Micrometre level arachidonic acid emulsion and preparation thereof

A technology of arachidonic acid emulsion and arachidonic acid, which is applied in the field of micron-scale arachidonic acid emulsion and its preparation, can solve the problems of cumbersome use process, easy oxidation, and difficulty in mixing uniformly, so as to reduce production and application The cost, the production process is simple and feasible, and the effect of good dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

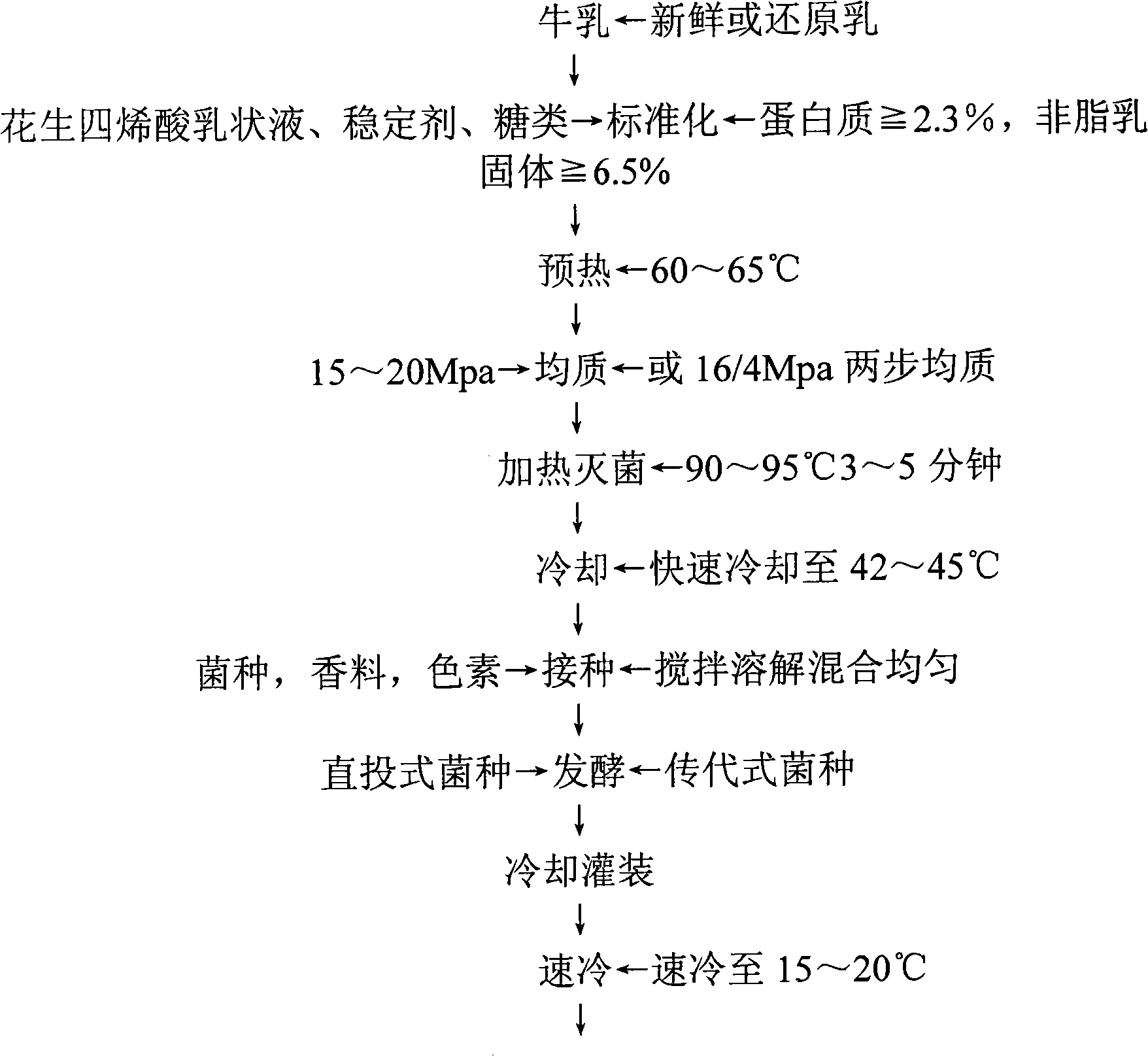

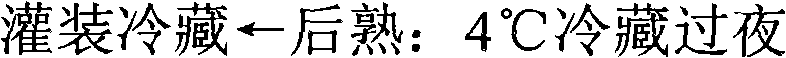

[0044] The preparation method of micron grade arachidonic acid emulsion, the steps are:

[0045] 1) Oil phase part: add arachidonic acid oil with a concentration higher than 40% into the oil phase emulsifier and antioxidant according to the above weight ratio, and heat the oil bath to 50-70°C to dissolve it to make an oil phase product A;

[0046] 2) Water phase part: Add water phase emulsifier, stabilizer and dispersant into water according to the above weight ratio, fully stir, heat to 60-90°C, keep for 20-60min, and make water phase product B;

[0047] 3) After the temperature of the water phase product B drops to 50-80°C, slowly add A to B, perform primary emulsification with a high-speed shearing machine, and obtain product C;

[0048] 4) pressure homogenize product C to obtain product D;

[0049] 5) The product D is sterilized and cooled to obtain the product E, which is an arachidonic acid emulsion.

[0050] In the preparation method of the emulsion, the sterilizatio...

Embodiment 1

[0055] Embodiment 1 contains the preparation method of ARA50g / kg emulsion:

[0056] Take by weighing 130 grams of mixed fats and oils with 40% arachidonic acid content, 0.1 gram of antioxidant (comprising natural vitamin E 0.04 gram, ascorbyl palmitate 0.06 gram), 10 grams of oil phase emulsifier (comprising 6 grams of lecithin, single 4 grams of glycerides), they are mixed while heating, and when the temperature rises to 65°C, they are immediately transferred to the water phase (water phase temperature is 75°C for 40 minutes, and then cooled to 65°C), and the water phase is emulsified 5 grams of agent (including 3 grams of sucrose fatty acid ester, 2 grams of Tween 60), 10 grams of dispersant (including 10 grams of maltose) and 60 grams of thickening and stabilizing agent (including 50 grams of gum arabic and 10 grams of xanthan gum), Supplement to a total amount of 1000 grams with deionized water. Slowly add, stir while adding, after complete addition, use a high-speed sheare...

Embodiment 2

[0057] Embodiment 2 contains the preparation method of ARA50g / kg emulsion:

[0058] Take by weighing 130 grams of mixed fats and oils with 40% arachidonic acid content, 10.05 grams of antioxidants (comprising natural vitamin E4.05 grams, 6 grams of ascorbyl palmitate), 40 grams of oil phase emulsifiers (comprising 24 grams of lecithin, single 16 grams of glycerides), they are mixed while heating, and when the temperature rises to 65°C, they are immediately transferred to the water phase (the temperature of the water phase is 75°C for 40 minutes, and then cooled to 65°C), which contains an emulsifier of 22.5 gram (comprising 13.5 grams of sucrose fatty acid ester, 9 grams of Tween 60), 105 grams of dispersant (comprising 105 grams of maltose) and 180 grams of thickening and stabilizing agent (comprising 150 grams of gum arabic and 30 grams of xanthan gum). Ionized water was added to a total of 1000 grams. Slowly add, stir while adding, after complete addition, use a high-speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com