High-temperature-phase tellurium barium molybdate crystal as well as preparation method and applications thereof

A technology of barium tellurium molybdate and crystal, which is applied in the field of high-temperature phase barium tellurium molybdate crystal, preparation, new nonlinear optical crystal and its preparation, and achieves the effect of simple operation, low price and testing physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

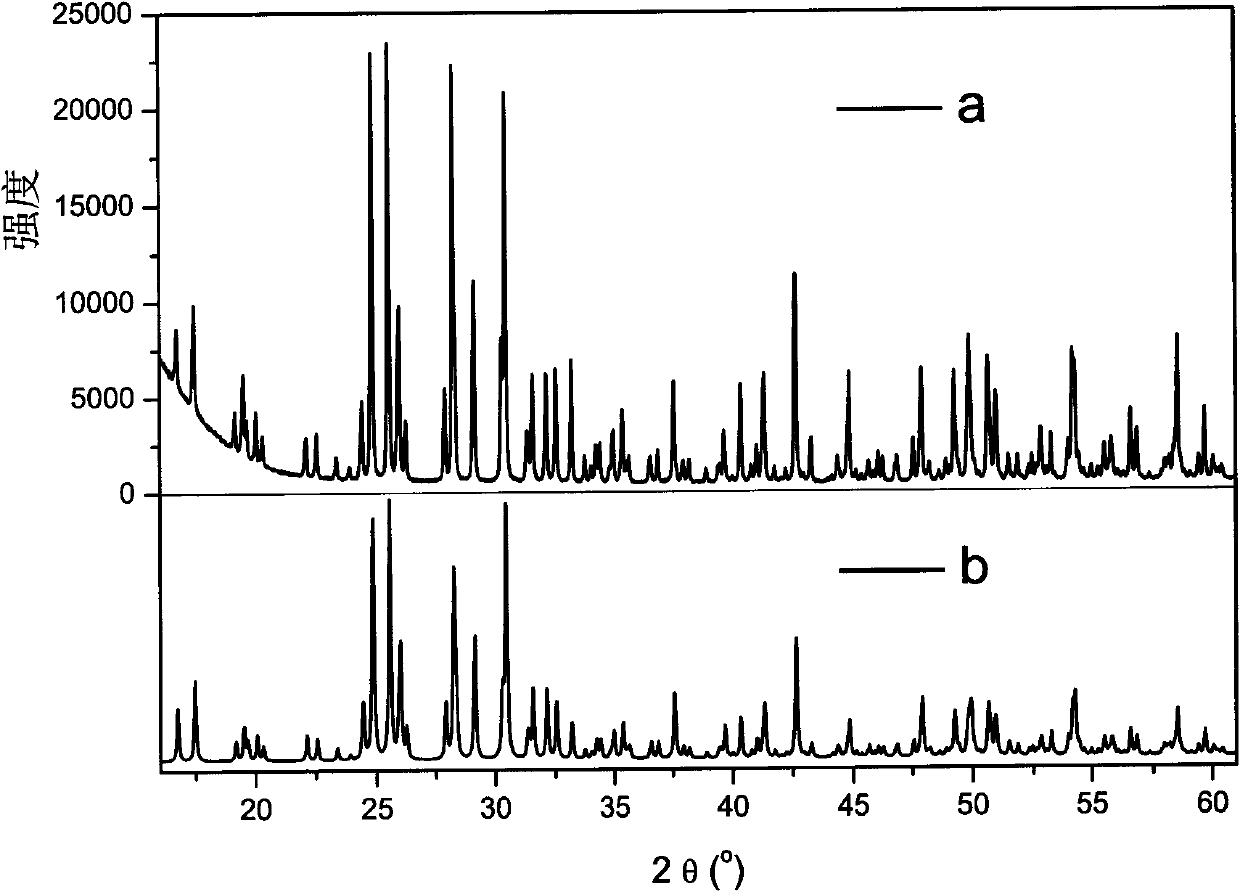

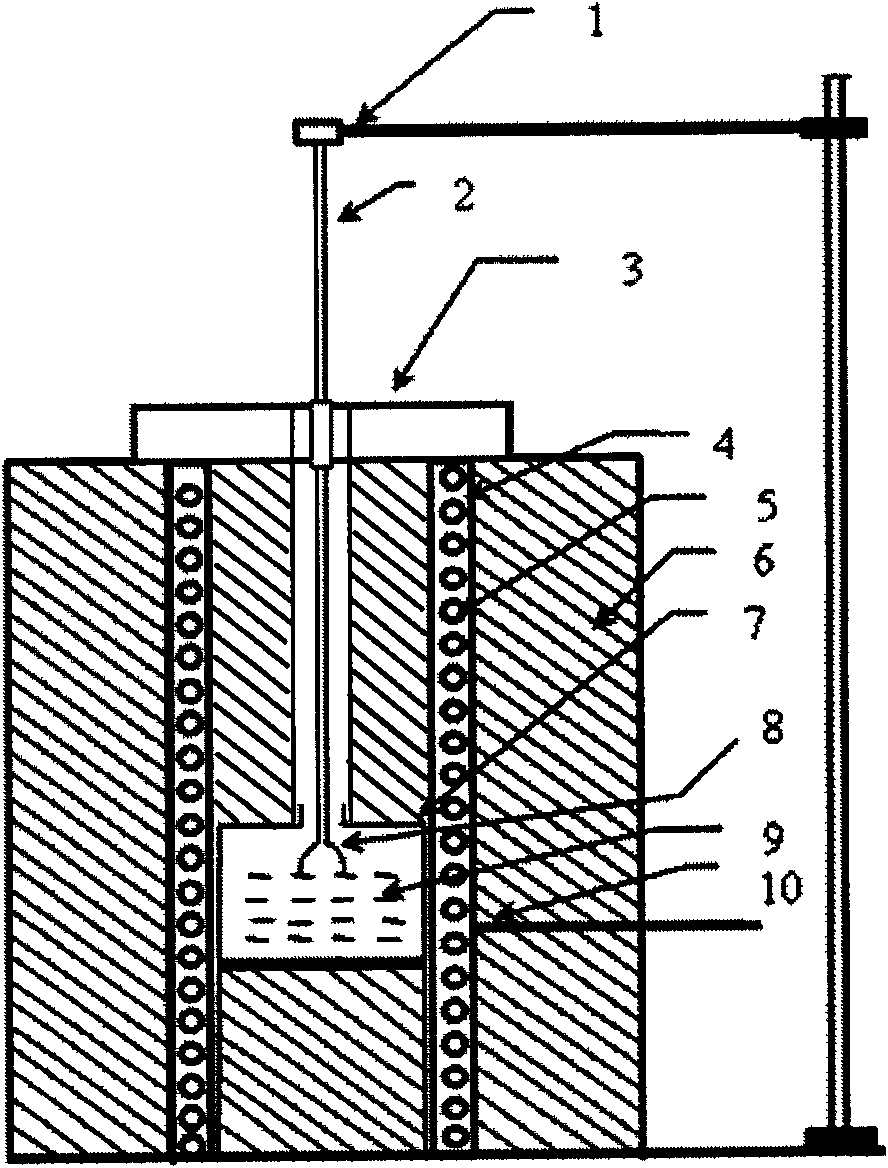

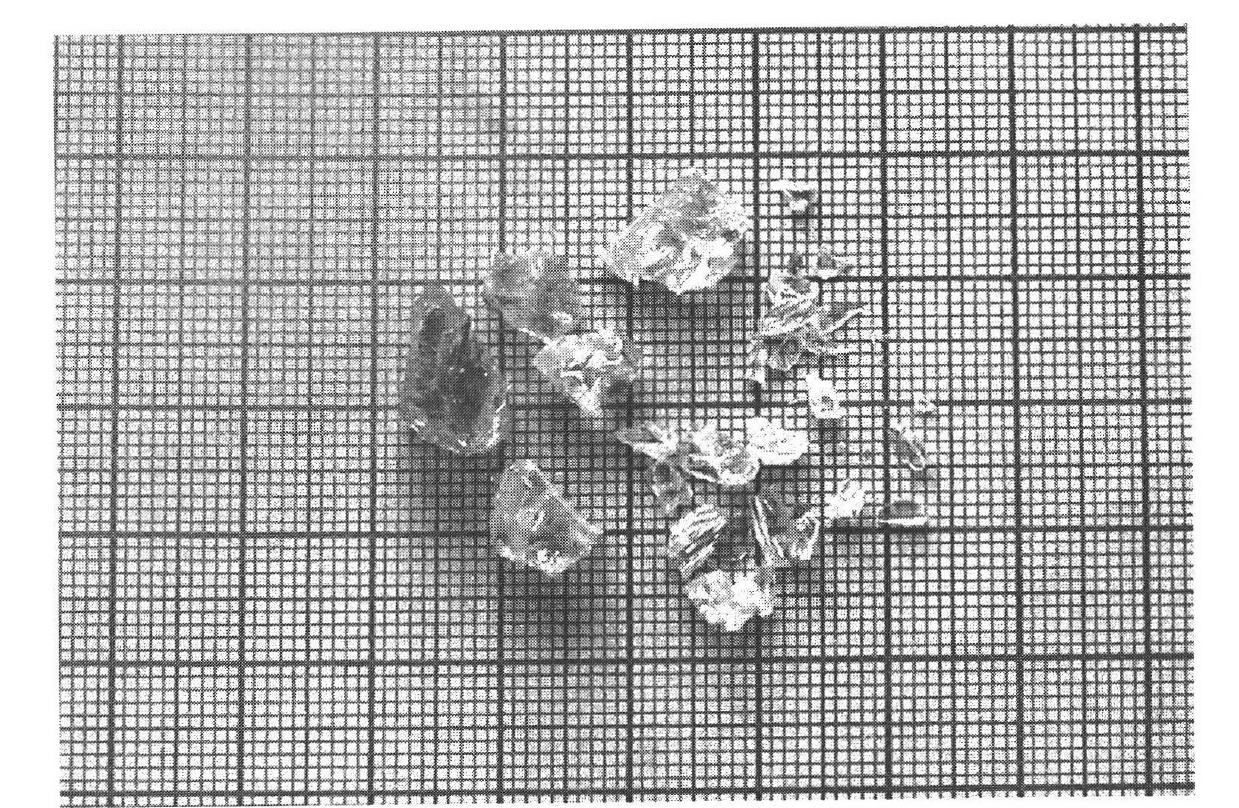

[0040] Raw material BaCO 3 , TeO 2 and MoO 3 According to the stoichiometric ratio, synthesize the high-temperature phase barium tellurium molybdate polycrystal, and add it to the flux system TeO 2 -MoO 3 (TeO 2 : MoO 3 = 1.2:1), the molar ratio of the high-temperature phase barium tellurium molybdate polycrystal to the flux is 1:2, mix evenly, put it into a platinum crucible with a volume of Φ60mm×60mm, heat up to 650°C to melt and mix the raw materials Uniform; then put in the seed rod, and cool down to 560°C at a rate of 1.2-1.5°C / h, the growth cycle