Modified TiC/Ti6Al4V composite material and manufacture method thereof

A composite material, ti6al4v technology, applied in the field of titanium-based composite materials, can solve problems such as difficulty in realization, and achieve the effect of avoiding complex procedures, improving shape, and simple operation technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

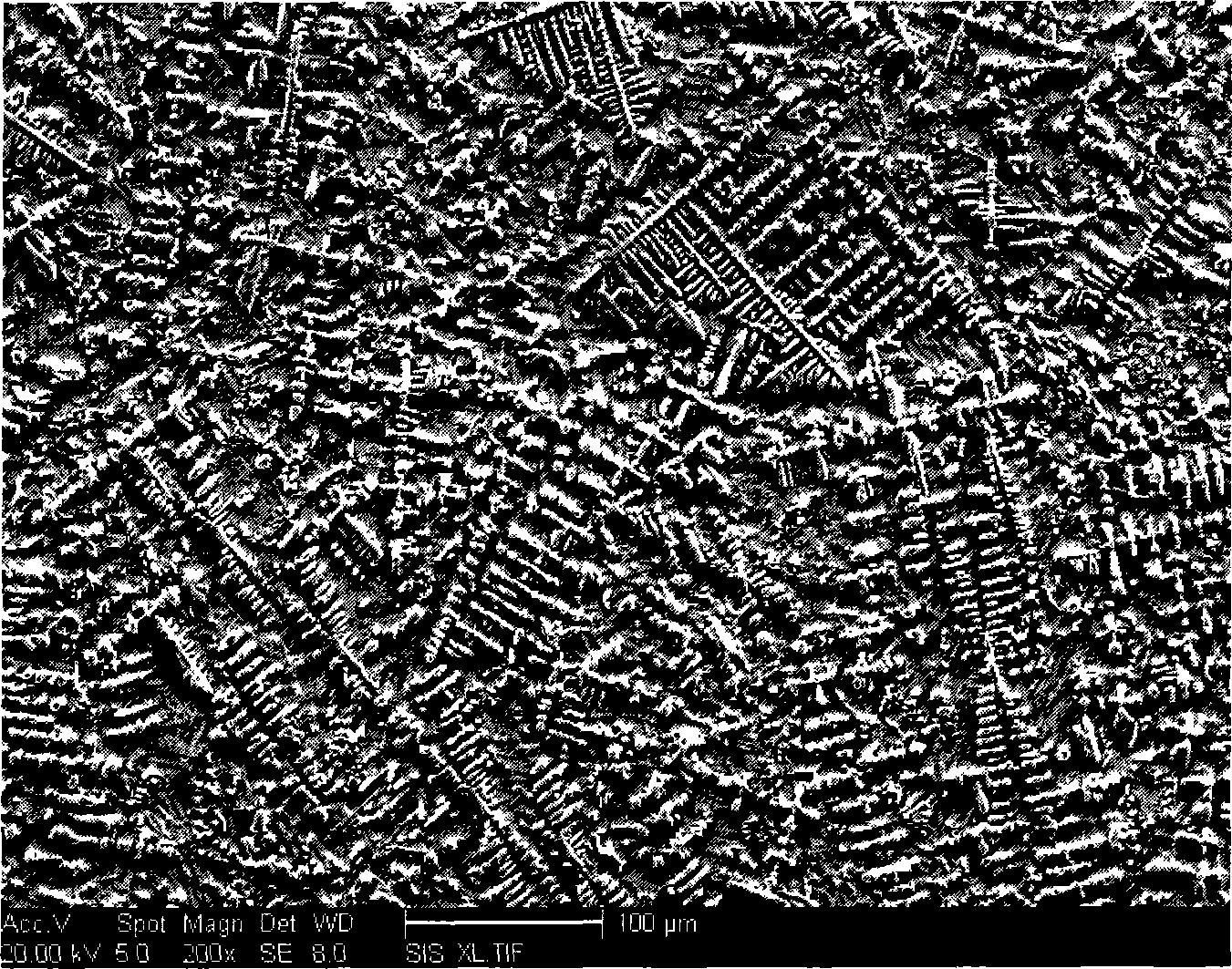

[0017] High-purity titanium powder (99.2%, 45μm), aluminum powder (99.6%, 29μm) and carbon black (99.8%, figure 1 shown. It can be seen that the TiC dendrites in the 15vol.%TiC / Ti6Al4V composite material are very coarse, with an average size of about 150 μm.

