Heating element and device for heating article

A technology of heating device and heating body, which is applied in the directions of heating device, lighting and heating equipment, packaging, etc., can solve the problem of not considering the water permeability of the inner bag, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

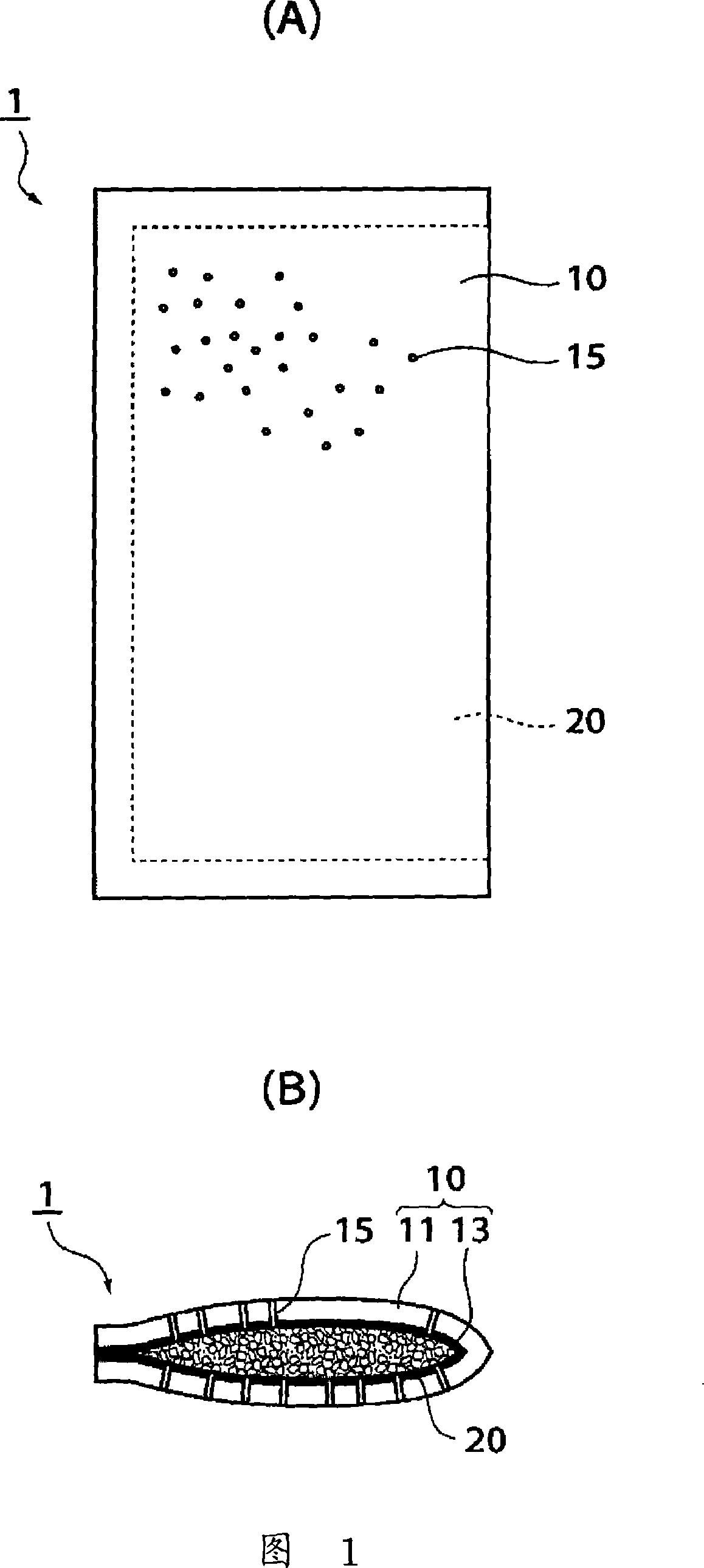

[0117] FIG. 1 is a diagram illustrating the structure of a heat generating body according to an embodiment of the present invention, FIG. 1(A) is a plan view, and FIG. 1(B) is a cross-sectional view.

[0118] The heating element 1 includes a bag body 10 and a heating agent 20 packed into the bag body 10 .

