Electrochemical cell stack

A battery stack and electrochemical technology, applied in electrochemical generators, fuel cells, solid electrolyte fuel cells, etc., can solve problems such as inapplicable spring systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

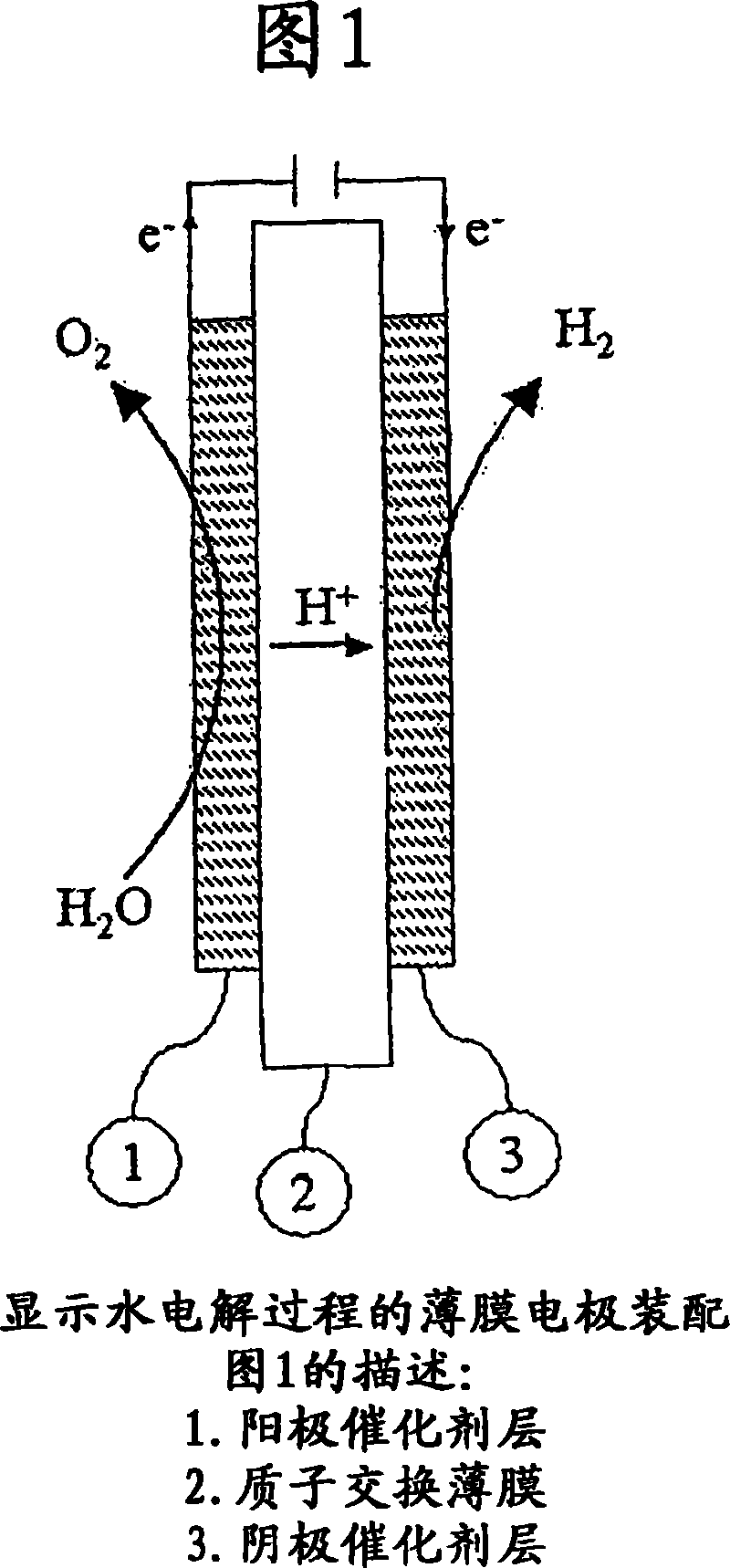

[0049] Figure 1 illustrates the water electrolysis process in a PEM cell, where water is supplied to the anode side 1 and, under an applied electric potential field, becomes split into oxygen, protons and electrons. The proton migrates to the cathode side 3 where it recombines with an electron to form hydrogen gas.

