Method for preparing different crystal system calcium carbonate by using chitosan

A technology of chitosan and calcium carbonate, applied in the field of bionic materials, can solve problems that have not been studied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

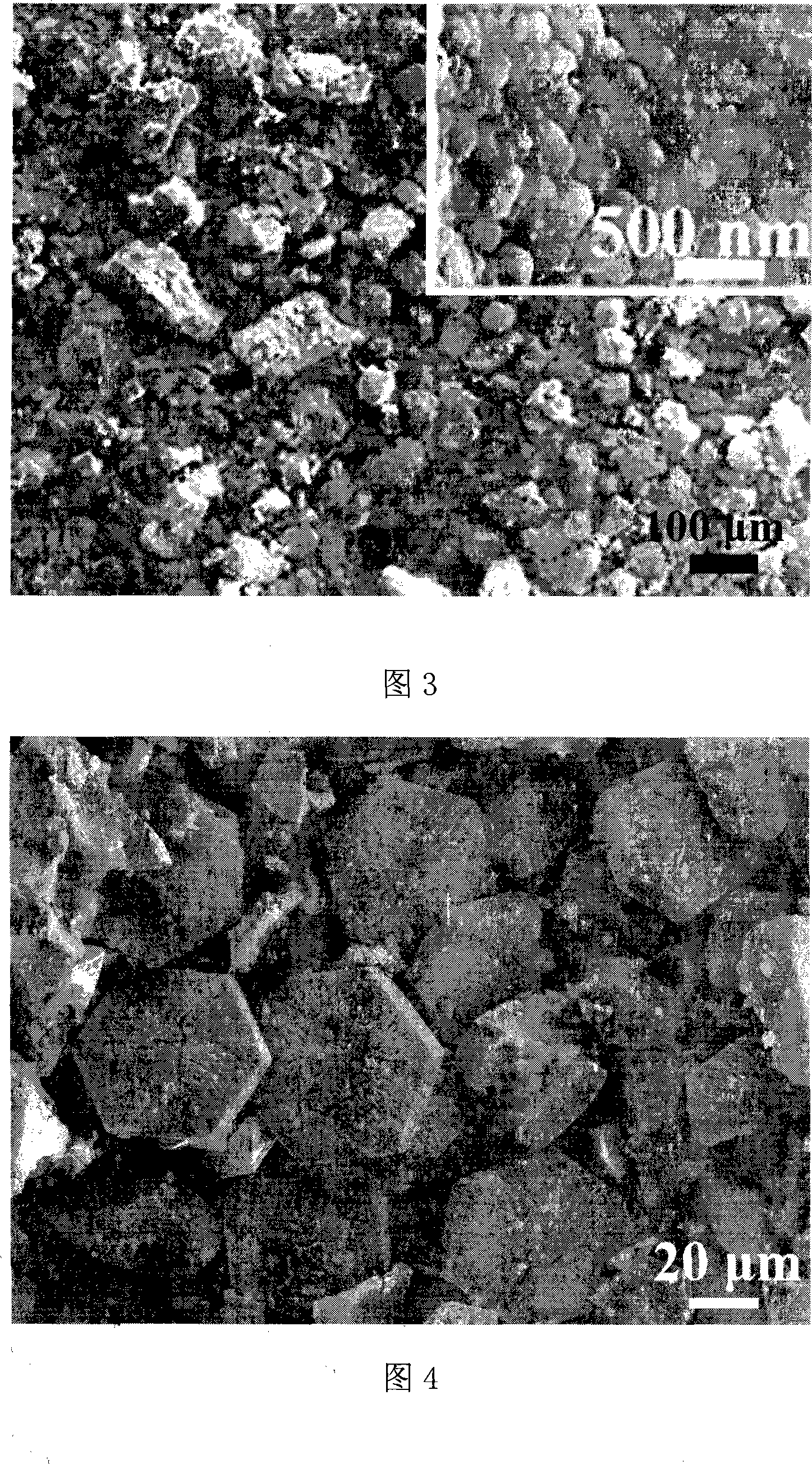

[0022] At first chitosan (degree of acetylation is less than 10%) is dissolved in the acetic acid aqueous solution that contains 1%, and concentration is 0.2g / ml, then adds calcium chloride dihydrate and urea to make the mol ratio of the two be 1: 5, And stir evenly, adjust the pH to be less than 6.0. The reactants were then transferred to a Teflon-lined autoclave and reacted at 100°C for 3 hours. After the reaction, the reactor was taken out and cooled to room temperature naturally. After filtration, the product was washed with distilled water and ethanol, respectively, and dried at room temperature.

