Convenient method for directionally cutting any crystal face of crystal

A technology for cutting crystals and crystal planes, applied in stone processing tools, manufacturing tools, stone processing equipment, etc., can solve the problems of wasting crystals and cumbersome work, and achieve the effects of saving crystals, wide application and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1: Requirements in Hg 3 In 2 Te 6 A wafer with a (111) crystal plane cut out of the crystal, where Hg 3 In 2 Te 6 The theoretical value of 2θ corresponding to the (111) plane is 24.46°.

[0023] The steps for directional cutting are as follows:

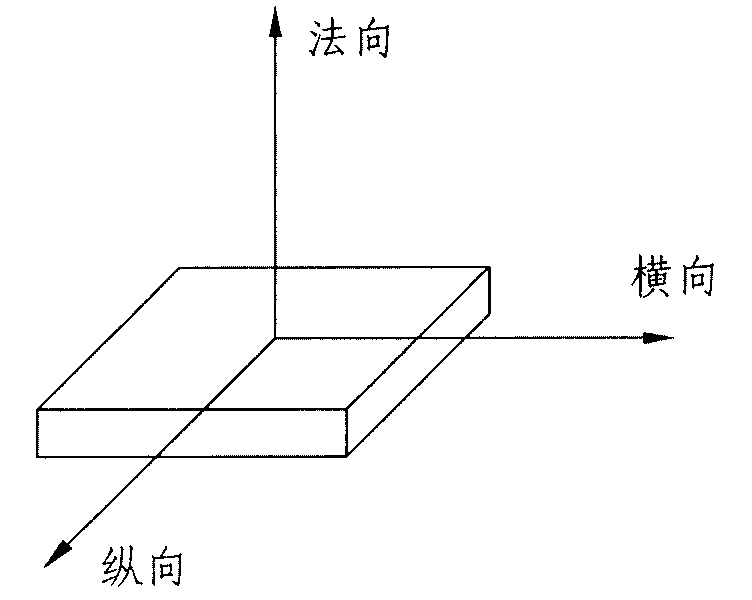

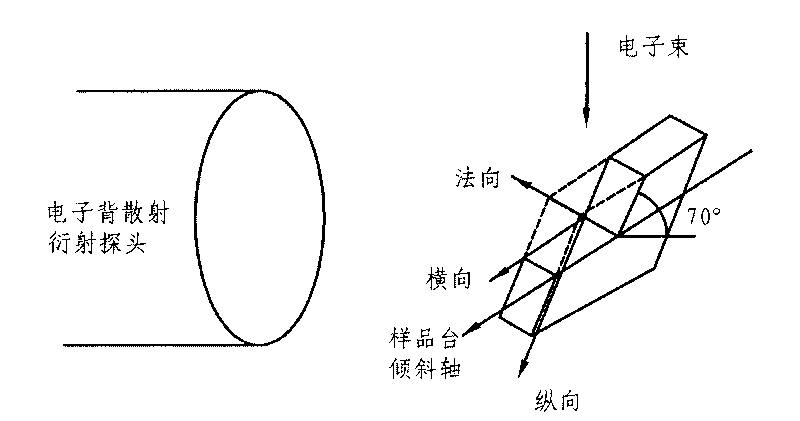

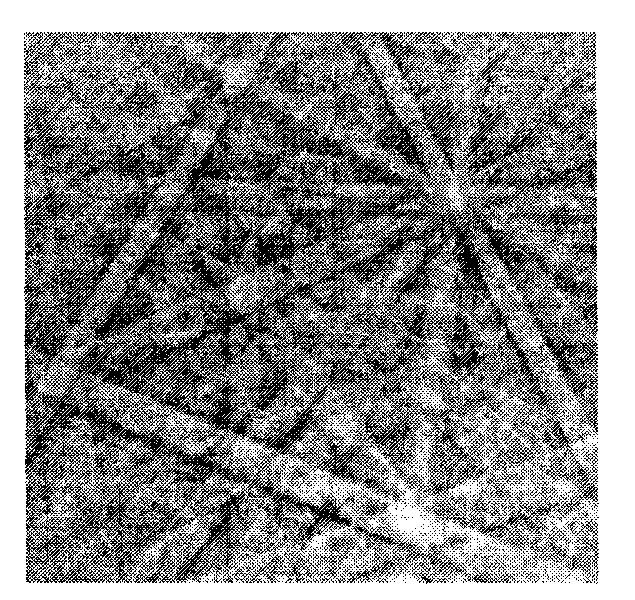

[0024] (a) Cut out any plane as a reference plane.

[0025] First stick the crystal on the cutting machine table with an adhesive, and then cut a wafer with uniform thickness from the edge of the crystal perpendicular to the table. The crystal plane close to the crystal on the wafer is used as a reference plane, and the reference plane is perpendicular to The downward direction of the pallet is regarded as the vertical direction, and the direction parallel to the right of the pallet is regarded as the horizontal direction. The vertical, horizontal and normal directions of the reference surface conform to the right-hand rule of the coordinate system, and then the reference surface is ground and polished until the s...

Embodiment 2

[0037] Embodiment 2: It is required to cut a wafer with (158) crystal plane on the germanium crystal, and the (158) crystal plane is the extinction surface of the germanium crystal.

[0038] The steps for directional cutting are as follows:

[0039] (1) Cut out any plane as a reference plane.

[0040] First stick the crystal on the cutting machine support with adhesive, and then cut out a wafer with uniform thickness from the edge of the crystal perpendicular to the support. The crystal plane close to the crystal on the wafer is used as the reference plane, and the reference plane is perpendicular to the support. The downward direction of the platform is regarded as the longitudinal direction, and the direction parallel to the right of the support platform is regarded as the transverse direction. The longitudinal, transverse and normal directions of the reference surface conform to the right-hand rule of the coordinate system, and then the reference surface is ground and polis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com