Embodiment 2

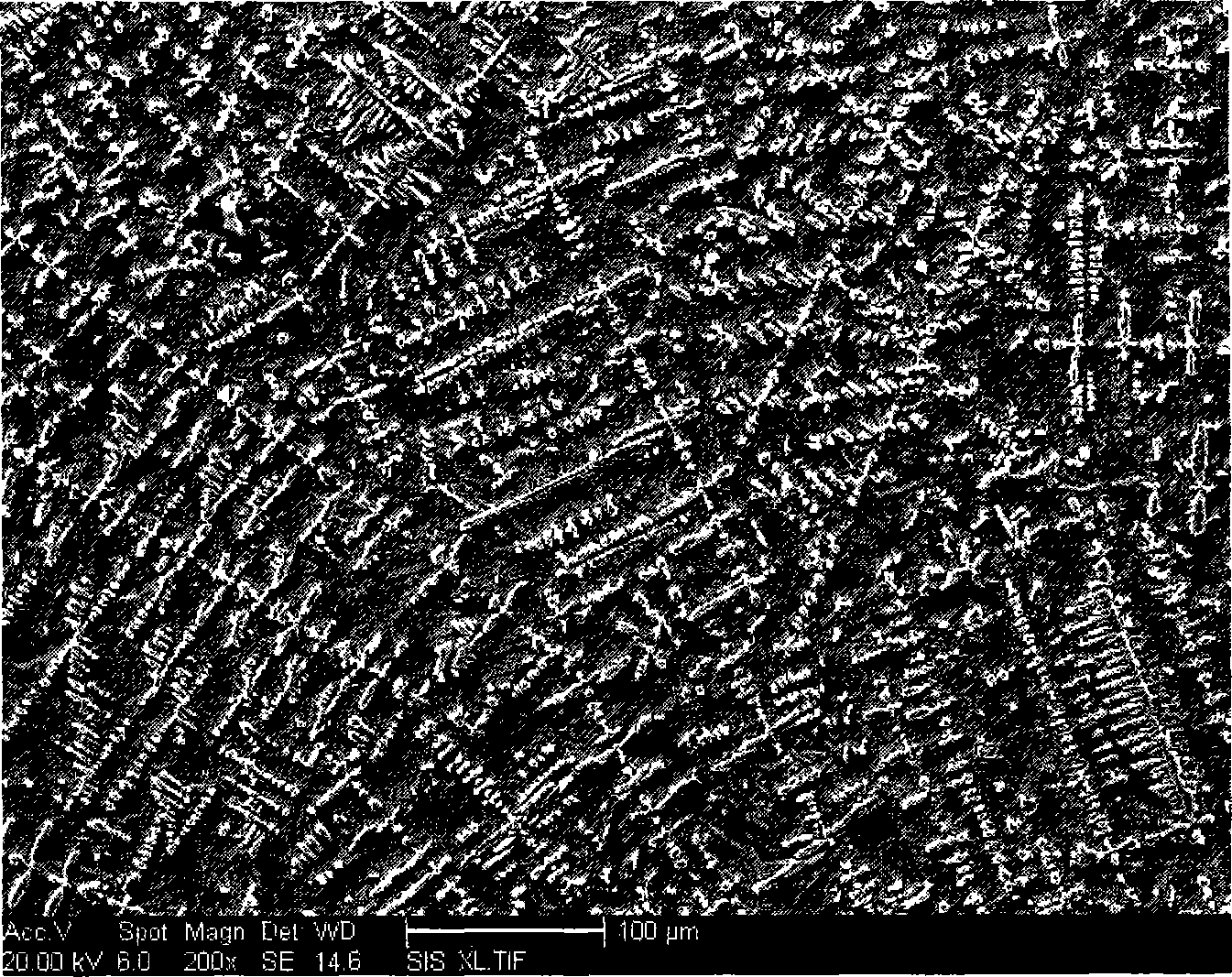

[0019] Firstly, Al / TiC prefabricated alloy is made according to the composition ratio. Then this alloy, titanium sponge, vanadium powder (99.9%, 20 μm), aluminum powder (99.6%, 29 μm) and boron powder (98%, 45 μm) are mixed according to the ratio of 15vol.% TiC / Ti6Al4V composite material, the addition of B The amount is 0.01%, melted in a vacuum water-cooled copper crucible non-consumable electric arc furnace, and stirred by an electromagnetic field, and the amount of each melting is 40g. Obtaining the metallographic structure observation of the as-cast composite material sample containing B obtained by the present invention, the results are as follows: figure 2 shown. It can be seen from the figure that the TiC morphology in the as-cast composite without adding B ( figure 1 ) compared with that, after being treated by the method proposed in the present invention, the TiC dendrites are obviously refined, and the distribution is more uniform, with an average size of about 10...

