Great temperature rising absorption type heat pump units

A technology of absorption heat pump and heat pump unit, applied in adsorption machines, heat pumps, refrigerators, etc., can solve the problems of low energy utilization efficiency, complicated operation and adjustment, and large investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

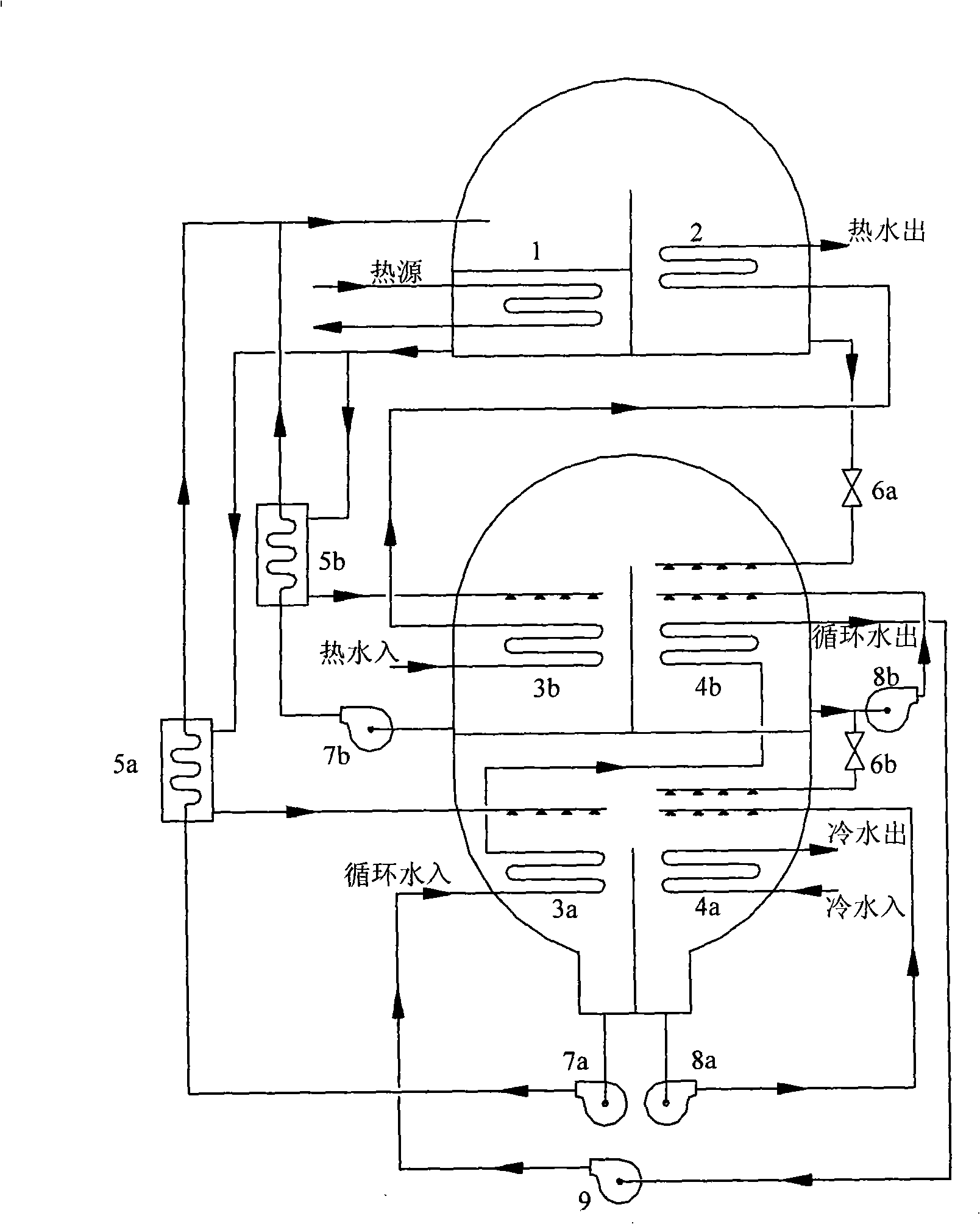

[0019] Example 1: Parallel cycle large temperature rise absorption heat pump unit. Such as figure 1 As shown, the heat pump unit has generator 1, condenser 2, primary absorber 3a, primary evaporator 4a, primary solution heat exchanger 5a, secondary absorber 3b, secondary evaporator 4b, secondary solution Heat exchanger 5b, primary throttling device 6a, secondary throttling device 6b, primary solution pump 7a, secondary solution pump 7b, primary refrigerant pump 8a, secondary refrigerant pump 8b, circulating water pump 9 and connections Main components such as pipelines. Wherein, the pressure of the primary evaporator 4a is lower than the pressure of the secondary evaporator 4b, and the pressure of the secondary evaporator 4b is lower than the pressure of the condenser 2. The dilute solution is heated and boiled by the heat source in the generator 1 to generate refrigerant vapor, and the concentration of the dilute solution increases to become a concentrated solution, which f...

