Sterile liquid nitrogen filling apparatus

A manufacturing method and technology of a manufacturing device, which are applied to the manufacturing field of container and packaged beverages, can solve the problems of a large amount of energy and time, a narrow range of component material selection, and the inability to fully guarantee sterility, etc., and achieve the effect of preventing the deterioration of the inner solution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

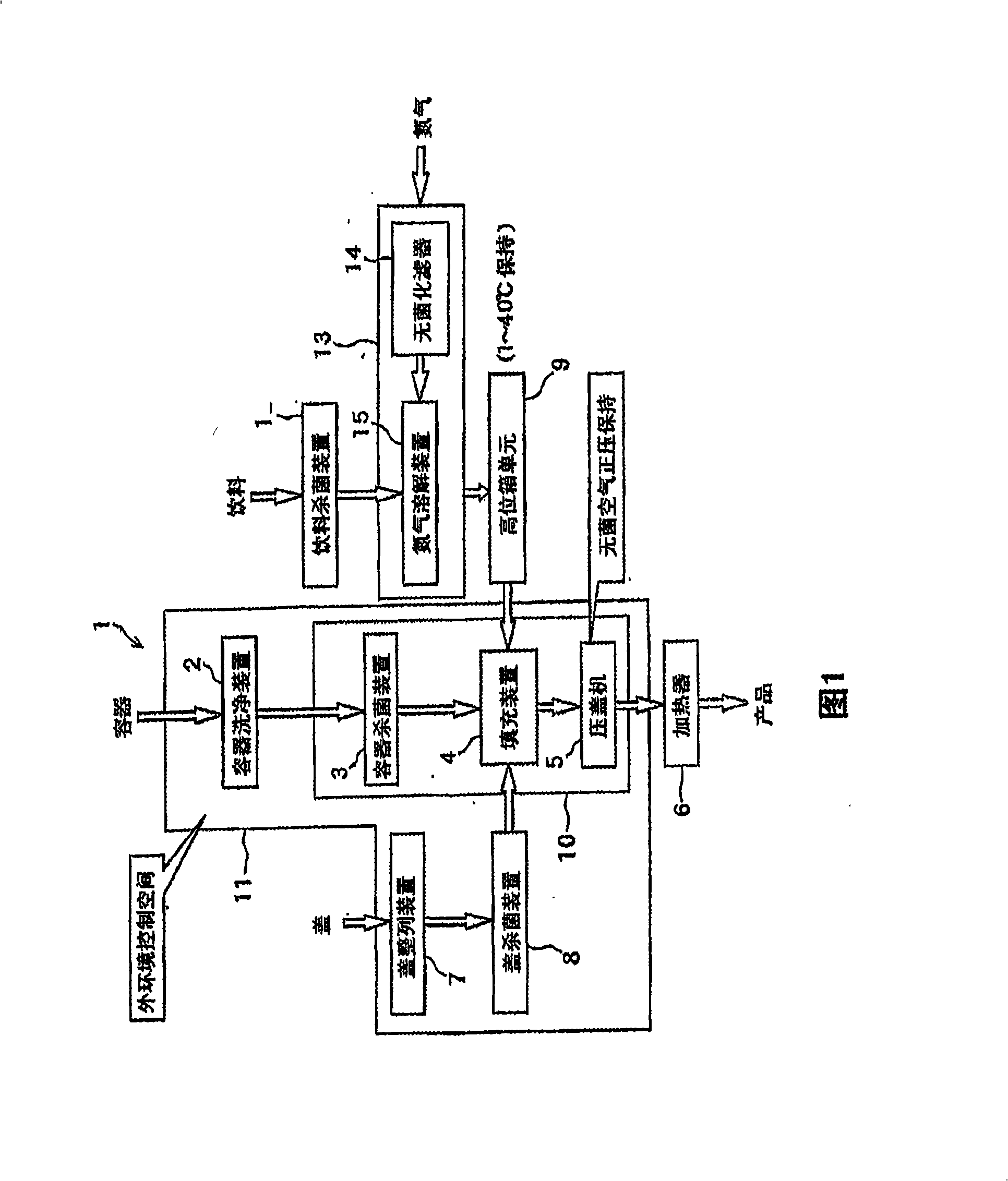

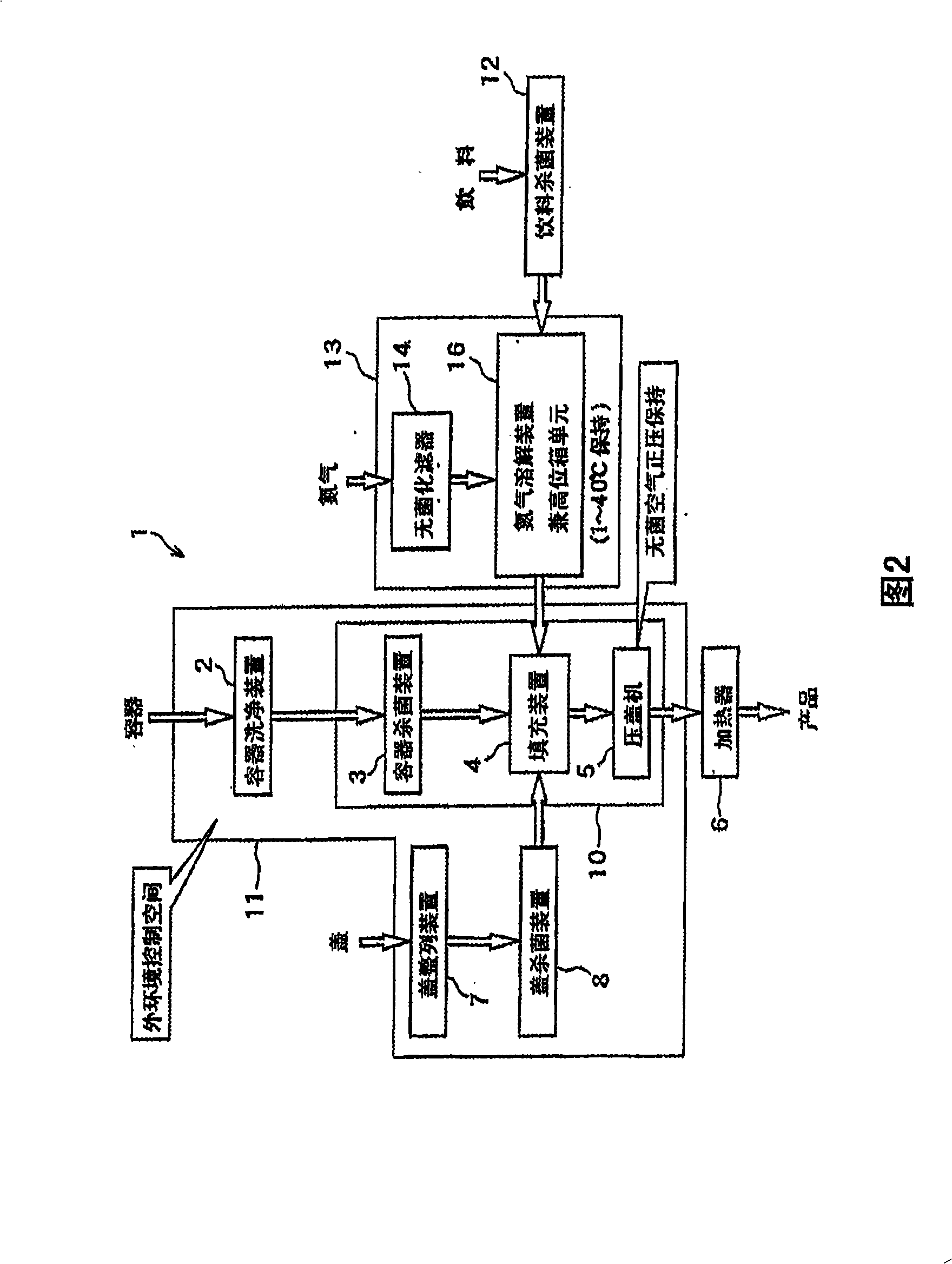

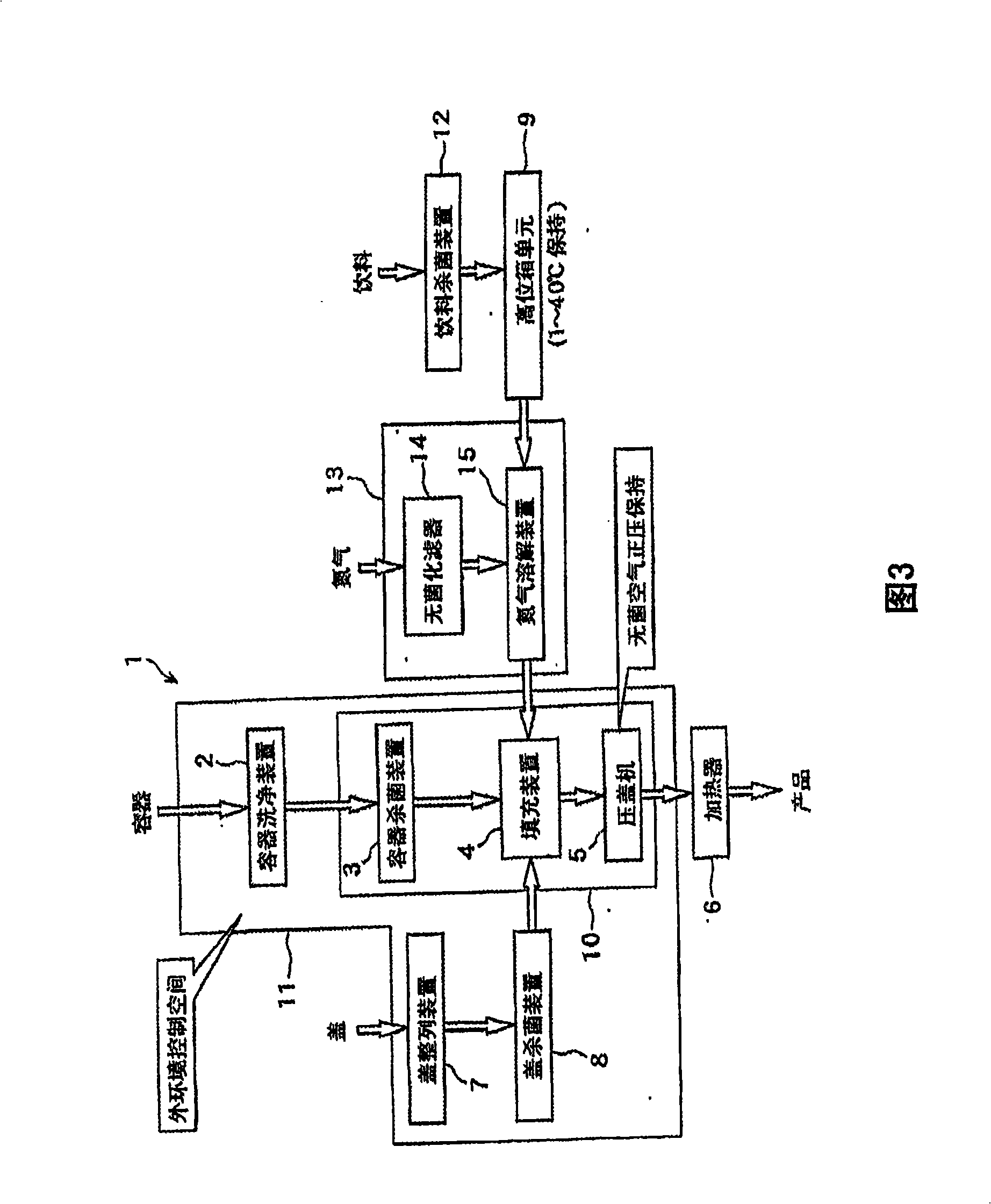

Method used

Image

Examples

Embodiment 1

[0164] Using a device for absorbing nitrogen, in a tank filled with nitrogen that has been filtered and sterilized by a filter (material: PTFE 0.2 micron filter, after steam sterilization), heat-sterilized water (sterilized in UHT In the device, preheat at 80°C, sterilize at 135°C, hold for 30 seconds, and cool at 25°C) for absorption treatment. The treatment conditions were a tank capacity of 71 L, a water temperature of 25° C., a pressure of 0.5 MPa and 0.3 MPa, and 2 L / min. In addition, the inside of the absorber, the liquid supply piping, and the air supply piping are