Low-temperature refrigeration device for recycling oil gas

A refrigeration device and low-temperature technology, applied in steam/steam condensers, steam condensation, chemical instruments and methods, etc., can solve problems such as energy waste and unsafety, reduce costs, reduce installed capacity, and improve energy utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

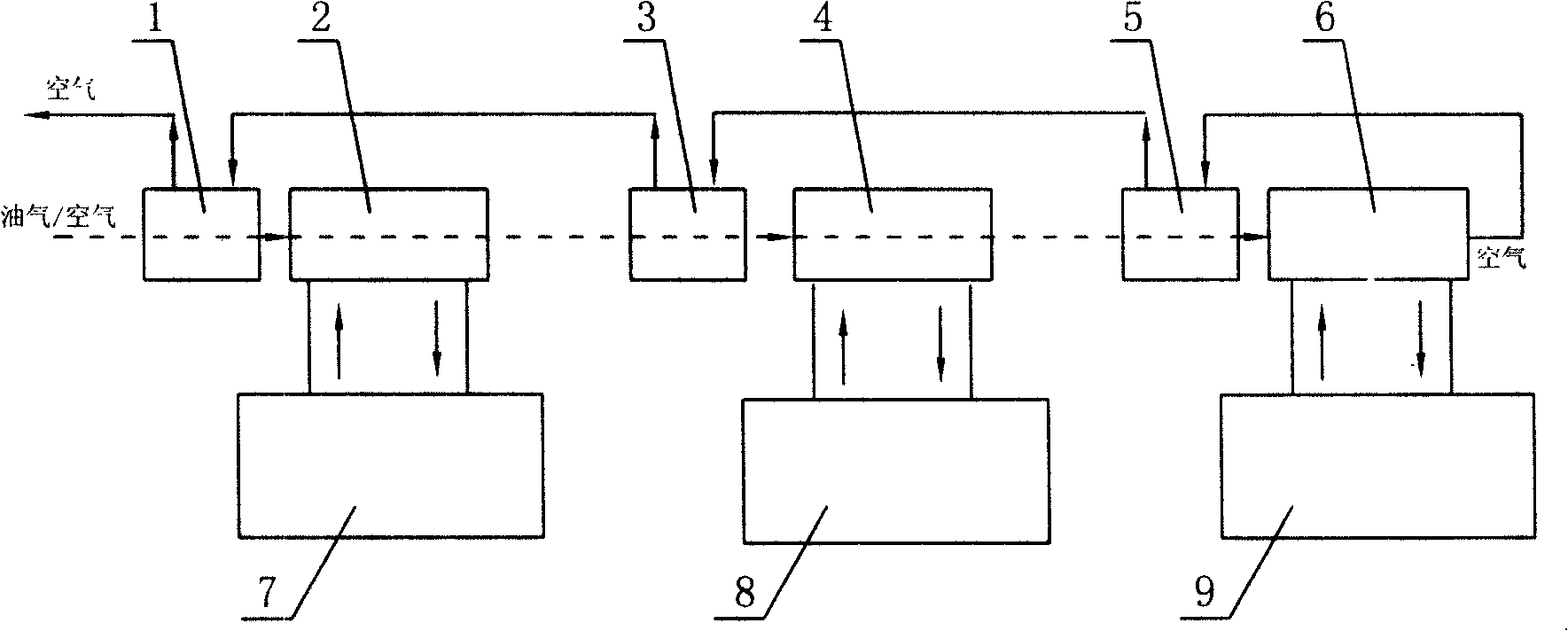

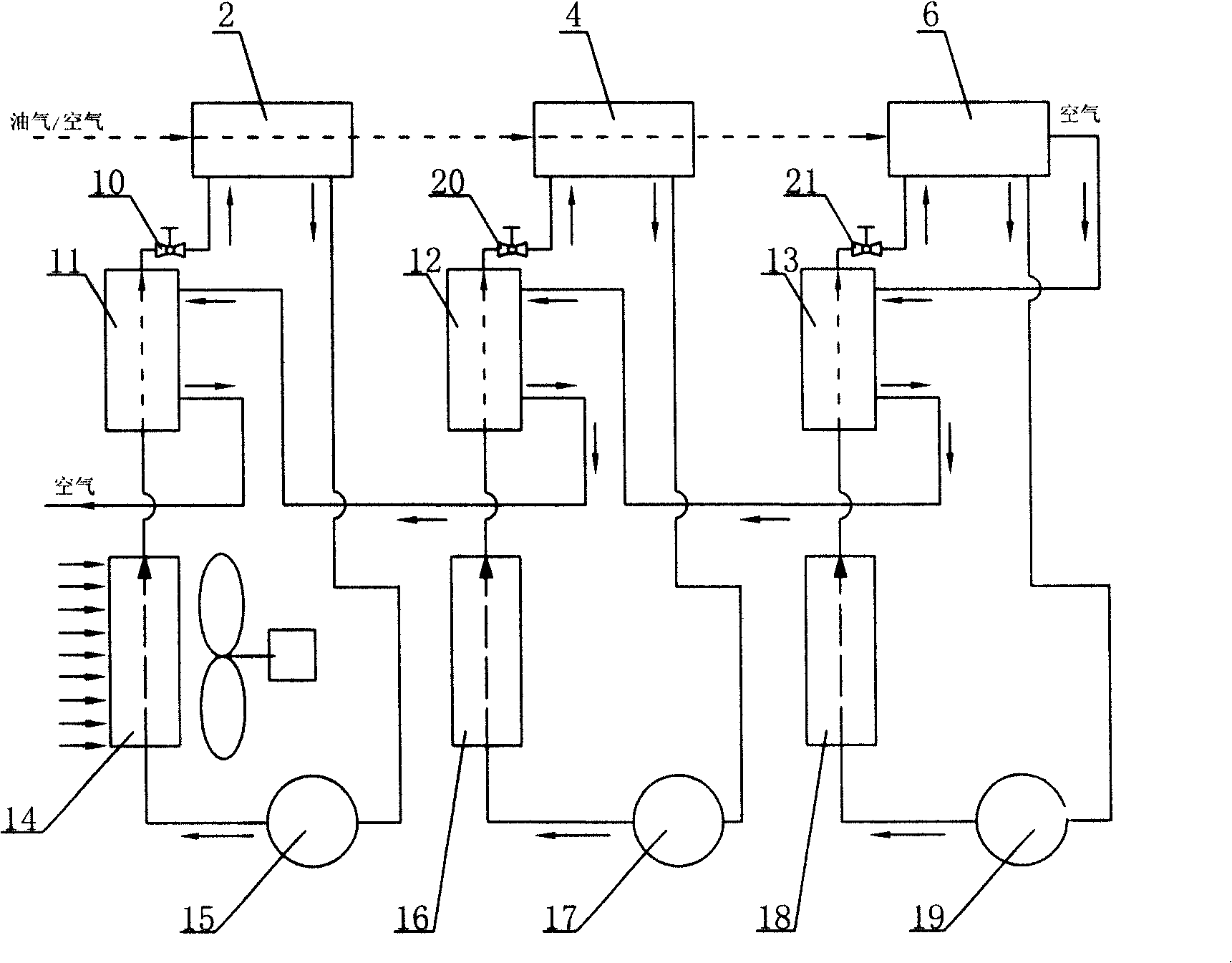

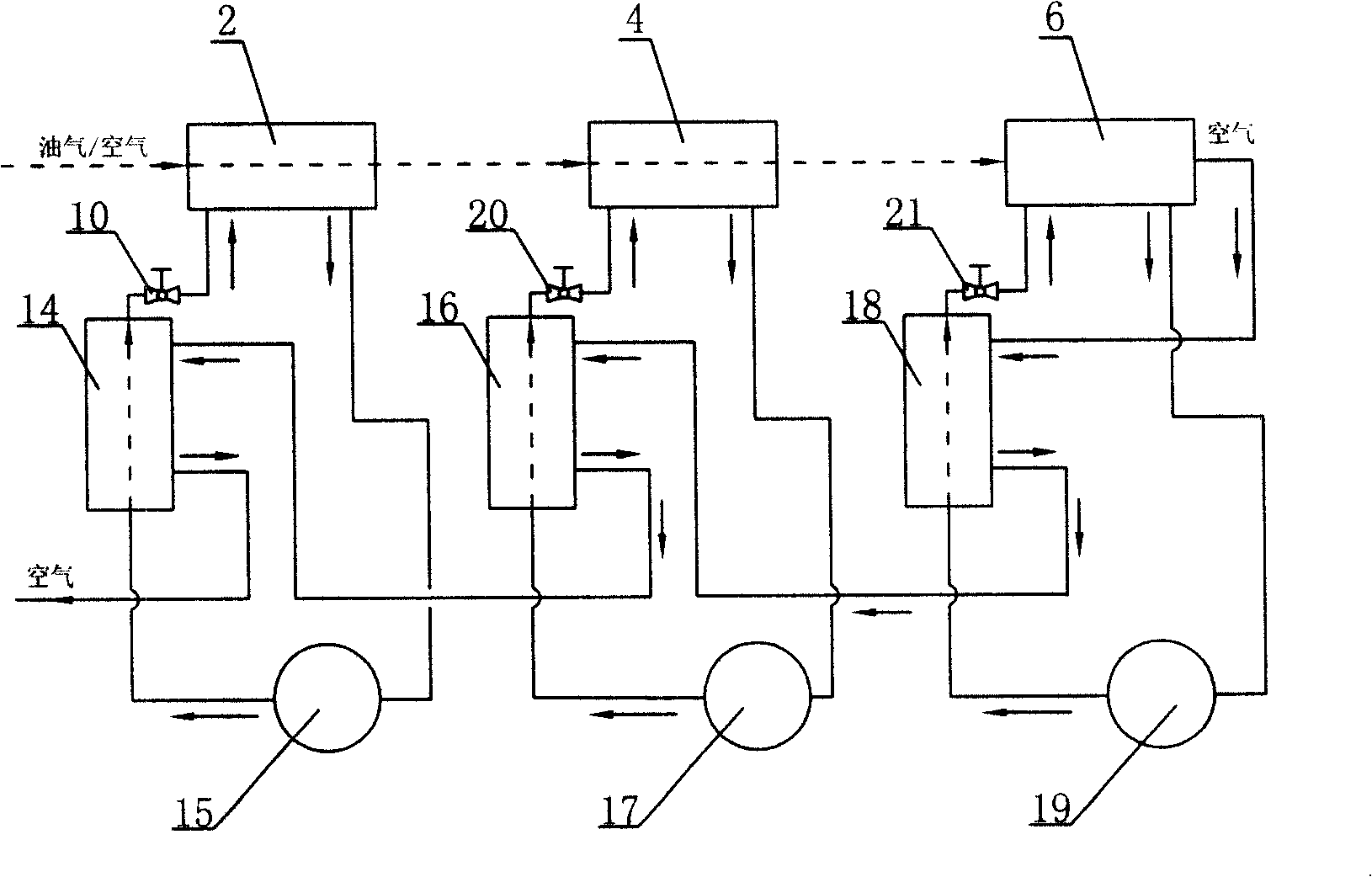

[0019] Such as figure 1 As shown, it is an embodiment of recovering the cooling capacity of directly condensing oil and gas from air tail gas. The system mainly includes the primary refrigeration system 7 (including the primary evaporator 2), the secondary refrigeration system 8 (including the secondary evaporator 4), the tertiary refrigeration system 9 (including the tertiary evaporator 6), and the primary oil-gas cooler 1. Secondary oil-air cooler 3. Third-stage oil-air cooler 5. The three evaporators of the refrigeration system are divided into three stages (first-stage evaporator 2, second-stage evaporator 4, and third-stage evaporator 6) to reduce the temperature of the fuel vapor / air mixture step by step, and the fuel vapor in the mixture is It is gradually condensed and separated, and finally only the air tail gas with a very low temperature leaves the evaporator 6 of the three-stage refrigeration system. This part of the air exhaust gas is led back to the front, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com