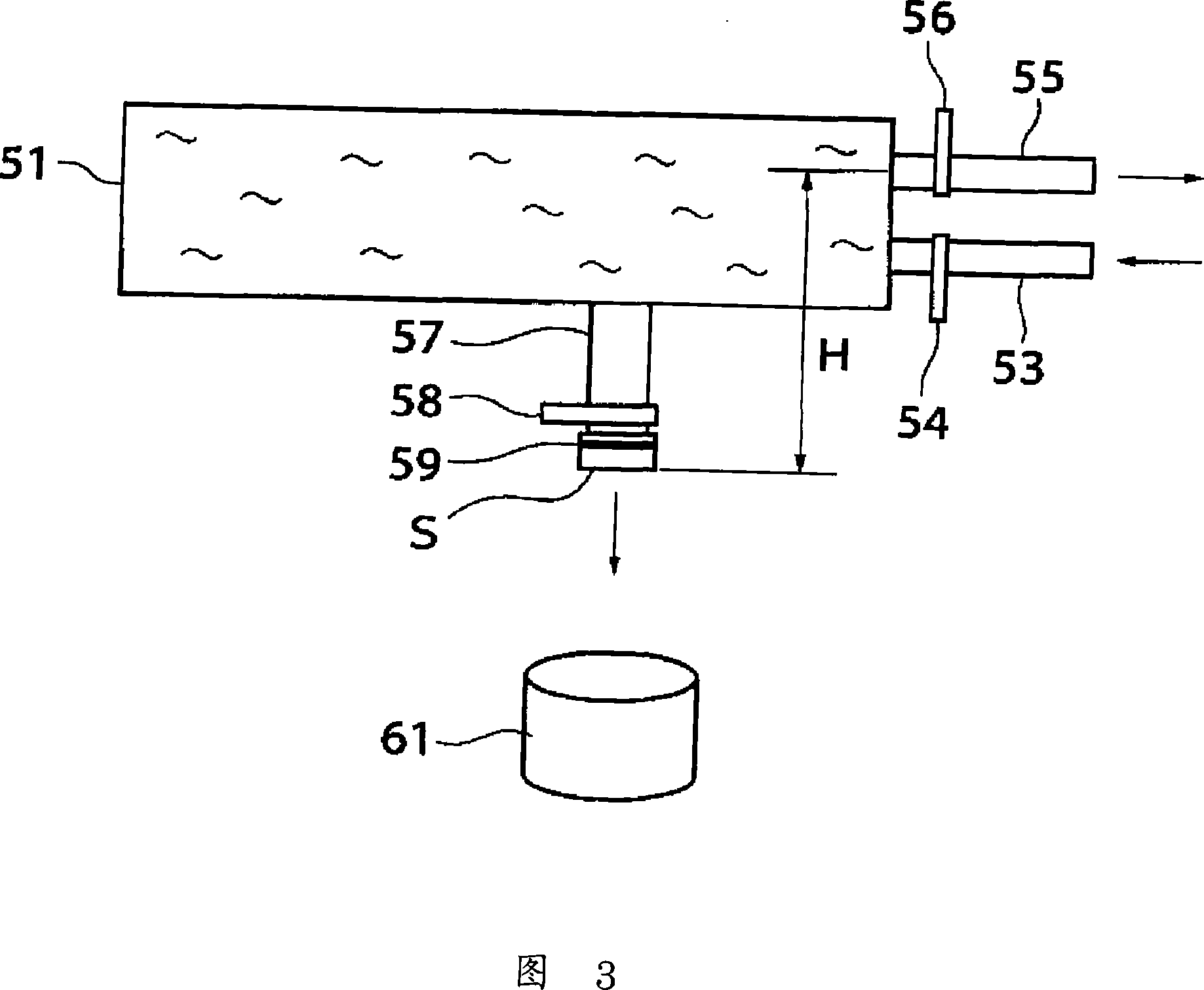

[0119] The bag body 10 is a cotton nonwoven fabric 11 (CO40s / PP40, manufactured by UNITIKA), and a waterproof layer 13 (PP) is provided on the inner surface thereof. The pinholes 15 are formed at approximately the same density on the entire surface of the bag body 10 . The diameter of the pinhole 15 is 0.2-0.4 mm. The water permeability rate of the bag body 10 measured by the measuring method described above (refer to FIG. 3 ) is 100 ml / min / cm 2 . In addition, this value can be converted from the ventilation rate measured by the Gurley-type air permeability tester. The size of the bag body 10 is 90mm×155mm.

[0120] The exothermic agent 20 is a mixed powder obtained by...