Embodiment 2

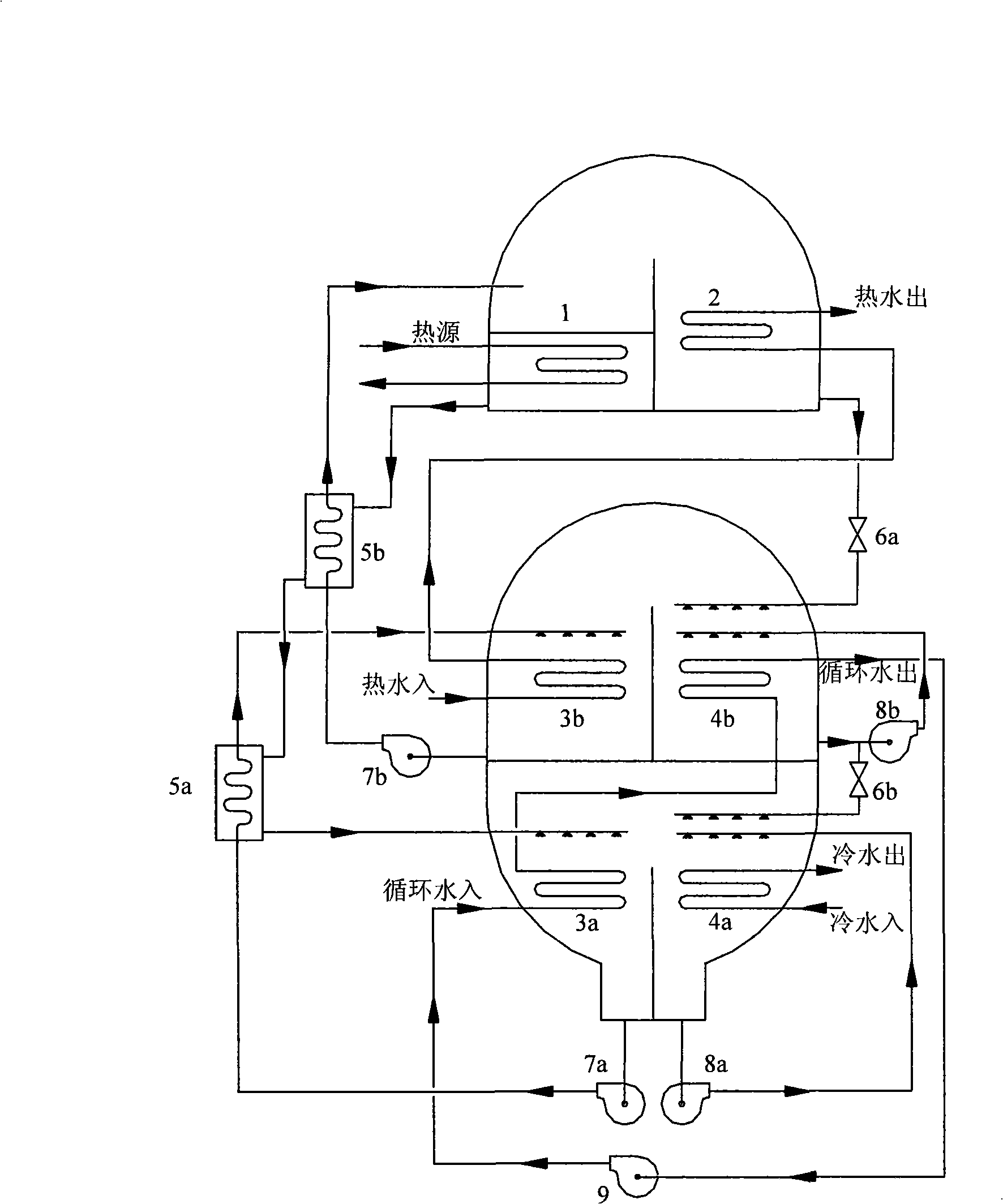

[0020] Example 2: Inverted series cycle large temperature rise absorption heat pump unit. Such as figure 2As shown, the heat pump unit has generator 1, condenser 2, primary absorber 3a, primary evaporator 4a, primary solution heat exchanger 5a, secondary absorber 3b, secondary evaporator 4b, secondary solution Heat exchanger 5b, primary throttling device 6a, secondary throttling device 6b, primary solution pump 7a, secondary solution pump 7b, primary refrigerant pump 8a, secondary refrigerant pump 8b, circulating water pump 9 and connections Main components such as pipelines. Wherein, the pressure of the primary evaporator 4a is lower than the pressure of the secondary evaporator 4b, and the pressure of the secondary evaporator 4b is lower than the pressure of the condenser 2. The dilute solution is heated and boiled by the heat source in the generator 1 to generate refrigerant vapor, and the concentration of the dilute solution increases to become a concentrated solution, ...