is 12 days, and a small colorless single crystal is obtained, such as image 3 shown. Structural analysis was carried out on the obtained crystal, and its space group was obtained as Pca2 1 , a=14.8683(2) b=5.66360(10) c=17.6849(3) α=β=γ=90°, and its powder X-ray diffraction pattern (such as figure 1 Shown) is consistent with the theoretical calculation, indicating that the obtained high-temperature barium telluri...

Embodiment 2

[0042] Embodiment 2: raw material BaCO 3 , TeO 2 and MoO 3 According to the stoichiometric ratio, synthesize the high-temperature phase barium tellurium molybdate polycrystal, and add it to the flux system TeO 2 -MoO 3 (TeO 2 : MoO 3 = 1.2: 1), the molar ratio of high-temperature phase barium tellurium molybdate polycrystal and flux is 1: 2, put into the platinum crucible that volume is Φ80mm * 80mm, be heated up to 650 ℃ and make raw material melting and mix homogeneously; Then Cool down to the saturation point of the solution. At this time, put the preheated seed crystal into the solution. The seed crystal is taken from the high-temperature phase barium tellurium molybdate crystal that crystallized spontaneously in Example 1; 1~10s, running for 30~180s, intermittent 5~50s, and cooling down to 540℃ at a rate of 0.01-0.1℃ / h, the growth cycle is 45 days, and a colorless and transparent block single crystal can be obtained, such as Figure 4 shown. The powder X-ray diffra...

Embodiment 3

[0046] Embodiment 3: raw material BaCO 3 , TeO 2 and MoO 3 Weigh at a molar ratio of 1:3.4:4, mix evenly, put it into a platinum crucible with a volume of Φ80mm×80mm, raise the temperature to 650°C to melt the raw materials and mix them evenly; α-BaTeMo 2 o 9 The seed crystal is lowered into the solution, and the crystal rotation parameters are set as follows: speed 5-50rpm, acceleration 1-10s, operation 30-180s, intermittent 5-50s, and cooling at a rate of 0.01-0.1°C / h to 535°C. The growth period is 50 days, and a colorless and transparent bulk single crystal is obtained, such as Figure 5 shown. The powder X-ray diffraction pattern is consistent with the theoretical calculation, indicating that the obtained high-temperature barium tellurium molybdate crystal is orthorhombic.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com