Embodiment 2

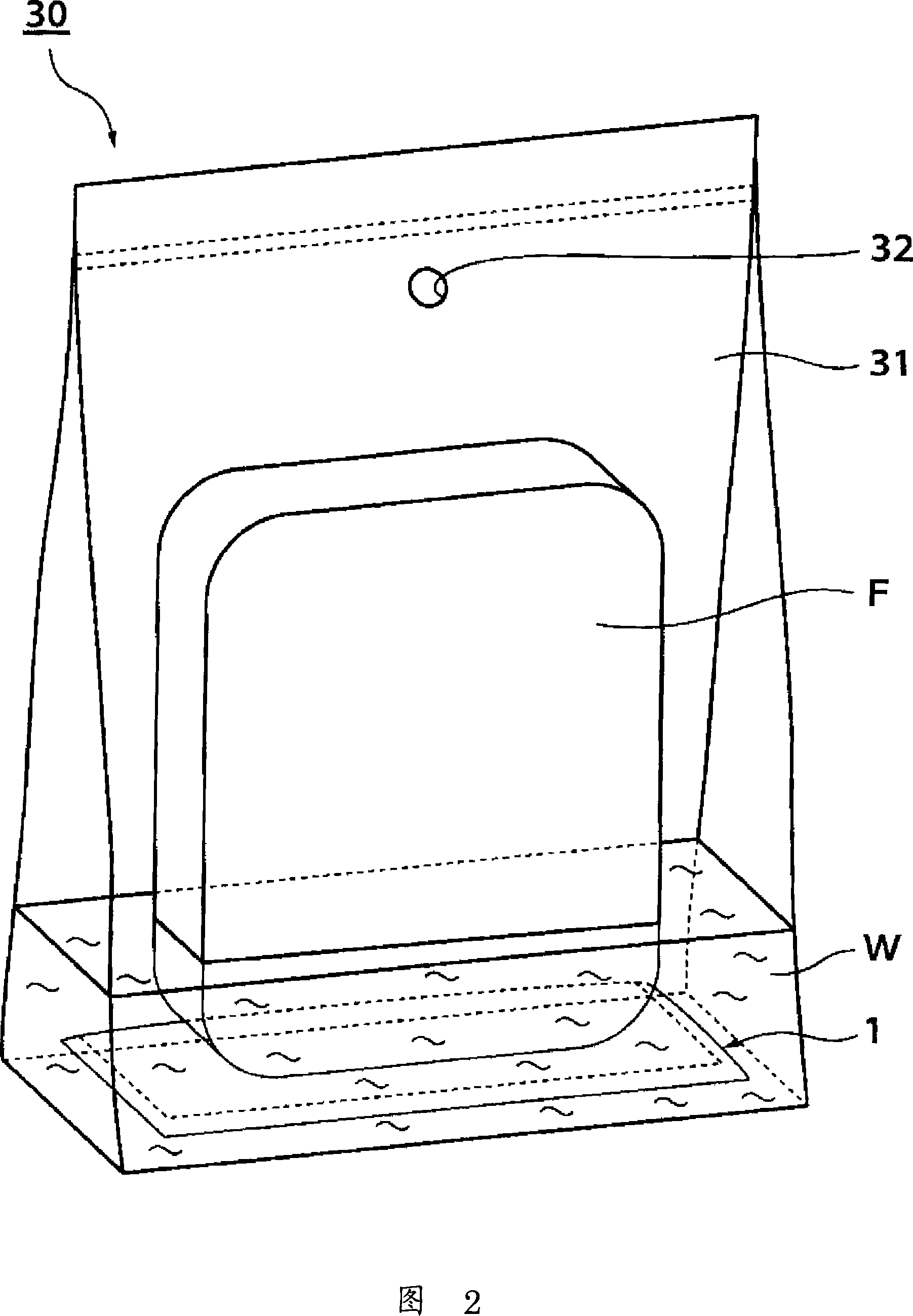

[0122] Fig. 2 is a diagram showing an article heating device according to a first embodiment of the present invention. This example shows an apparatus for heating retort-packed rice.

[0123] The article heating device 30 includes a heating bag (container) 31 having an exhaust port 32 , a heating element 1 shown in FIG. 1 , and water W for reaction. In this example, two circular exhaust ports 32 with a diameter of 5 mm are provided. 2 to 4 holes with a diameter of 3 to 7 mm can be set as the exhaust port 32 . In addition, 1 to 2 holes with a diameter of 10 to 15 mm, or 8 to 10 holes with a diameter of 1 to 2 mm may be provided according to the container. In addition, the shape of the exhaust port does not need to be circular, as long as it is a shape that allows water vapor and hydrogen to escape.

[0124] In addition, in order to prevent the heating element 1 from reacting with moisture in the air, the heating element 1 is placed in an airtight outer bag during storage.

...

Embodiment 3

[0128] 8 is a diagram illustrating an article heating device according to a second embodiment of the present invention, FIG. 8(A) is a perspective view of the entire heating device, and FIG. 8(B) is a front sectional view. This example shows a device for heating disposable paper towels.

[0129] The article heating device 40 includes a heating box (container) 41, a heating element 1, and water W for reaction. In addition, in order to prevent the heating element 1 from reacting with moisture in the air, the heating element 1 is placed in an airtight outer bag during storage.

[0130] The heat generating body 1 is composed of the same bag as in Example 1 and a heat generating agent contained in the bag. The bag body is made of cotton non-woven fabric of the same material as in Example 1. In this example, the dimensions of the bag are 50 mm x 110 mm.

[0131] The exothermic agent is a mixed powder (10 g in total) in which 5 g of quicklime powder (manufactured by Tangen Lime Co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com