Vacuum refining system and method for molten steel

A technology of vacuum refining and vacuum pumping system, which is applied in the field of molten steel vacuum refining system in the metallurgical field, can solve the problems of high energy consumption, environmental pollution, poor impurity removal effect, etc., and achieves low energy consumption, simple equipment and small occupied space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

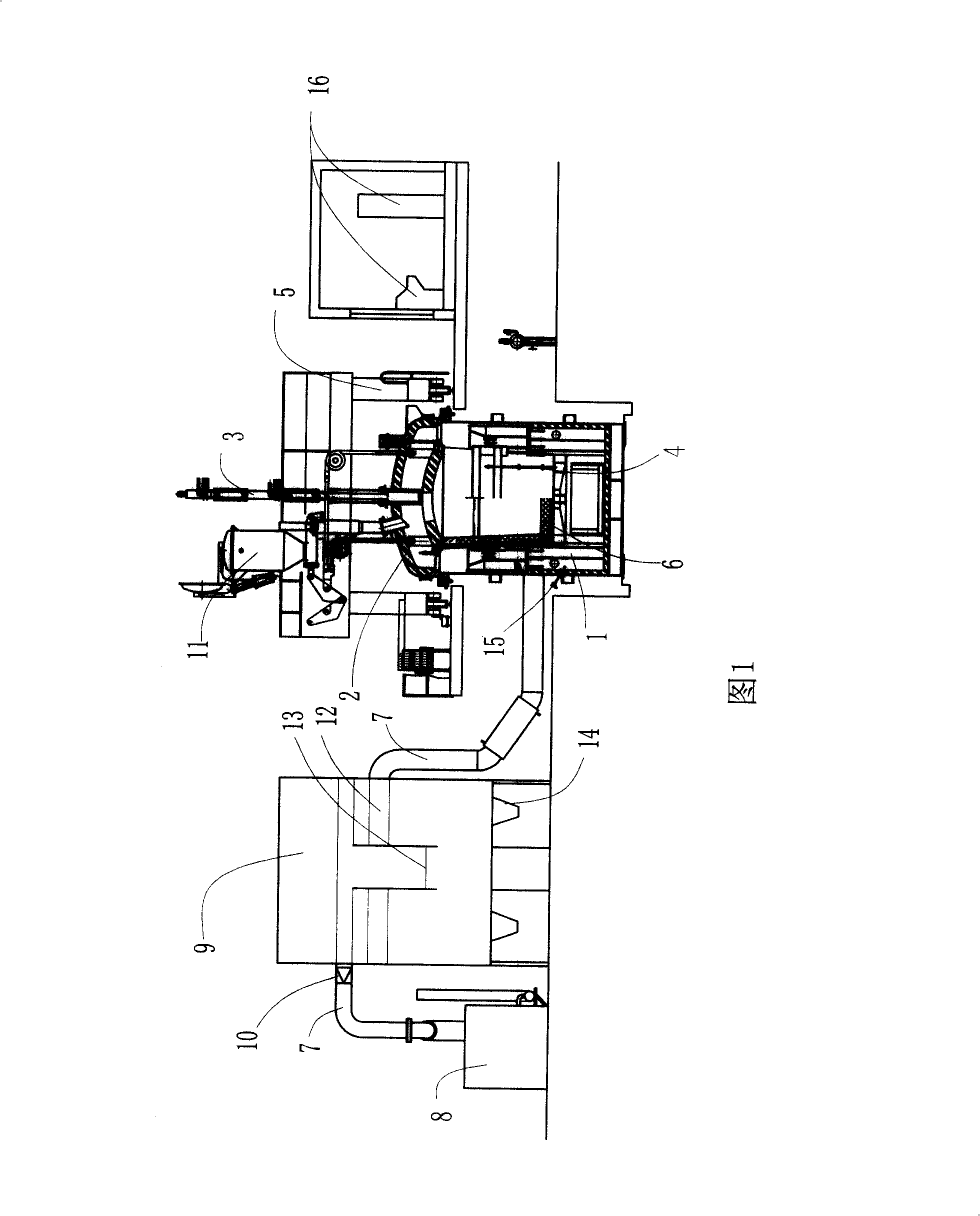

[0049]Referring to accompanying drawing 1, a kind of molten steel vacuum refining system comprises a vacuum tank, a vacuum system and an outlet pipeline 7 arranged between the vacuum tank and the vacuum system, the vacuum tank includes a vacuum tank body 1, a vacuum tank body 1 The vacuum tank cover 2 on the top, the ladle 6 arranged in the vacuum tank body 1, the oxygen system 3 arranged on the top of the vacuum tank and the argon system 4 at the bottom of the vacuum tank, the vacuum pumping system includes at least one vacuum mechanical pump group 8; The liquid vacuum refining system also includes an impurity removal and treatment system 9 arranged on the gas outlet pipeline 7; the impurity removal and treatment system 9 includes an annular cavity 12 and a filter cloth 13 arranged at the gas outlet of the annular cavity, and the annular cavity The bottom of 12 is also provided with an impurity collection channel 14; the molten steel vacuum refining system also includes a comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com