Headlight for motor-driven vehicle

A technology for headlights and motor vehicles, which is applied in the direction of headlights, vehicle lighting systems, lighting devices, etc., can solve the problems of lower light energy utilization rate, large light-gathering capacity, and difficult processing, so as to improve processing quality, The processing technology is simple and the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

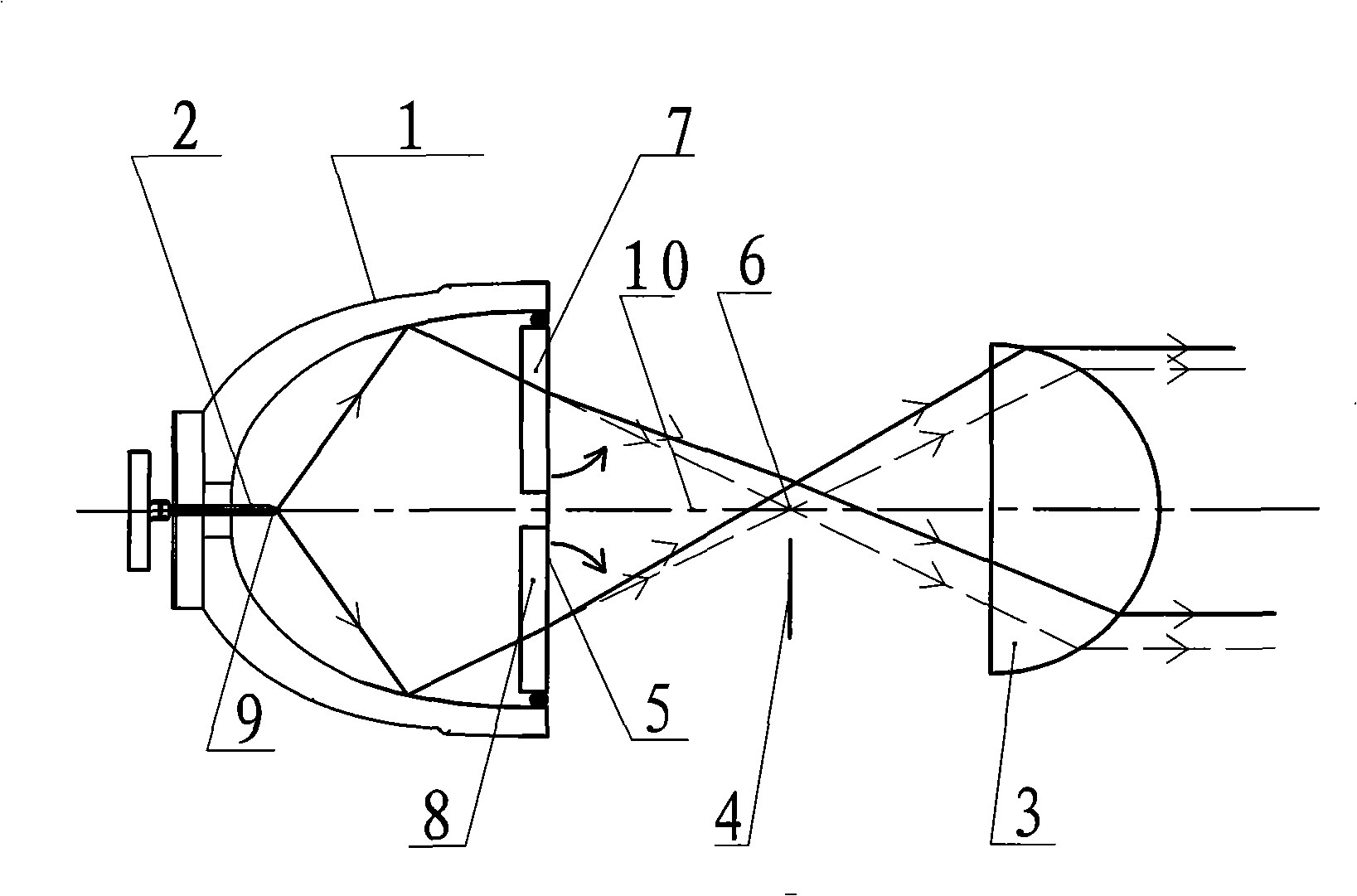

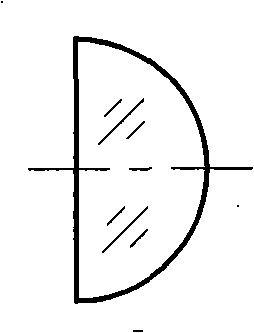

[0032] Such as figure 1 The headlamp of the motor vehicle shown in the present invention includes a reflector 1. The reflector 1 is a rotating elliptical single-curved reflector. A light source 2 is provided in the reflector 1, and the light source 2 is arranged on the first focus 9 of the reflector 1 A condenser 3 is provided in front of the reflector 1. The focal point of the condenser 3 overlaps with the second focal point of the reflector 1. A baffle 4 is provided between the reflector 1 and the condenser 3, and the baffle 4 is arranged on the second focal point of the reflector 1. Below the two focal points 6, and above the end surface 5 of the mirror 1 and above the optical axis 10, there is a low-beam horizontal refraction cylindrical lens 7, such as Figure 7 , 8 The low-beam horizontal refraction cylinder 7 shown in, 9 and 10 is a combination of a screw cylinder and a wedge lens; the wedge lens is set on one side of the light incident direction, and the screw cylinder ge...

Embodiment 2

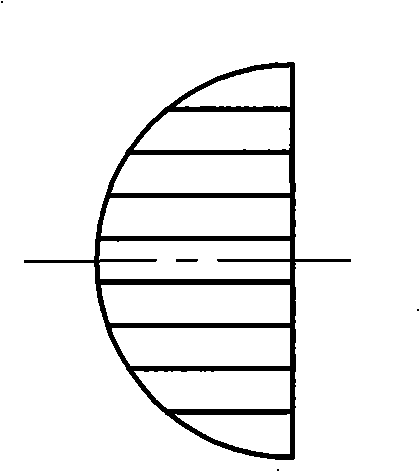