Embodiment 3

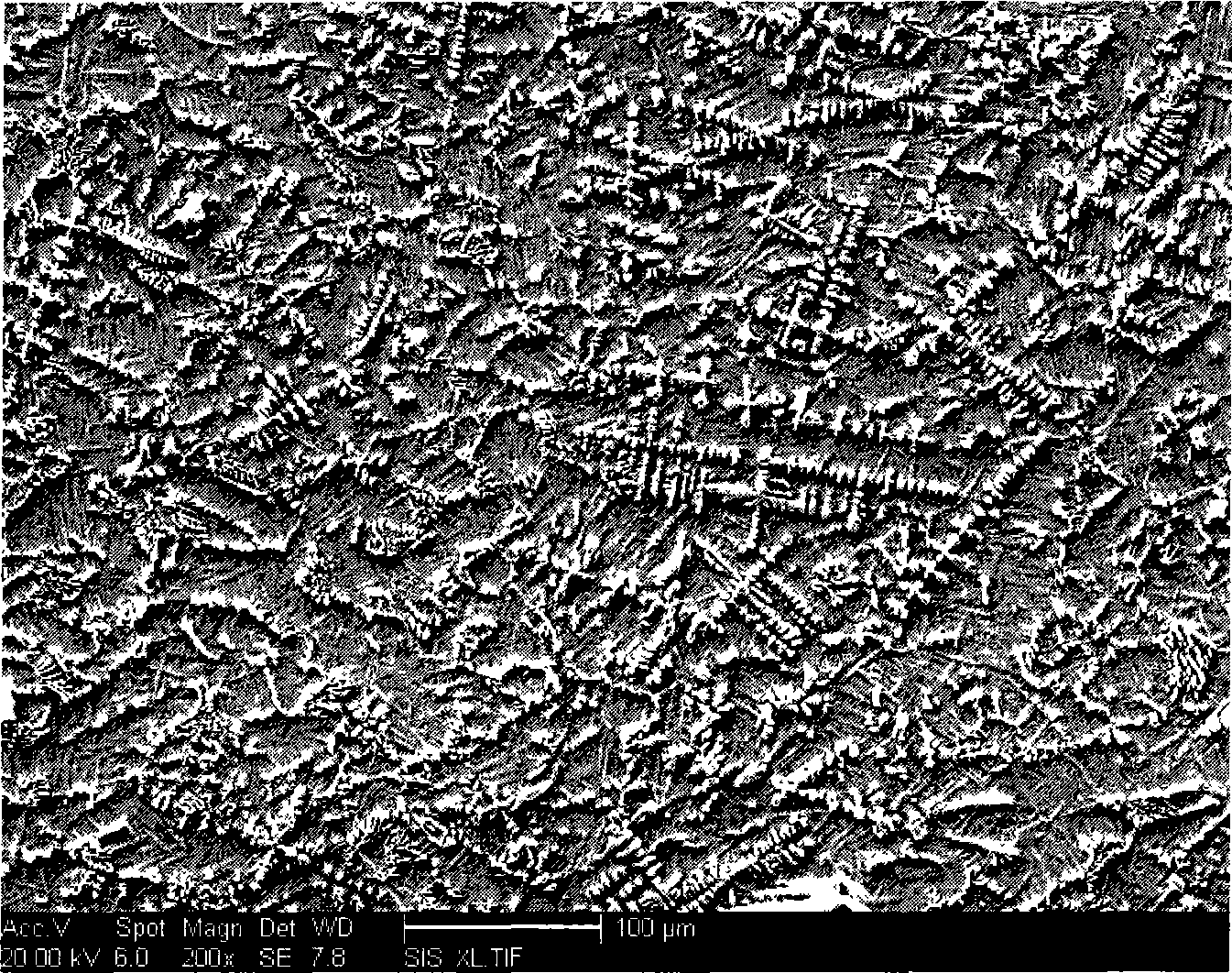

[0021] Firstly, Al / TiC prefabricated alloy is made according to the composition ratio. Then this alloy, titanium sponge, vanadium powder (99.9%, 20 μm), aluminum powder (99.6%, 29 μm) and boron powder (98%, 45 μm) are mixed according to the ratio of 15vol.% TiC / Ti6Al4V composite material, the addition of B The amount is 0.02%, and it is melted in a non-consumable electric arc furnace in a vacuum water-cooled copper crucible, and stirred by an electromagnetic field, and the amount of each melting is 40g. Obtaining the metallographic structure observation of the as-cast composite material sample containing B obtained by the present invention, the results are as follows: image 3 shown. It can be seen from the figure that after being treated by the method proposed in the present invention, the TiC dendrites are further refined, the average size is reduced to about 70 μm, and rod-like and chain-like TiC appear.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com