Self-adapting solar energy heat collection molten salt receiver system

A solar heat collection and receiver technology, applied in the field of solar energy applications, can solve the problems of heat collection differences of receiver modules, different molten salt temperatures, and inability to effectively adapt to changes in working conditions, so as to improve work efficiency and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

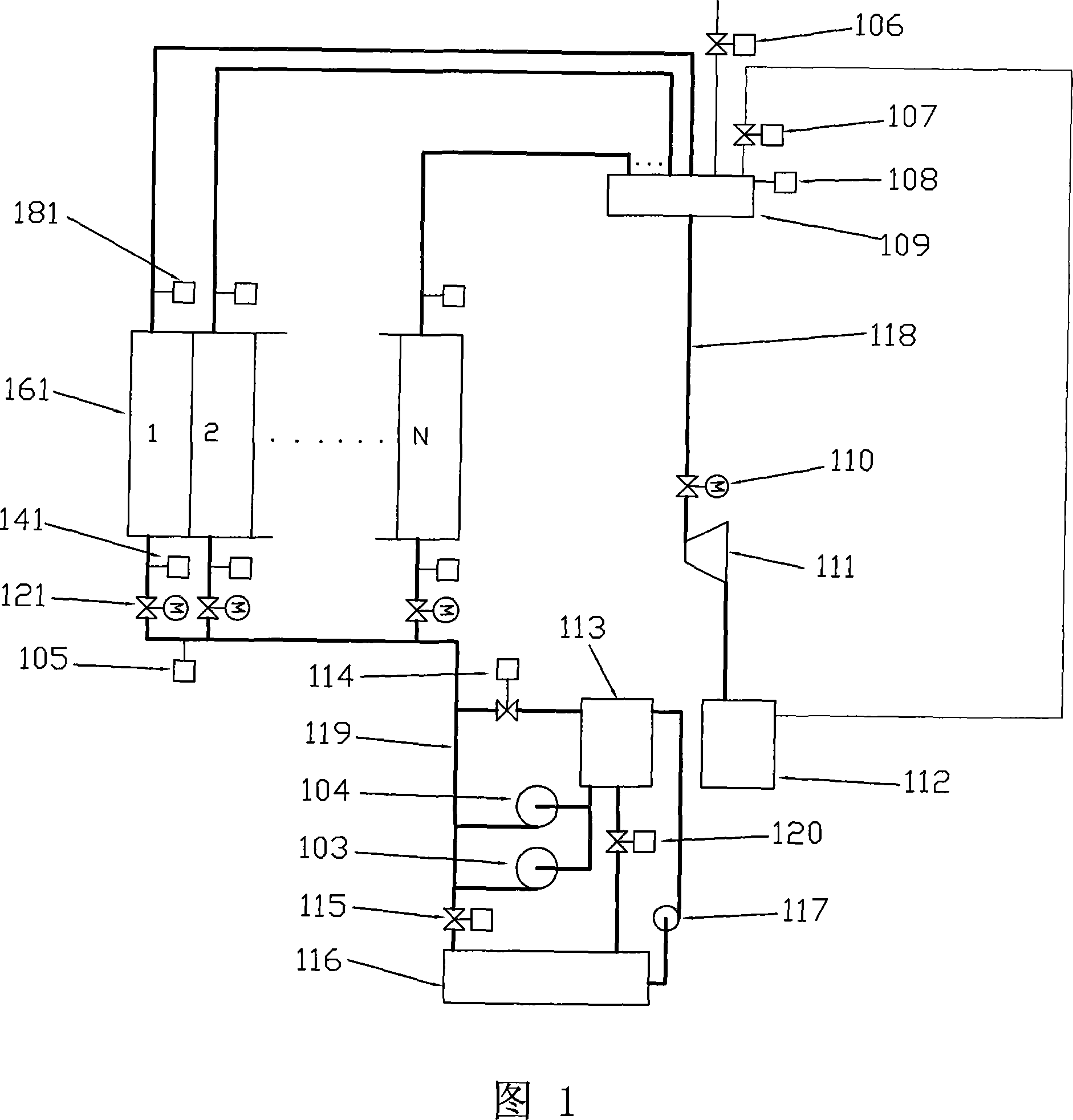

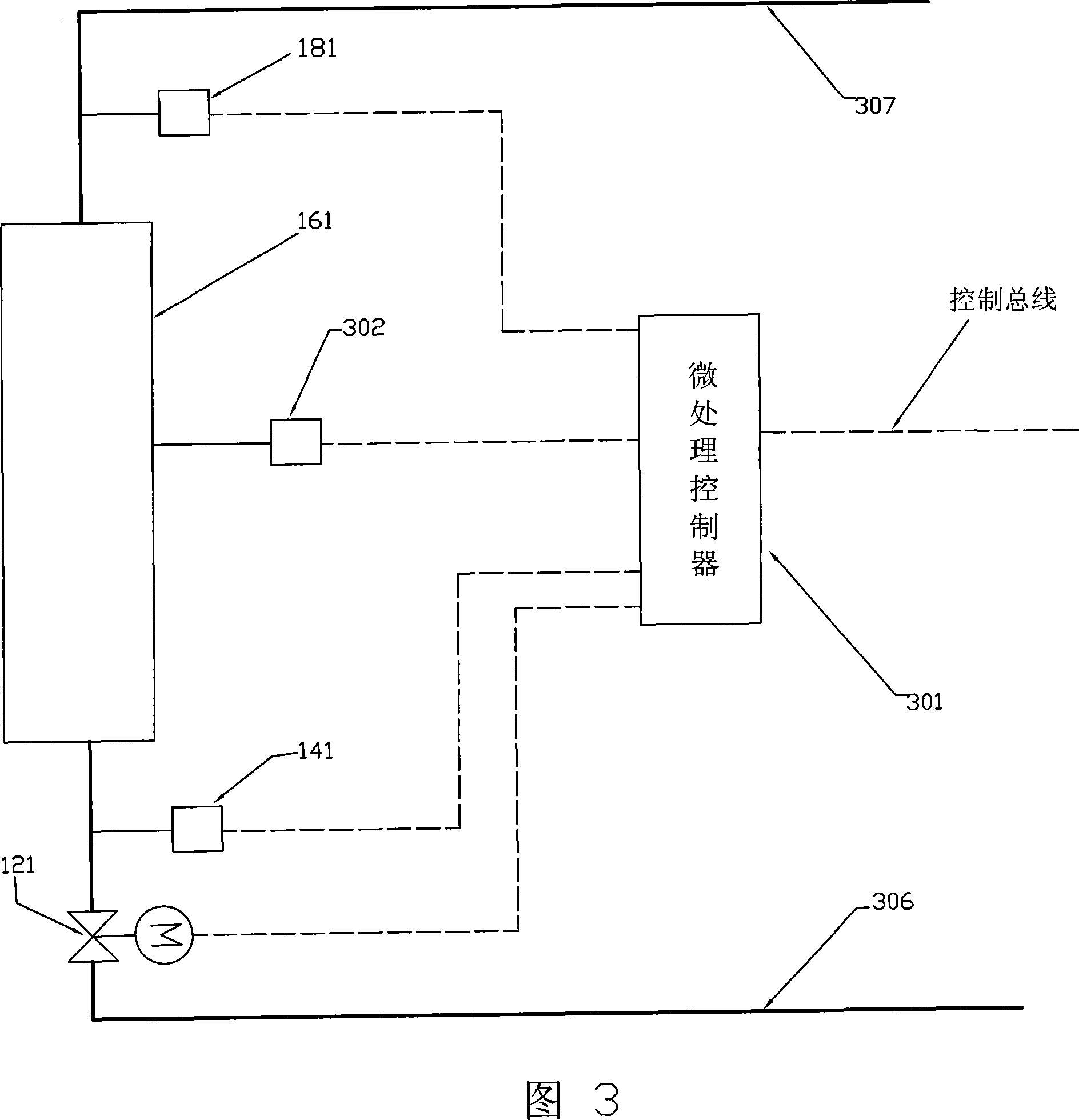

[0023] As a preferred embodiment, as shown in Figure 1, the present invention includes: a cold molten salt storage tank 113, an emergency tank 116, a set of fault-tolerant molten salt pump delivery system, composed of a plurality of adaptive receivers A central receiver consisting of modules 161 (1, 2...N), a hot molten salt buffer tank 109 with a molten salt level sensor 108, a flow regulating valve 110, a turbine capable of recycling the potential energy of the hot molten salt 111 and a hot molten salt storage tank 112 that can provide hot molten salt for the molten salt power generation system.

[0024]As shown in Figure 1, the cold molten salt storage tank 113 provides the cold molten salt required by the system, and delivery pumps 103 and 104 deliver the cold molten salt from the cold molten salt storage tank 113 to the receiving tower (not shown) top. On the central receiver, the central receiver is composed of a plurality of receiver modules 161 (1, 2...N) facing differ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com