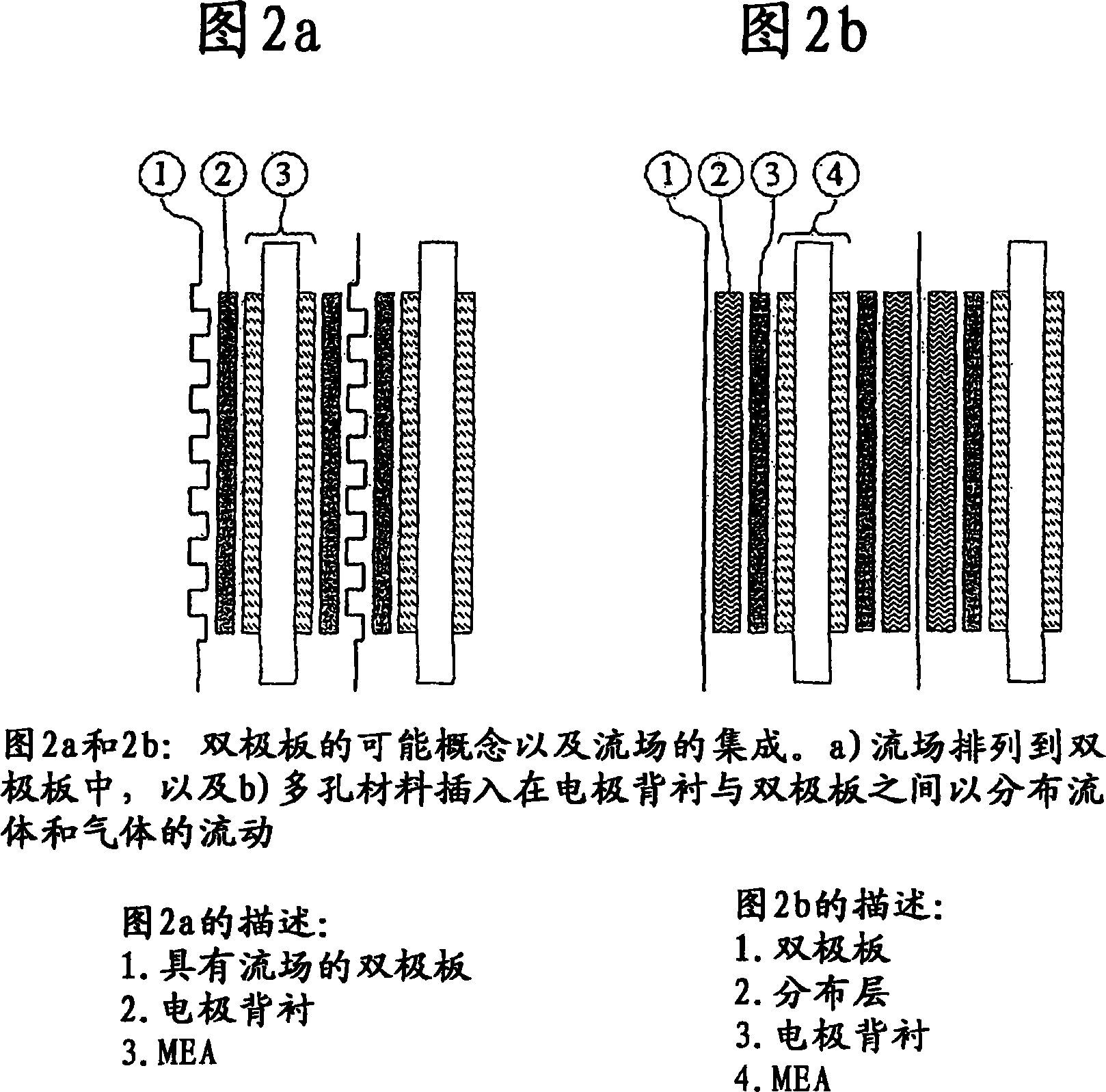

[0050] Figures 2a and 2b show two typical concepts where a) the flow pattern is integrated into the bipolar plate or b) the porous layer is inserted between the bipolar plate and the electrode backing. This porous layer must then provide electrical contact between the bipolar plate and the electrode backing, and it must provide fluid flow into and out of the battery compartment. A gasket is placed around the electrode backing area between the membrane and the bipolar plate (not shown in Figure 2). Fluid flow to and from the cell is typically through gaskets and channel arrangements within the bipolar plates.

