Aluminium alloy resistance spot welding nugget size real-time detection process

A technology of nugget diameter and resistance spot welding, applied in measuring devices, physical realization, biological neural network models, etc., can solve problems such as real-time detection of difficult spot welding sites, achieve fast data transmission speed, high accuracy, and simple algorithms Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the embodiments and drawings:

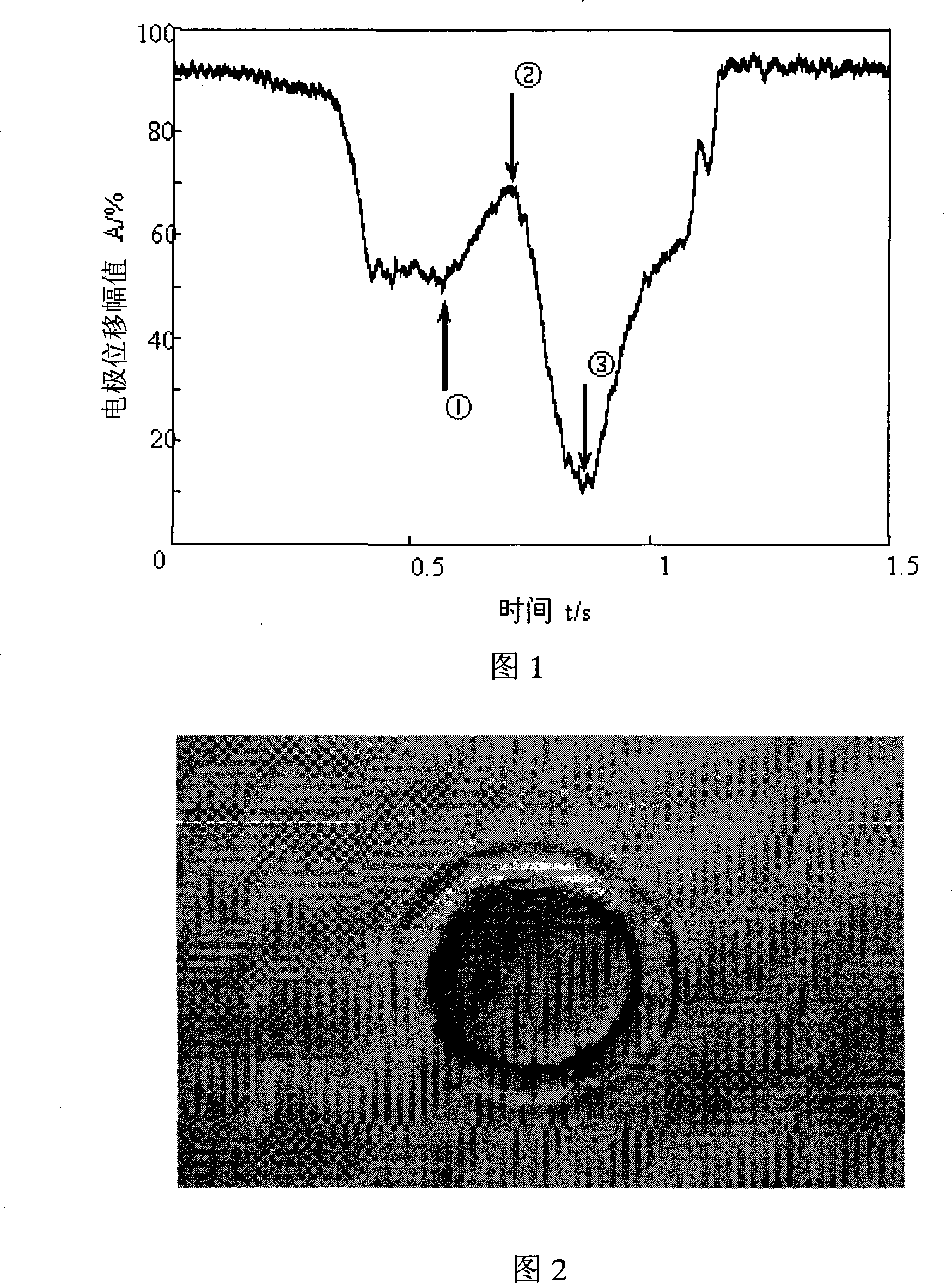