heated and sterilized in advance. Fill 510ml of water after pressure absorption treatment (headspace volume 10ml) into pre-sterilized such as Image 6 In the shown 500ml carbon dioxide bottle (average wall thickness 0.2mm, fully filled internal capacity 520ml), after filling for 30 seconds, cap and seal, then measure the internal pressure, the results are as follows.

[0165] Table 1

[0166]

[0167] M...

Embodiment 2

[0169] Fill 510ml of heat-sterilized water in the PET bottle (in a UHT sterilizer, preheat 80°C, sterilize at 135°C, hold for 30 seconds, cool down at 20°C) to the pre-sterilized as Image 6 In the shown 500ml carbon dioxide bottle (average wall thickness 0.2mm, full filling capacity 520ml), then filter the liquid nitrogen that is sterilized by filter (material: PTFE 0.2 micron filter, after steam sterilization treatment, after drying) Fill only the amounts indicated in Table 2 and seal quickly with sterilized caps. The internal pressure of the bottle was measured, and the results are shown in Table 2.

[0170] Microbiological examination is carried out on the products produced using the above-mentioned manufacturing method and apparatus. After storing the product at 30°C for 2 weeks, pass the microbial inspection (full membrane filter (after filtering all the contents, store it at 30°C on standard agar medium for 1 week, membrane filter, material, cellulose mixed ester, por...

Embodiment 3

[0174] The heat-sterilized water in the PET bottle (in a UHT sterilization device, preheated to 80°C, sterilized at 135°C, kept for 30 seconds, cooled to 25°C, and then filtered and sterilized through a filter in a sterile tank Nitrogen bubbled and maintained at 301KPa) 510ml filled (headspace volume 10ml) into pre-sterilized such as Image 6 In the shown 500ml carbon dioxide bottle (average wall thickness 0.2mm, fully filled internal capacity 520ml), then fill it with liquid nitrogen treated by filter sterilization (material: PTFE 0.2 micron filter, after steam sterilization treatment, after drying) 20 mg, and then quickly sealed with a sterilized cap. The internal pressure of the bottle was measured, and the result was an average of 301KPa.

[0175] Microbiological examination is carried out on the products produced using the above-mentioned manufacturing method and apparatus. After storing the product at 30°C for 2 weeks, pass the microbial inspection (full membrane filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com