[0035] The low-beam horizontal refraction and brightening cylindrical lens 8 is provided below the low-beam horizontal refraction cylindrical lens 7 in Embodiment 1, and the low-beam horizontal refraction and brightening cylindrical lens 8 is arranged under the end surface 5 of the reflector 1 under the optical axis 10, such as Picture 11 , 12 The low-beam horizontal refraction and brightening cylindrical lens 8 shown in and 13 is a combination of a threaded cylindrical lens and a wedge-shaped lens. The low-beam horizontal refraction and brightening cylindrical lens 8 is driven by an electromagnet; the low-beam horizontal refraction and brightening cylindrical lens 8 is a wedge-shaped lens The wedge angle of is larger than the wedge angle of the low-beam horizontal refraction cylindrical lens 7, and the angle between the wedge lens ridge 12 and the threaded cylindrical lens generatrix 11 is 45°, such as Figure 5 The condenser lens 3 shown is a meniscus lens. Others are the same ...

Embodiment 3

[0037] The low-beam horizontal refraction cylindrical lens 7 in the second embodiment is arranged above the optical axis 10 halfway between the end surface 5 of the mirror 1 and the second focus 6 of the mirror 1, and the low-beam horizontal refraction and brightening cylindrical lens 8 is arranged above the optical axis 10 Below the optical axis 10 halfway between the end surface 5 of the mirror 1 and the second focus 6 of the mirror 1, as image 3 The low-beam horizontal refraction cylindrical lens 7 and the low-beam horizontal refraction and brightening cylindrical lens 8 shown are convex cylindrical lenses, and the baffle 4, the low-beam horizontal refraction cylindrical lens 7 and the low-beam horizontal refraction and brightening cylindrical lens 8 are driven by a motor. Others are the same as in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com