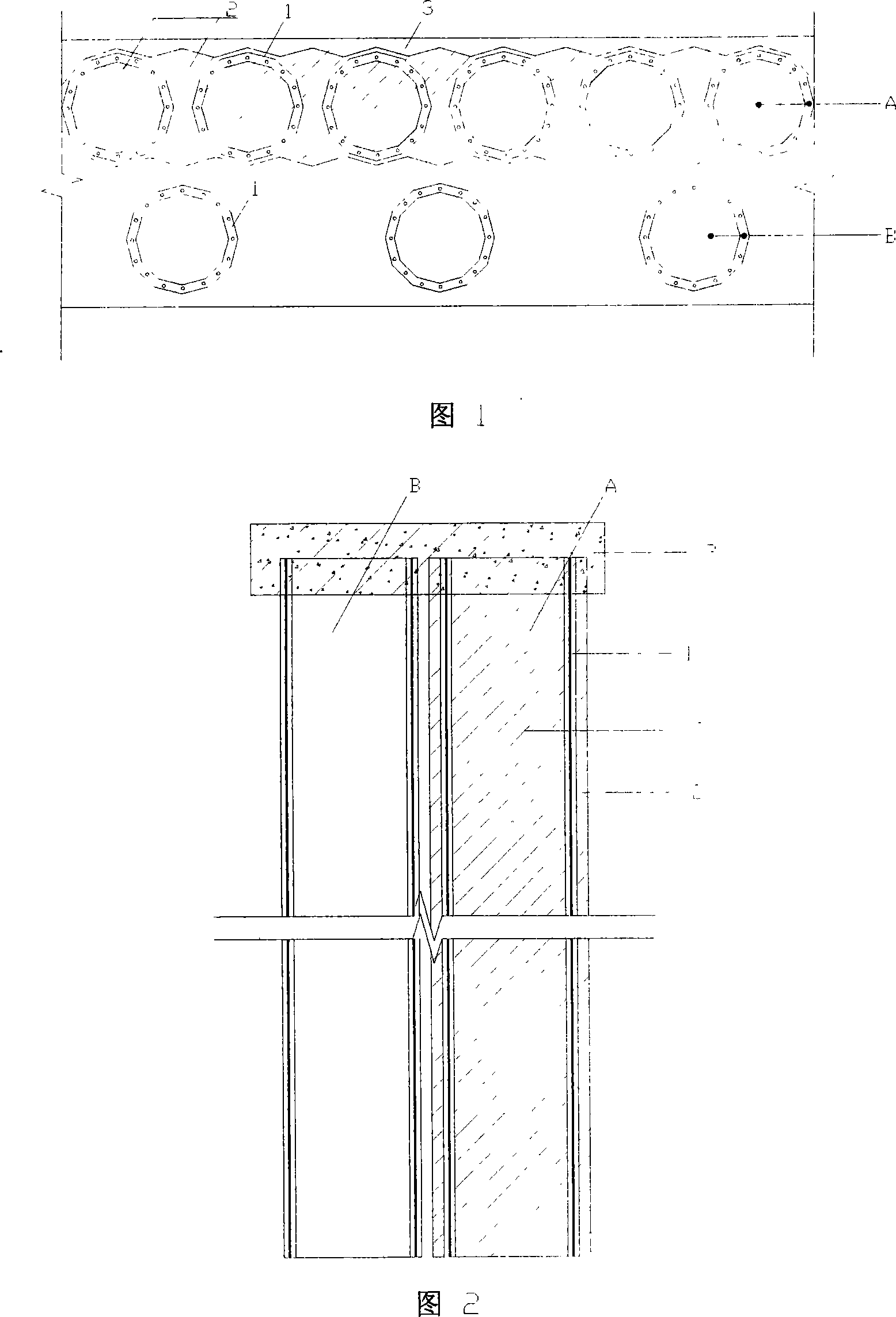

[0013] The prefabricated prestressed pipe pile composite support wall structure of the present utility model comprises a prefabricated prestressed pipe pile 1 and a stirring body 2; The prestressed pipe piles 1 are connected as a whole to form the composite support wall panel A in the front row, and there is a strength adjustment support B on the outside of the composite support wall A, and the strength adjustment support B includes the prefabricated prestressed pipe pile 1 and the prefabricated prestressed Stirring body 2 in stress pipe pile 1 is composed, composite support wall A and strength adjustment support B are connected through cover beam 3 . The mixing body material is formed by mixing cement, expansive soil, fly ash and soil.

[0014] The excavation depth of the foundation pit is 9.8m, and the prefabricated prestressed pipe pile composite support wall structure is used for foundation pit support. The outer diameter of the pipe pile is 600mm. The net spacing of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com