General-purpose plug socket tools

A jig and plug hole technology, applied in the direction of electrical components, printed circuit manufacturing, printed circuit, etc., can solve the problems that affect the timeliness of plug hole production, insufficient strength of the base material on the jig, and production interruption, so as to ensure the production of products High quality, not easy to contaminate fixtures, easy to maintain and clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the embodiments in the accompanying drawings:

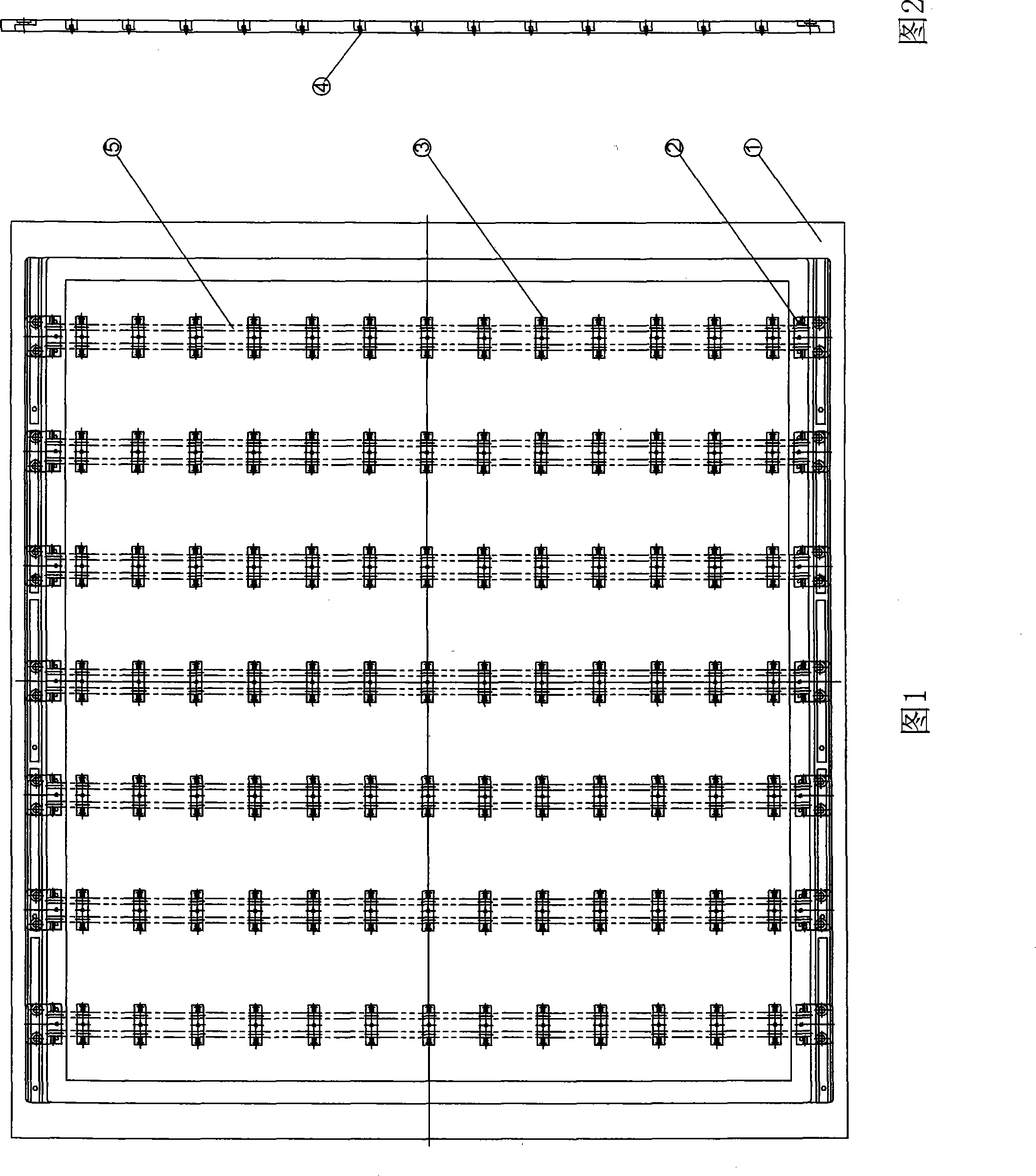

[0020] The present invention is mainly composed of a base plate 1 , a sliding block 2 , a PIN nail fixing block 3 , a PIN needle 4 , and a sliding rail 5 .

[0021] The present invention mainly adopts the sliding block 2 to be mounted on the bottom plate 1, and the sliding rail 5 to be mounted on the sliding block 2. All the components on the sliding rail 5 will move in the X direction together with the sliding rail 5 along with the sliding block 2. Block 2 is provided with holes. The PIN nail fixing block 3 is mounted on the sliding rail 5 and can move in the Y direction along the sliding rail 5, and the PIN nail fixing block 3 is provided with a hole. The PIN needle 4 is fixed on the PIN nail fixing block 3. The position of the PIN needle 4 is determined by the slider 2 and the PIN nail fixing block 3 to determine its coordinates. The PIN needle 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com