Embodiment 3

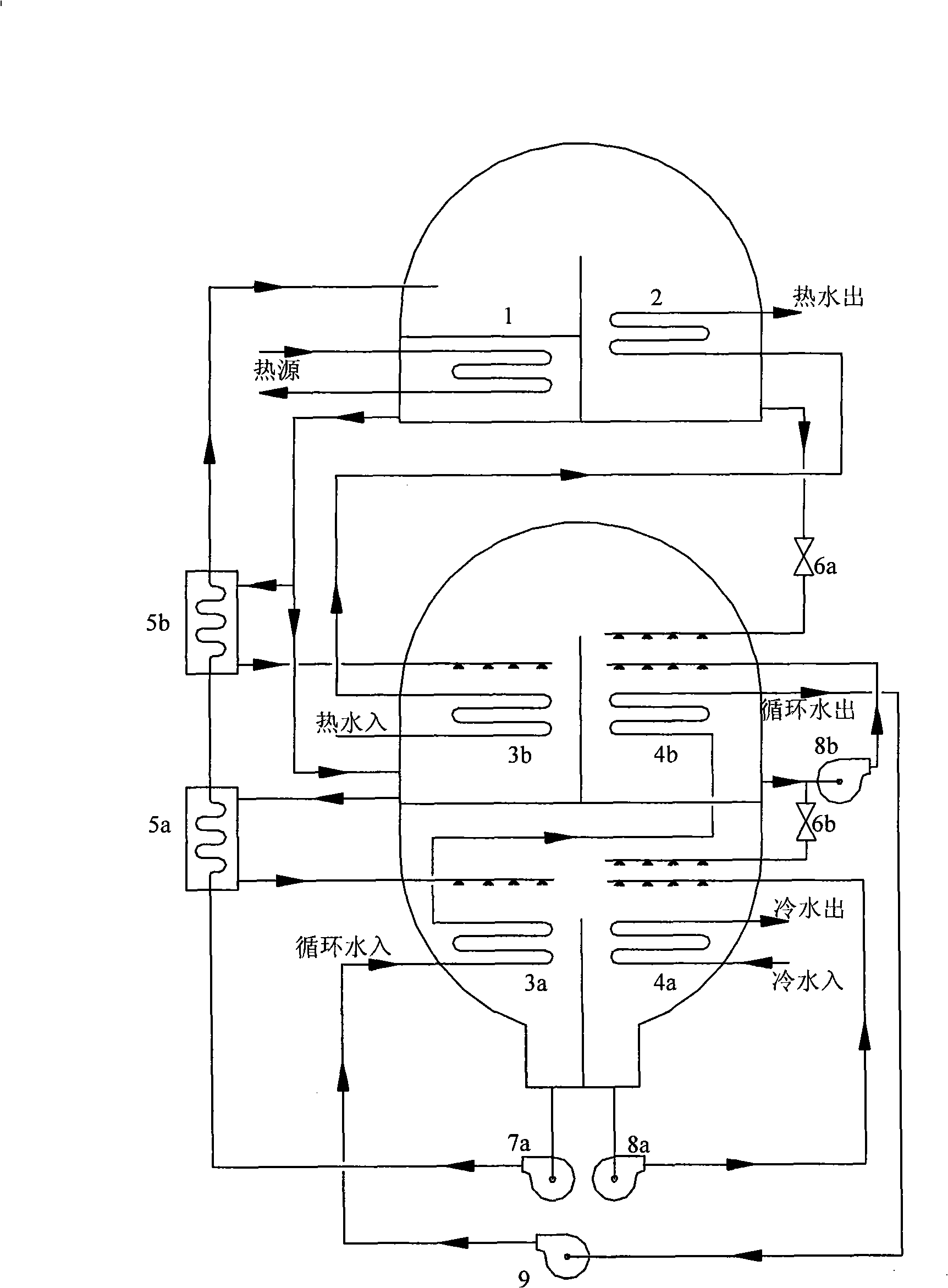

[0021] Embodiment 3: Series-parallel cycle large temperature rise absorption heat pump unit. Such as image 3 As shown, the heat pump unit has generator 1, condenser 2, primary absorber 3a, primary evaporator 4a, primary solution heat exchanger 5a, secondary absorber 3b, secondary evaporator 4b, secondary solution Heat exchanger 5b, primary throttling device 6a, secondary throttling device 6b, primary solution pump 7a, primary refrigerant pump 8a, secondary refrigerant pump 8b, circulating water pump 9 and connecting pipelines and other main components . Wherein, the pressure of the primary evaporator 4a is lower than the pressure of the secondary evaporator 4b, and the pressure of the secondary evaporator 4b is lower than the pressure of the condenser 2. The dilute solution is heated and boiled by the heat source in the generator 1 to generate refrigerant vapor, and the concentration of the dilute solution increases to become a concentrated solution, which flows out of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com