Resin-coated seamless aluminum can and resin-coated aluminum alloy lid

A technology of seamless aluminum cans and aluminum alloys, applied in coatings, metal material coating processes, anti-corrosion coatings, etc., can solve the problems of non-corrosion resistance and tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0148] · Polymer modulation

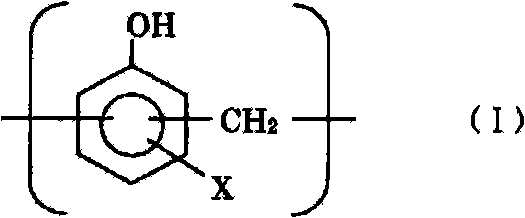

[0149] The water-soluble polymer is a polymer represented by formula (I), wherein X is an independent hydrogen atom or Z=-CH in each structural unit represented by formula (I) 2 N(CH 3 ) 2 , the introduction efficiency of Z groups is 0.5 per benzene ring, and the average molecular weight when all X are hydrogen atoms is 3000.

[0150] Calculation of the introduction efficiency of Z base

[0151] The C, H, N, and S elements contained in the prepared polymer were quantified using an EA1108 elemental analysis device manufactured by FISONS. According to the quantitative results, the efficiency of Z group introduction was calculated.

[0152] ·Preparation of treatment liquid

[0153] Pour ion-exchanged water at normal temperature into a container with a stirring device. Add 71 g / L of 40% zirconium fluoride hydrochloride (Zr content 17.6%), 15 g / L of 85% phosphoric acid, and 9 g / L of 55% hydrogen fluoride acid while stirring at room temperature, a...

Embodiment 2

[0155] The water-soluble polymer is a polymer represented by formula (I), wherein X is an independent hydrogen atom or Z=-CH in each structural unit represented by formula (I) 2 N(CH 3 ) 2 , the introduction efficiency of the Z group is 0.5 per benzene ring, and the average molecular weight when all X are hydrogen atoms is 1500, the same as in Example 1 except that.

Embodiment 3~16、 comparative example 1~8

[0157] In the above-mentioned Example 1, the zirconium component, the phosphorus component, the polymer concentration, the pH, the average molecular weight of the polymer, and the Z group introduction efficiency of the polymer were changed as shown in Table 2, and the others were the same as in Example 1.

[0158] (cleaning of aluminum alloy plate)

[0159] Using the strong base degreasing agent "Fine Cleaner 4377" (trademark, manufactured by Japan Parker Seisei Co., Ltd.) sold on the market, under the conditions of chemical concentration 20g / L, processing temperature 60 ℃, and processing time 7 seconds, the market Aluminum-manganese alloy plates sold on the Internet (for cans = JIS A3004 plate thickness: 0.3 mm plate size: 200 × 300 mm, for lids = JIS A5182 plate thickness: 0.25 mm plate size: 200 × 300 mm) are sprayed. Afterwards, wash off the residual alkali substance on the surface with tap water.

[0160] (treatment of aluminum alloy plate)

[0161] Use the surface trea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com