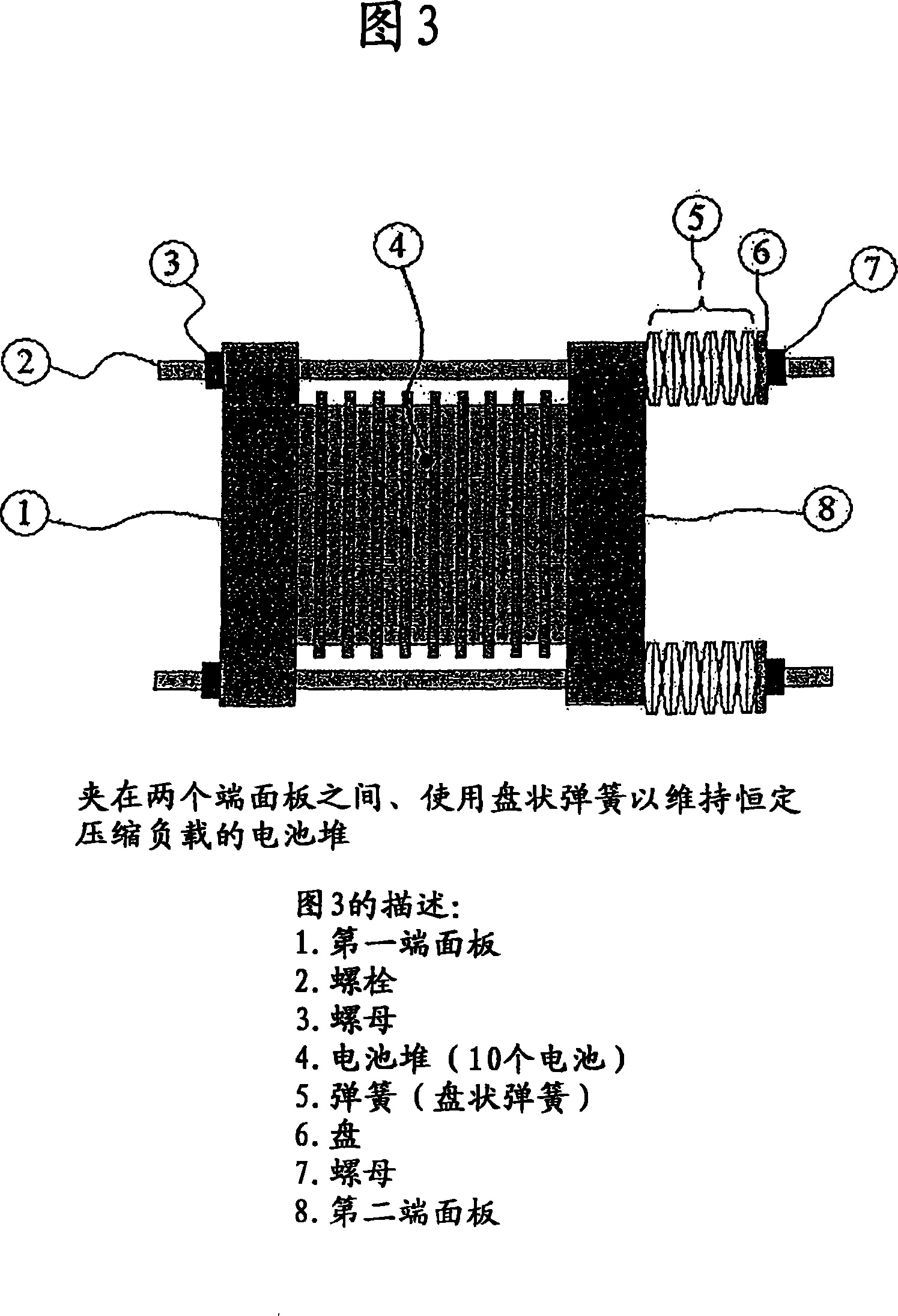

[0051] FIG. 3 shows a battery stack 4 of 10 cells co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com