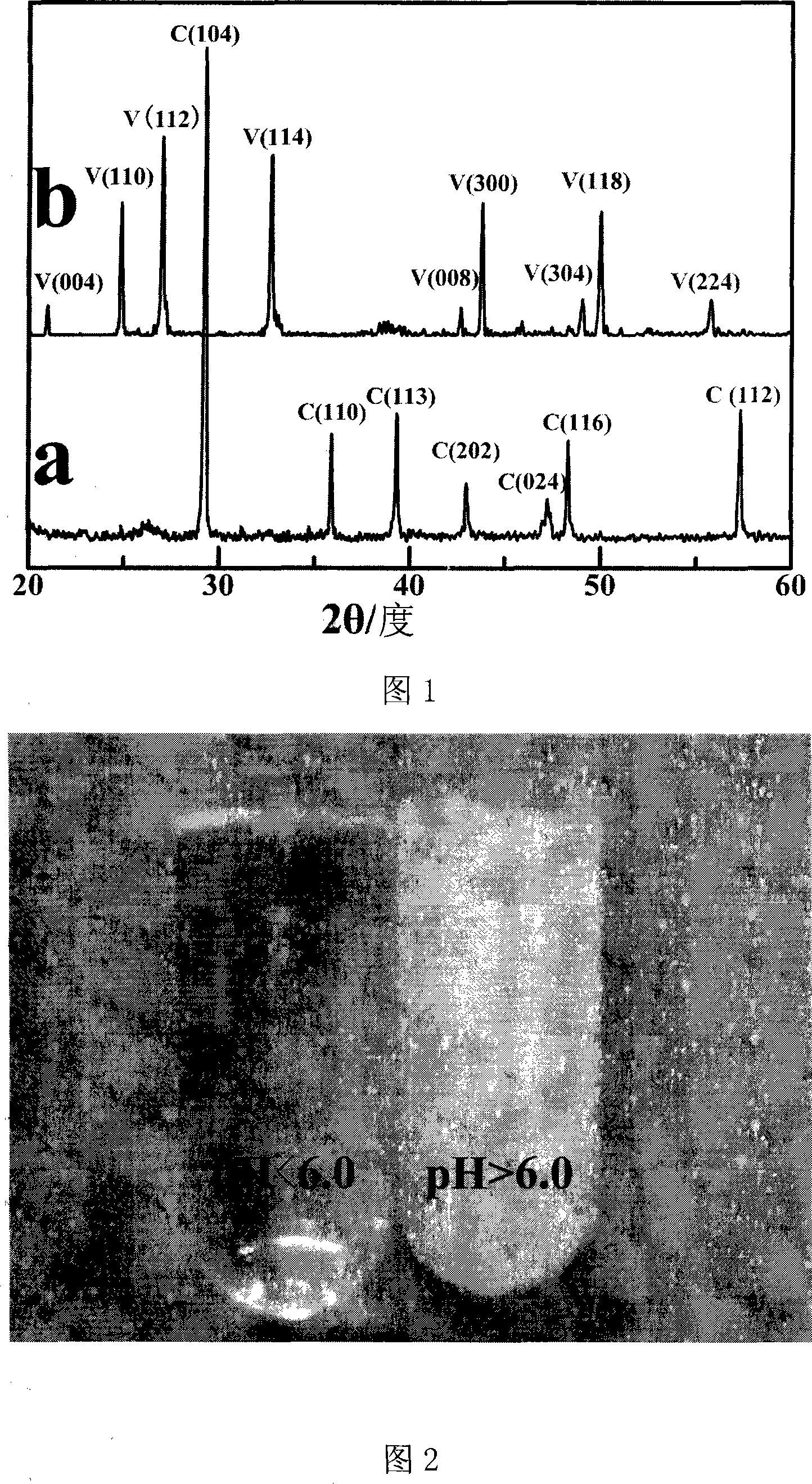

[0023] X-ray diffraction (XRD) analysis was carried out to the prepared product, and the obtained product was calcite-type calcium carbonate.

Embodiment 2

[0025] At first chitosan (degree of acetylation is less than 10%) is dissolved in the acetic acid aqueous solution that contains 1%, and concentration is 0.4g / ml, then adds calcium chloride dihydrate and urea to make the mol ratio of the two be 1: 5, And stir evenly, adjust the pH to be less than 6.0. The reactants were then transferred to a Teflon-lined autoclave and reacted at 100°C for 3 hours. After the reaction, the reactor was taken out and cooled to room temperature naturally. After filtration, the product was washed with distilled water and ethanol, respectively, and dried at room temperature.

[0026] X-ray diffraction (XRD) analysis was carried out to the prepared product, and the obtained product was calcite-type calcium carbonate.

Embodiment 3

[0028] At first chitosan (degree of acetylation is less than 10%) is dissolved in the acetic acid aqueous solution that contains 1%, and concentration is 0.6g / ml, then adds calcium chloride dihydrate and urea to make the mol ratio of the two be 1: 5, And stir evenly, adjust the pH to be less than 6.0. The reactants were then transferred to a Teflon-lined autoclave and reacted at 100°C for 3 hours. After the reaction, the reactor was taken out and cooled to room temperature naturally. After filtration, the product was washed with distilled water and ethanol, respectively, and dried at room temperature.

[0029] X-ray diffraction (XRD) analysis was carried out to the prepared product, and the obtained product was calcite-type calcium carbonate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com