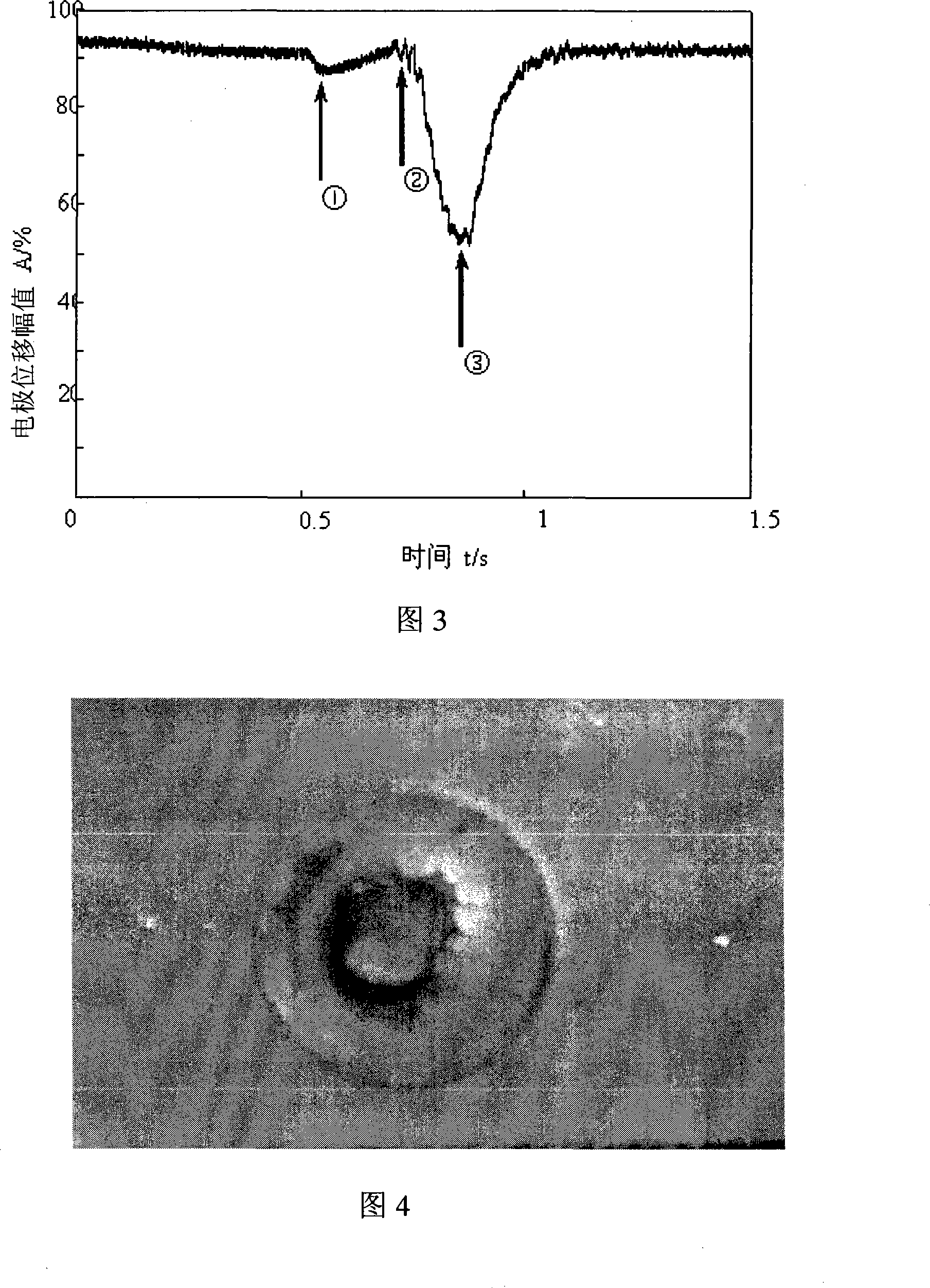

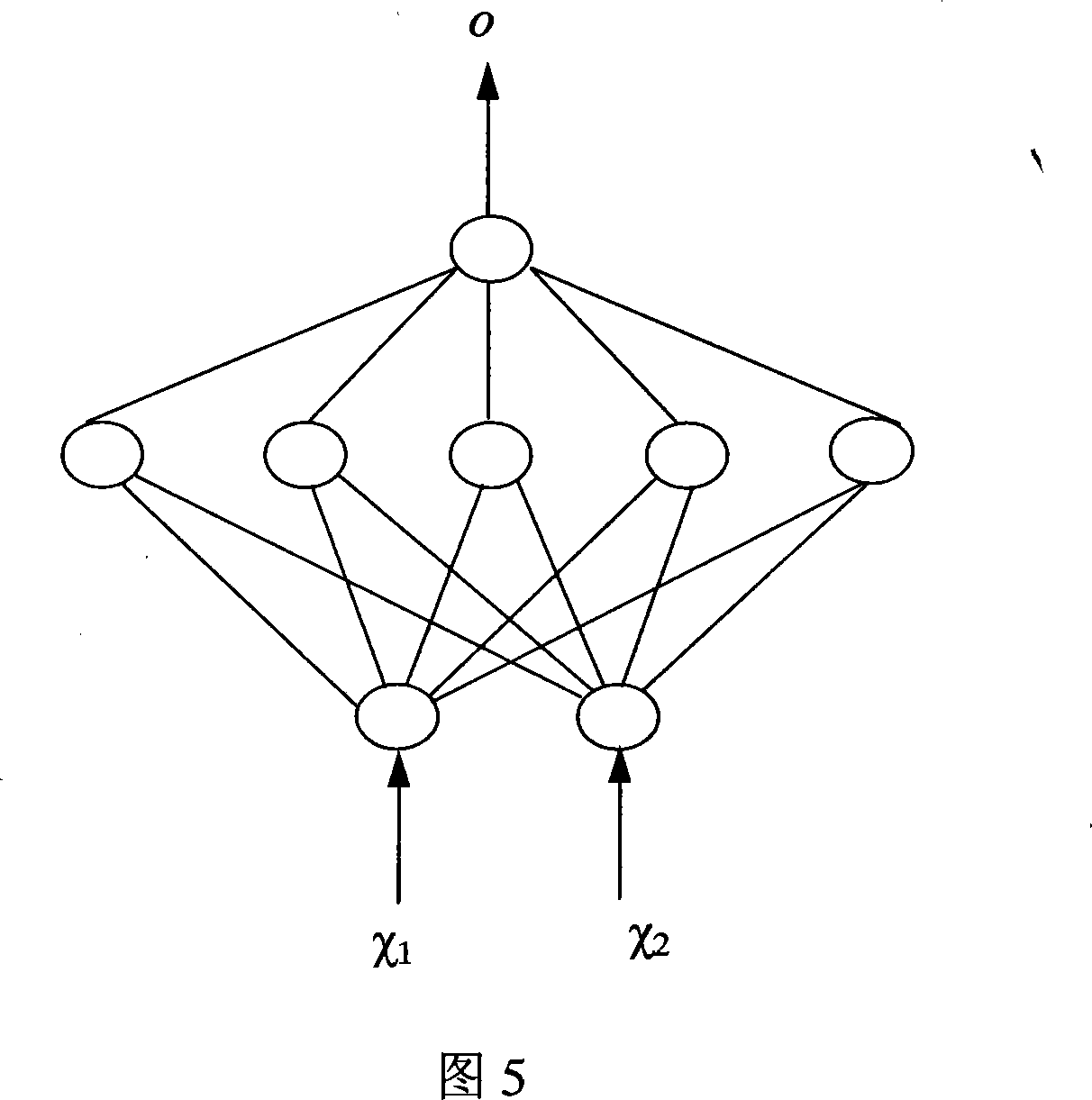

[0022] A method for real-time detection of aluminum alloy resistance spot welding nugget diameter (hereinafter referred to as nugget diameter) (hereinafter referred to as the method, see Figures 1-5) designed in the present invention includes the following steps:

[0023] 1. Collect the electrode displacement signal process parameters in the resistance spot welding process of the aluminum alloy test plate (hereinafter referred to as the spot welding process), and draw the electrode displacement signal curve diagram (see Figures 1 and 3 of the embodiment). The method of the present invention only needs to collect one signal of electrode displacement in the resistance spot welding process. Compared with the four signals of electrode voltage, current, electrode displacement and sound that need to be collected in the prior art, it has obvious advantages of simple process,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com